Stamping, forging, and spinning are commonly used metal processing techniques. Did you distinguish the similarities and differences between them?

Common points of stamping, forging, and spinning

Principus est quod pressus ad metallum in molo, cum alto efficabilitate et velocitate processionis est. Omnes moldas quaerunt, quæ generalmente cari sunt processi, sed semel successo processi poterunt masculini produci.

Diagramma

The technical requirements are high, generally requiring master mold technology and requiring significant investment, while forging requires even more investment. The machines used for processing are mostly mechanical or hydraulic presses, which may look similar to outsiders with many similarities. However, there are many differences in equipment structure and practical applications. They are all processing techniques and don't produce their own independent products. Stamping, forging, and spinning provide several or even hundreds of products for downstream users. Constrained by downstream demand, they are only a small link in the midstream of the industry chain and generally don't have pricing power. Differentiae inter stampionem, fabricationem, et spinam

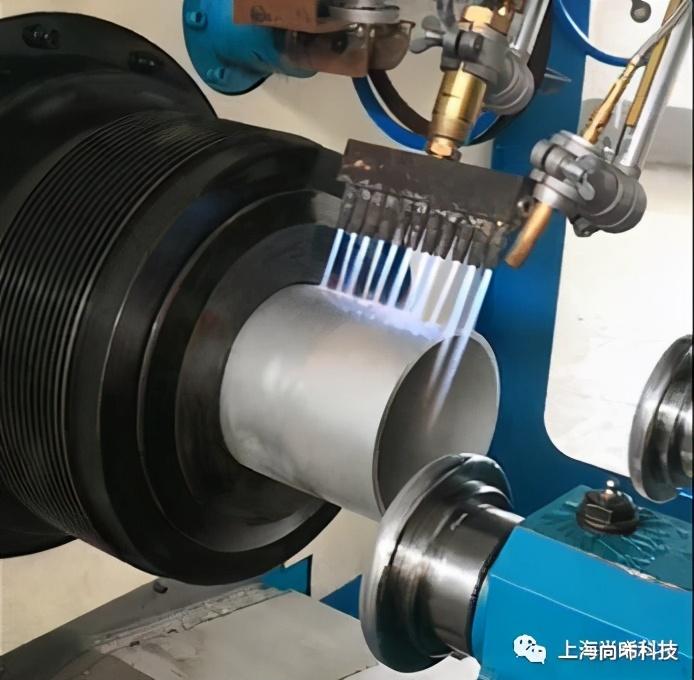

Stamping is basically cold processing, of course, there are also hot stamping, but it is relatively rare; Forgettio basically calide est et requirit calefacere de processione materia, et formacio frigido, sed etiam post completionem calefactio requirit. Spinning generale dominatur a processione frigida, sed in processione ipsa materia calefacetur.  hot spinning processing

hot spinning processing

Forging involves volume deformation, changes in metalla structure, and processing of three-dimensional load-bearing components, such as crankshafts and connecting rods in engines; Stamping is the deformation of sheet metal, which generally does not involve internal crystal changes, but only the thickness and tensile deformation of the sheet metal. The processed stamped parts are subject to stress and not, and have a wide range of applications. Spinning combines the deformation methods of stamping and forging, which can change the volume (shape) of materials and also alter their thickness through stretching. Conditiones operantium in laboratorio fabricationis relative difficile et sordidi sunt, cum magno sono, et odor fornacium industriae calefactionis ardentes, graphite frigidae, scala oxide et ceteris odoris; Laboratorium pulcherrimae melior est, sed propter collisionem machinarum pulcherrimae supra et desuper, sonus etiam non parvus est. Environment in spinning workshop is relatively good. Most spinning machines have protective doors that can isolate some noise, and there is little or no waste generated. From the perspective of workers, traditional factories are monotonous and boring, stamping automation is common, forging is relatively difficult, and spinning mostly relies on CNC technology, which does not require high demands on workers. Nequaquam de tecnologia processionis, fabricationis industriae est. Manufacture est essential and important foundational industry that is closely related to people's livelihoods. So we need to fully use the characteristics and advantages of each process to manufacture high demand products and enhance the overall industrial capacity of the country.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque