In order to control the cooling temperature of refrigeration equipment such as refrigerators and air conditioners and the heating temperature of electric heating devices, temperature controllers (referred to as thermostats) are installed on both refrigeration equipment and electric heating devices.

1,Classification of Temperature Controllers

1. Classification based on control methods

Thermostat in duos typos dividi potest in manibus eorum controllis: mechanica et electronica. Mechanical temperature controllers detect temperature through temperature sensors and control the compressor power supply system through mechanical systems, thereby achieving temperature control. Electronic temperature controllers detect temperature through negative temperature coefficient thermistors, and then control the compressor power supply system through relays or thyristors to achieve temperature control.

2. Classification based on material composition

Thermostats can be divided into various types based on their material composition, such as bimetallic thermostats, refrigerant thermostats, magnetic thermostats, thermocouple thermostats, and electronic thermostats.

3. Classifica per function

Temperature controllers can be divided into various types based on their functions, such as refrigerator temperature controllers, air conditioner temperature controllers, rice cooker temperature controllers, electric water heater temperature controllers, shower temperature controllers, microwave temperature controllers, barbecue oven temperature controllers, etc.

4. Classifica secundum modum opus contactorum

Name

2,Identification and detection of bimetallic thermostat

Bimetallic thermostat, also known as temperature control switch, is mainly used to control the heating temperature of electric heating devices. Visura fisica thermostati communa in sequente figura monstrata est.

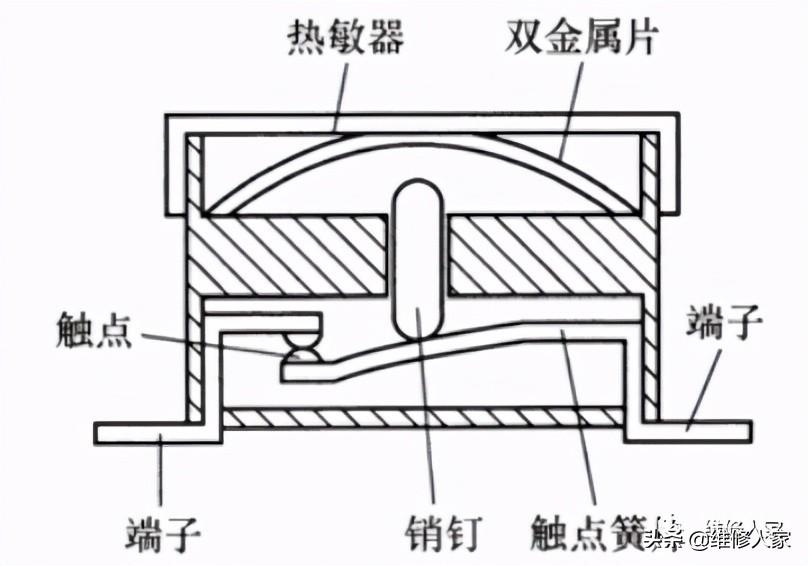

1. Composition and principle of bimetallic thermostat

Bimetallic thermostat ex thermistoro, bimetallic strips, pins, contacts, contact springs etc., sicut in sequente figura monstratus est. Postquam apparatus calefactionis electricae activatus est, incipit calefacere. Quando temperatura ab thermostate minima est, bimetallisque structura supra crescet sine connexio pinci, et contactus sub actione fonti kontactionis claudet. Cumque calefactor continuat, quando temperatura ab thermostat detecta fuerit, varia bimetalica deformit et pressit, causat fontem kontacti subvertere per pinnum, resultat in release kontacti. Calefactor cessat laborare propter defectum supply potentiae, et apparatum calefactoris electricum intrat in insulationem statum. Cum insulatio tempore prolongaverit, temperatura diminuere coepit. Postquam testator temperaturae inveniet, fluctus bimetallis eius resetat, et contacti ab prima fons attracti sunt. circuitus energiae calefactoris refectus est ad initium calefactionis. In repetitione superioris procedentibus, controllum automaticam temperaturae conplebitur.

Tip: The control temperature point of the bimetallic thermostat used in some rice cookers can be adjusted. Adjusting the adjustment screw on the bimetallic thermostat, the pressure acting on the contact can be changed in advance, thereby changing the temperature point of the action.

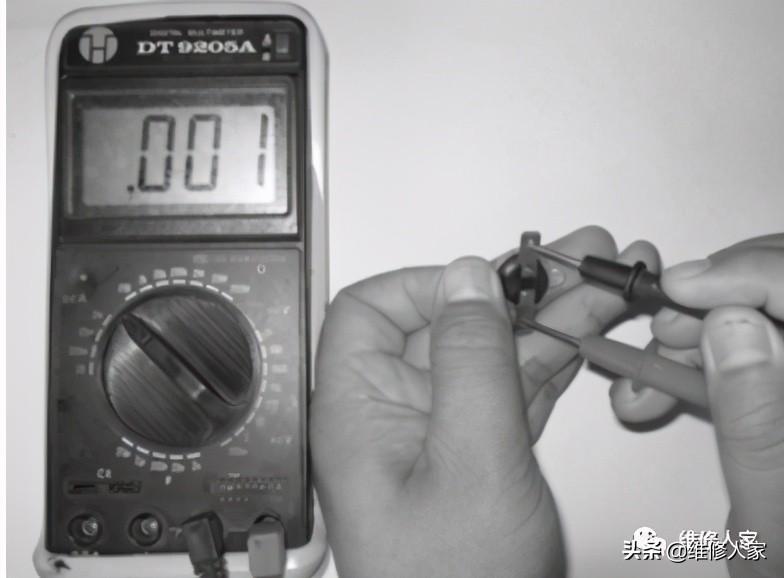

2. Testum bimetallic thermostat

Ut in figura inferiora, cum non calefactus, utilizat "R1" positionem multimetri ut mensuram resistentiam inter terminalis variationis thermostat is bimetallici. Si resistentia infinita est, indicat quod circulum apertum est. Et quando temperatura eius adprehenderit nominalem, valor resistentiae infinitus non potest esse et nullus manet, indicantes quod interiores contaminati sunt.

3,Identification and Testing of Magnetic Temperature Controllers

Magnetic temperature controller, also known as magnetic steel temperature limiter, commonly known as magnetic steel, is mainly used in rice cookers to control the cooking time of the rice cooker. Visura physica thermostati communa in imagine monstrata est.

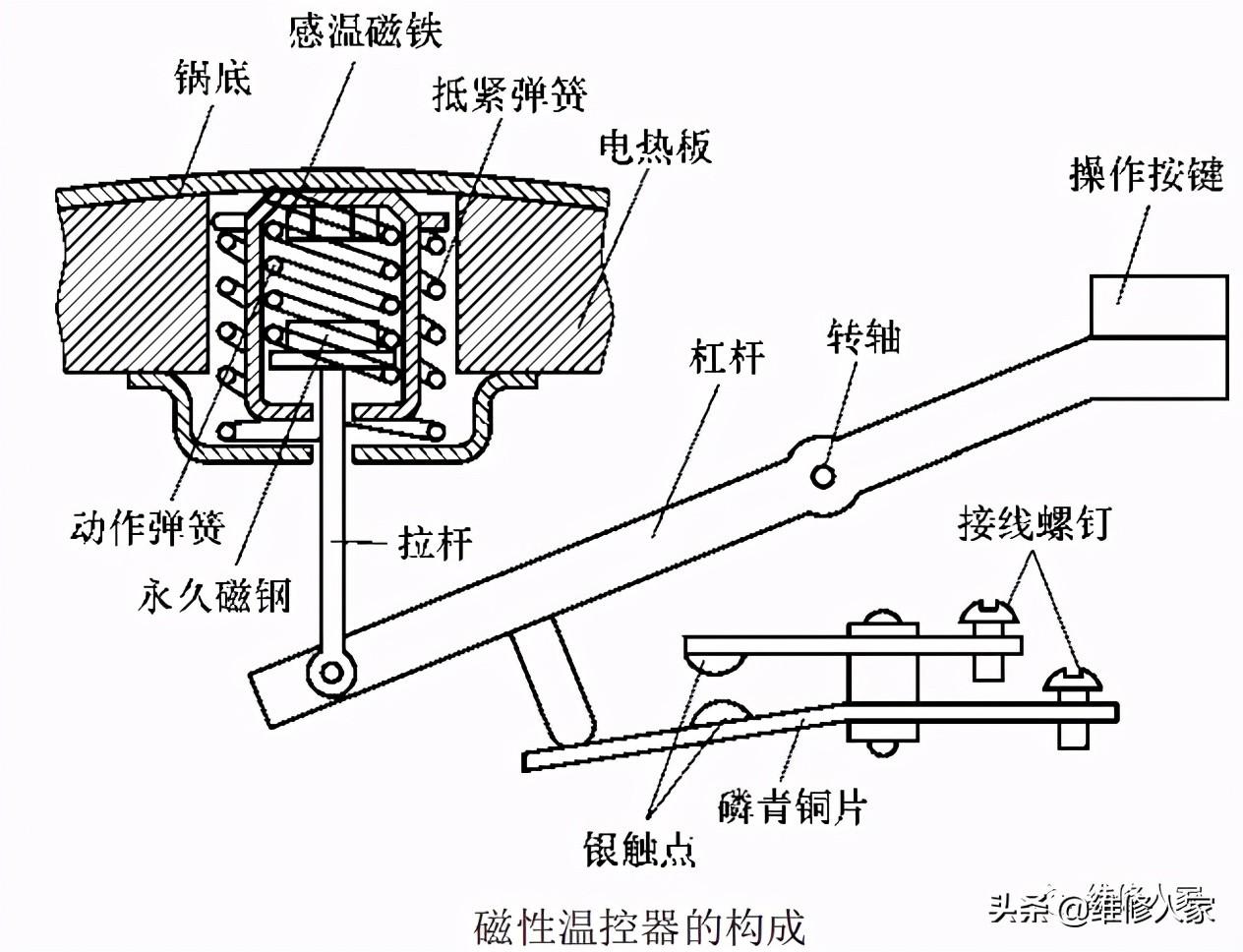

1. Composition of magnetic thermostat

The magnetic thermostat is composed of temperature sensing magnets, springs, permanents magnets, pull rods etc., as shown in the following figure.

2. Working principle of magnetic thermostat

Post pressionem botonis coctoris oris, magnetum sempiternum intra thermostatam magneticam conprehendit foras pulseris action is sub actione leveris, movet supra et attrahet magnetum sensationis temperaturae. Contractus argentis excussionis ecclesiae clausus est sub actione folii bronze phosphoris, connectant circuitum energiae fornicationis plateae calefactionis oris, et calefacet. Cum calefactus continuat, temperatura subter ollam graduum crescet. Quando temperatura adpropinquat magnetum sensationis temperaturae, magnetum sensationis temperaturae desaparit, magnetum sempiternum sub actione germinis action is resetat. Contractus a levario disconnectus est, et calefactor cessat operare propter deficitum supply potentiae. Cooctor oriosus intrat in insulationem statum.

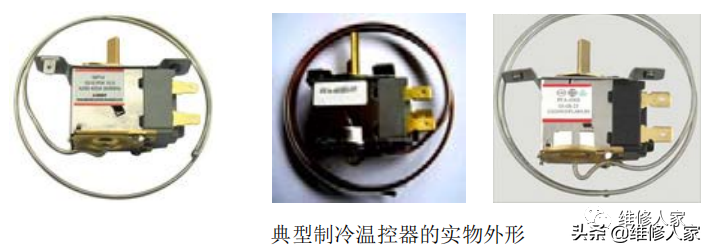

4,Identification and Testing of Refrigeration Temperature Controllers

The refrigeration temperature controller (mechanical type) is mainly used in ordinary direct cooling refrigerators. Its main function is to control the operation and stop time of the compressor, and achieve refrigeration control. Aspectus physicus frigidarii thermostati communae in sequente figura monstratur.

1. Composition of refrigeration temperature controller

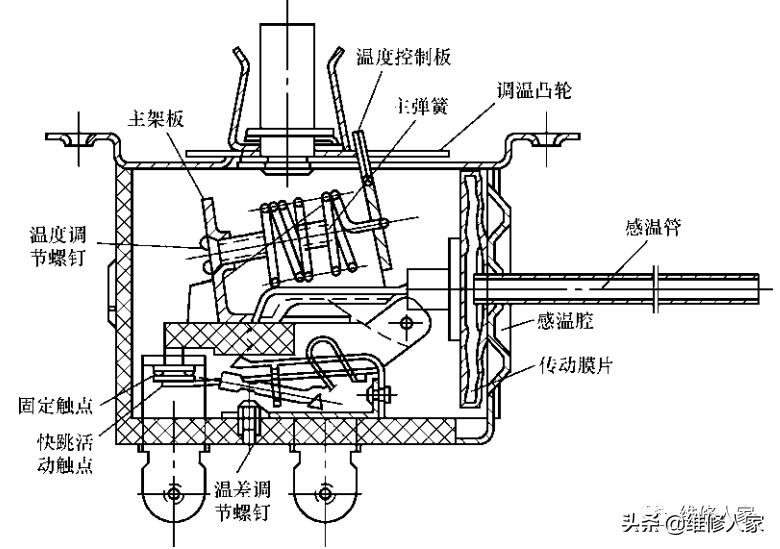

Temperatura refrigeration is (typus mechanicus) principium ab tuba sensoris temperaturae, diaphragm transmissionis, angularibus adjustationis temperaturae, contactos etc., sicut in sequente figura monstratus est

2. Working principle of refrigeration temperature controller

Quando temperatura intra frigidarium alta est, temperatura tubae sensationis temperaturae installae super superficiem refrigerator is evaporatoris etiam crescit. Extensione agentis sensationis temperaturae intra tubam crescit pressionem, causa diaphragm transmissionis ante gazofilacium sensationis temperaturae (sacco sensationis temperaturae) ante faciem movere. Quando attinget temperaturam, contatus movens (contatus velox saltabilis) et clausus contactus fixius, connexio circuitu energiae compressoris motoris. Compressor operare coepit, et refrigerator intrat in state frigidarii. Cumque refrigeratio continuat, temperatura superficie evaporatoris graduale diminuit, et temperatura et pressio tubae sensoris temperaturae etiam diminuit. Diaphragm transmissionis retrorsum movet. Cum ad quaecum temperaturam attinget, contunctus movens separat a facie fixa sub actione prima foris, circuitu energiae compressoris, constituit compressorem et refrigeratorem finit. Repeat supra processum, temperatura controllor tempore compressoris operationem controlat ut certat temperaturam intro cista intra quaecum intervallo variatur. Controlum temperaturae intra frigidarium attingetur per rotationem temperaturae adjustationis. Quando amplius temperaturae non adequat necessitatibus (error est in controllo temperaturae), corrigere potest a adjusto temperaturae adjustationis. However, don't adjust it during general maintenance, especially for thermostats with defrosting devices, to avoid unnecessary trouble.

3. Testing of refrigeration temperature controller

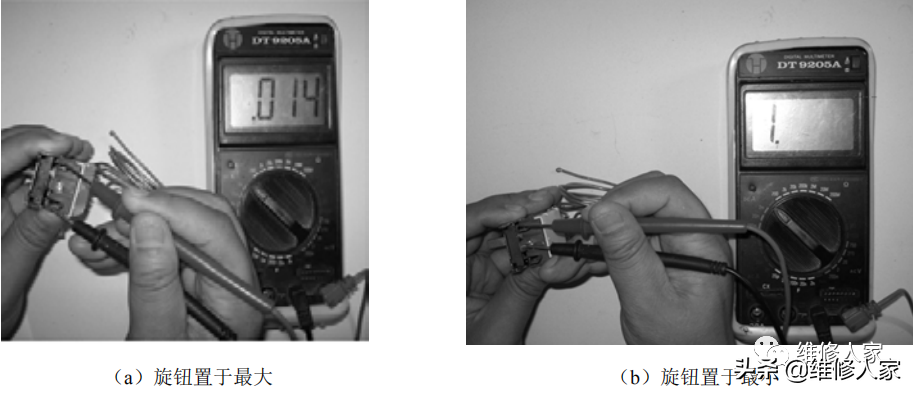

Postquam pulchritudinem thermostati in maximum extinguisset, modus diodis (modus mensurae/extinguisse) multimetri digitalis ut mensuram valorem inter terminos contactorum quasi 0 aut proximum 0, et pulchritudinem sonabit, sicut in (a) supra monstratus est; Si pulchra thermostat is maxima conversa est et valor nulla esse non potest, significat contactos thermostatis claudere non potest. quando pulvis thermostati convertitur ad minimum suum valor infinitus erit sicut in b) supra monstratus est Si valor est 0, indicat quod contacti intra thermostat obstructi sunt.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque