It may sound clich é, but indeed, prevention is better than cure. Hoc verum est pro omni fabricatione, sublime in industria stampionis metallis. Metali vestibus, corrosionibus, periculis videntibus et aliis factoribus effecti sunt. Multi procesi in stampionis adiuvant minimizare haec potential is defectus metallorum - unus ex eis est tractatus superficie metallorum aut finitum metallorum, quod ultra protectum metallorum possit.

Est nobis beneficius et essential intellegens applicationem eius super metallos (dependant on its corrosiveness, potential exposure, etc.). In longo tempore terra superficie nobis plus pecuniam et minus tempus productionis salvabit. This article will delve into the importance, advantages, and common types of metal surface treatment.

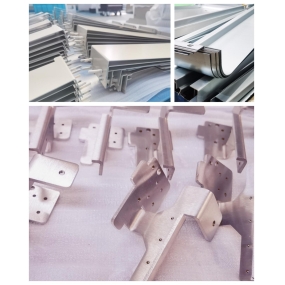

What is metal surface treatment? Metal surface treatment is the creation and application of a layer or physical barrier to protect the metal before coating occurs. Haec processus mundare metallos, deburring, polishing etc. It can not only increase the structural integrity of the metal, but also enhance these parts or components aesthetically.

But of course, there are some factors to consider when performing metal surface treatment, such as production speed, cost-efficiency, and metal durability. Vos certa est omnia ad captiones companiis et adplicationem partes metallorum alligatum esse. Et propter hoc consilium propositur a fabricatione metallicorum ad superficium tractamen.

In order to continue learning, the following steps are the steps for metal surface treatment:

First, you need to clean the surface from the stamping compound and grinding oil. Then, apply organic or inorganic sealant. Anulus cum aqua deionizata. Finally, to remove moisture, you can place it in a oven or air dry it. Cur fertilium superficie metallis opus est? crucial est ad producendum et designandum partes metallicis metallicis. Therefore, it is necessary to plan surface treatment options. Haec processus crescit vitam servitutis metallorum, et illum graviorem facit in aliis industriis. In addition, it can expand your company as you know you are providing high quality stamped parts.

In addition to the above statement, there are many reasons why we should perform surface treatment on metals, all of which are worth understanding.

Corrosion inhibition - Non rusting metals are a good indication of reliable materials suitable for any application. Praecipientes partes excelsam corrosionem resistentiam ad galvanicam corrosionem, corrosionem et corrosionem crevicem habere oportet. Improve appearance - Surface treatment makes the metal more pleasant and aesthetically balanced for decorative purposes. Mater aut splendens, embossus aut simplex, etc. Improvere durabilitatem - sicut praecepit, potest extendere vitam servitutis metallorum. It can harden the surface of parts, which is highly needed in the production of stamped parts for medical equipment, building materials and automotive parts. Enhanced electrical performance, color resistance, and chemical resistance - these benefits provide impeccable advantages in increasing the value of metals. Utra industria faciem metallorum tractat? Proximo omnia quae videmus, utilizat, et aedificabitur produktus superficie tractionis partium metallorum in universa instrumenta componentibus. Companies such as industrial electronics, health care, industry, aerospace, communications, and others use this process to improve their tools, items and equipment.

Exemplo, in industria electronicae, illud ad operimentum, connectores, sensores, pulveres etc., quod videre potestis in telephonis, computatoribus et apparatus mobilibus. In agro medico faciemus terram superficiem in partes laboratorium, sicut pompas, monitores, equipa surgicae, etc.

Haec lista adhuc continuat, quoniam hodie nostra era prima reliquum est servis et procedentibus, etiam stampionis metallorum, ut ferret partes metallorum alta qualitate customizatis.

Now that we have studied the importance and advantages of metal surface treatment, it is time for you to consider selecting the appropriate method for the right materials and related finishes.

As is well known, different materials and products require additional surface treatments. We have many different types, but the following list will show you eight (8) common metal surface treatments for stamping parts that can typically produce high-quality results:

www.dggold.com

www.dggold.com

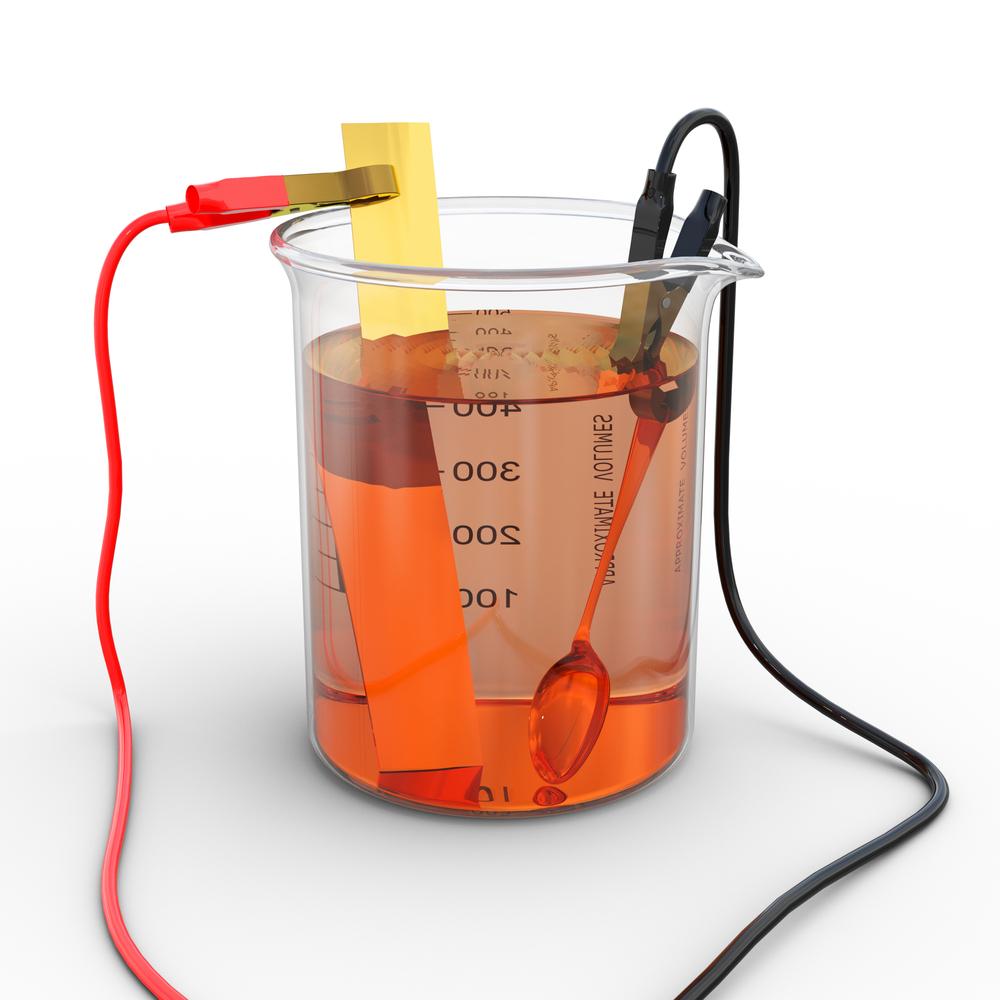

Electroplating est procesus chemicalus, quod involvet applicati metallicum coatingem super superficiem metallicem magnam utilizantem current electricam. Due its versatility - from miniature components to large products - this method is a widely used surface treatment approach. Est aestimatus protegere metallos a corrosione, magnificare faciem et magnificare faciem eorum physicam.

Haec methodo processionis ad partes metallos in laboratoriis, equipamenta medicina, instrumenta domus et automobilis utilizatur. In addition, electroplating is mainly suitable for various metals, such as:

Metali standard (sicut coper, nickel, tin, cinc), metalli pretiosi (sicut aurum, argentum, palladium, rhodium) et chromium durus et electroplating cadmium contra electroplatingam sunt, quoniam electroplating non per currentem exercitur. In contrast, it uses chemical reactions to apply a metal coating on the target metal (or what we call the "substrate"). Classificatio eius lentior et uniformior est quam electroplating. It is also more cost-effective throughout the entire process.

Methus in hoc tractatum superficie est nickel. Haec produkcija multitudinem componentum industriis, sicut aerospace et arma fabricatorum, provident. Chemical plating is also beneficial for stamping metal parts, such as:

Aluminium steel copper zinc bras chemical coating, also known as powder coating, is a surface treatment where a smooth protective film is applied to the substrate by compressed air, resulting in the subsequent melting of the powder material. It makes stamped metal highly scratch resistant and crack resistant, corrosion-resistant, and valuable as a metal coloring agent.

Chemical coatings are widely used in automotive components, making them an ideal choice for customers preferences. In addition, the materials for this surface treatment are aluminum and steel.

Metal anodization is the electrolytic oxidation of metal surfaces to form a protective film of oxide coating. Est valde adequatus quam tractamen superficie metallorum ferre et lacrima minimizare, corrosionem resistere, et componentes metallorum robustiores et complexores facire.

On the other hand, it's not suitable to stamp parts with rough and damaged surfaces, as it can only be uniformly coated. Nunc componentes metallorum aluminium constituetur.

Gulf calidus galvanizans, etiam vestimentum calidum dipus, est terra superficie. vestitur a ferro vitro et ferro lapide in vaso cinco conflatile. Through this treatment, metal components are most likely to have high corrosion resistance. Metodo fertile doping popularissimum est in fabricatione electricorum consumatorum et partes metallorum automoticam industrium.

Vacuum metallization is the process of applying protective metal barriers to smooth stamped parts. Haec tractura superficie fert metallum in caput aut condicio positum et in vestibulo metallo ibi aspersum est. Spellum habet perfectum adequam pro decorativa et design purposes, subito in aerospace et automobilis industriis. Aluminium metallus clavis huius modi est.

Painting and painting have many applications, such as spray painting, electrostatic painting, conductive painting, lubricant painting, etc. Haec tractura superficie optima corrosionem et resistentiam rustis facit, et faciem cunctis partibus metallorum amplificat.

Fertilium termalum, quasi trakta superficie, efficiat capacitatem componentium metallorum ferre aut minimare scrumptas, peeling, et cracking super superficiem metallorum per conflationem et calefactionem vestimenti metallorum. Uter est primum pro magnis partibus metallicis constituentibus.

www.dggold.com

www.dggold.com

Metal surface treatment has a significant impact on Metal Stamping. It can enhance and increase stamping parts in terms of durability, corrosion resistance, aesthetics, and other aspects. In qualitate omnibus fabricatoribus, provisionibus et emissoribus utilit. No wonder this method requires careful planning.

But please note that everyone must be aware of the factors that need to be considered in the metal surface treatment of stamped parts. Ut non necessarii resultationes prohibere, quidam elementos, sicut dura et opus consummare, objecti socii tui et socii tui, et necessaria produkti.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque