Concerno annotation is dimensionis, multi novi artificii technici in industria drawingem habent et volunt annotati dimensiones, sed nescient quomodo incipire et quomodo eos perfecto exprimere. Est autem modus popularis aut modus suitus initoribus?

Generale loquente, drawinges non sunt perfecti, et omnis qui creat aliquid formam drawing is semper potest eicere varias defectus. Etiam si putas non esse problemas cum drawinge, dum revisione principis, non petitur te modificare aliquid inmaculatos problemas, aut si putas quod rectum est, sed necesse est modificare secundum instruktiones principis.

For drawings, generally speaking, the more information there is, the more redundancy there is, and in a certain extent, it can also affect information exchange.

Omne dimensiones rationale annotare, necesse est intellegere functionem parterum, positionem congregationis eorum in maquina, et metodes processionis utilis, ut elegere benchmarkos dimensionales adequatos et dimensiones rationale annotare.

Eğer bu kuralını anlarsanız, hatta en kompleks ürün boyutlu etiketlemesi bile kaybetmeyecek.

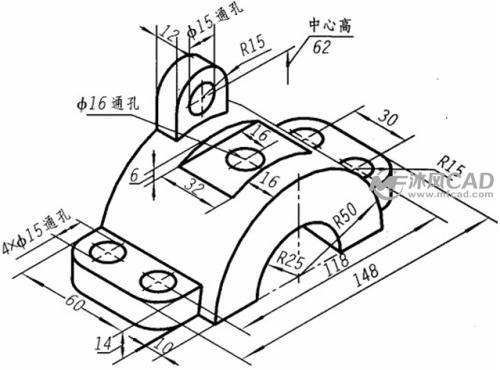

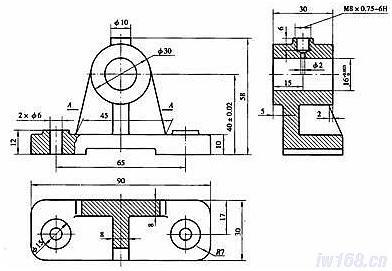

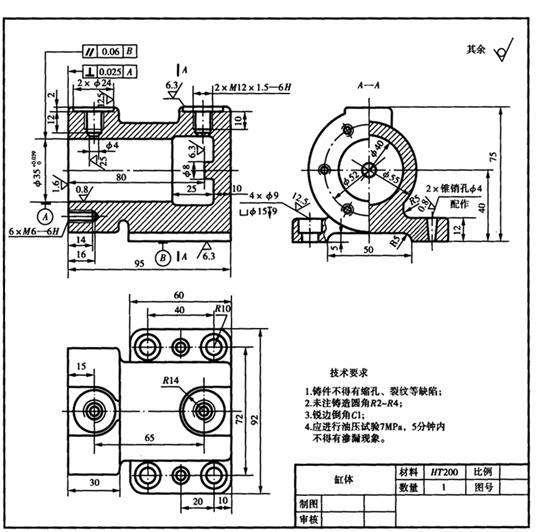

Classify and explain various complex mechanical components drawings, how to label dimensions reasonably

Principle dimensionis rationalis: 1. dimensiones importantes directe indicantur

2. Avoid labelling as a closed dimensional chain

3. Consideration should be given to the convenience of measurement

4. Respondere sequentiae processionis

5. Considere processiones metodes

6. Dimensional annotation method for common holes on parts

Common knowledge of mechanical drawing: dimensioning of part drawings, selection of benchmarks, and principles of reasonable annotation

The basic points to note for other drawings are:

1. Fill in all possible fields in the frame, including name, number, scale, material, unit, weight, surface treatment, signature, etc.

2. Mark the dimensions and tolerances one by one, while highlighting the key points (3F dimensions, quality control points). Tolerantia in conjunction with the production capabilities of the company must be studied, and cannot be marked for tolerance.

3. Communicate with the users of the drawings (processors, quality controllers, bosses, etc.) to discuss and approve some of their important feedback, which can be written on the drawings.

4. Bonum. Visus maximus est maximus maximus possibilis; Multi colores utilizat, sicut unum colorem ad markum dimensionis et alium colorem ad markum positivam tolerantiam; Sometimes using dimension chains for annotation can reduce the clutter of drawings.

5. Proicite facere figuras in ženieriis ex modelis 3D, et includere individuas perspektivas, quas melius possunt viscerare stilum componentium in drawingibus.

Resolve the issue of increased annotation size in CAD local enlargement icons

Definition, annotation, and interpretation of various positional tolerances - truly comprehensive

Introduction to Calculation and Application of Size Chain: When designing and annotating dimensions in products, it is necessary to consider

Differentia inter tres metodes annotationis: 10 (-0.2,+0.2) 9.8 (0,+0.4) 10.2 (0, -0.4)

Detailed explanation: Gap, transition, interference fit, base hole system, base axis system, fitting code and annotation examples

Mechanical drawing: Which of the four identical hole markings 4-10 and 410 is correct?

Don't say you can't understand the drawings anymore! Non technical personnel related to machinery should take a good look at the most basic drawing annotations

Mechanical Drawing: Detailed Explanation of the Concept and Annotation Method of Surface Roughness

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque