Dixit autem molas mater industriae sunt, sed quid iustus est mola continua?

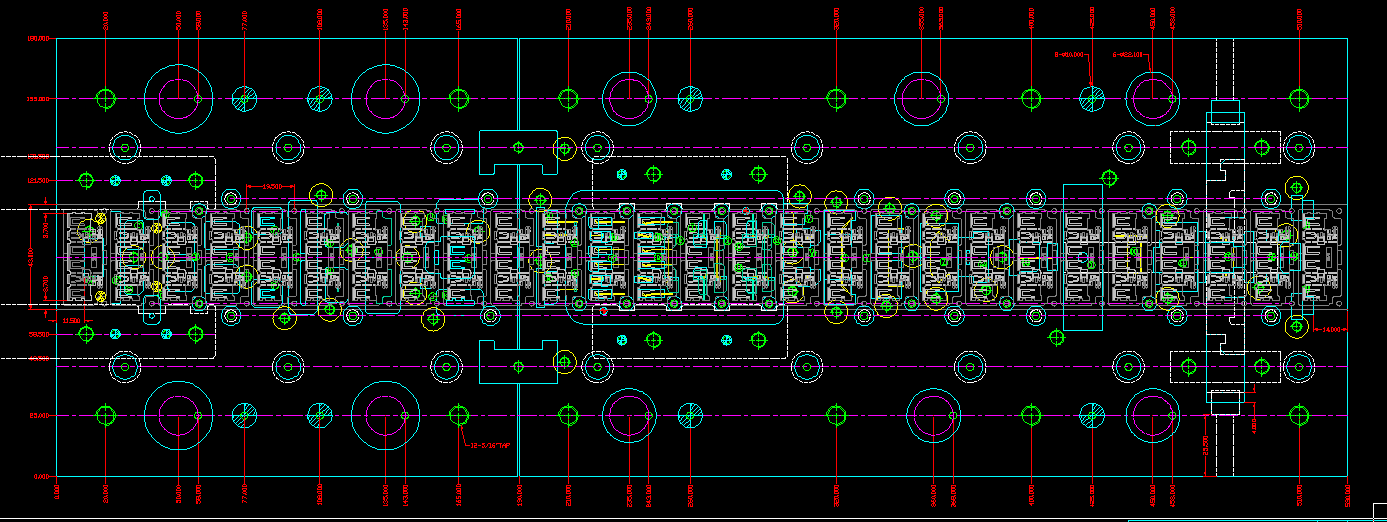

In general, so-called continuous stamping die is the process structure of combining multiple projects in the same die, threading the material cinctura in the die and stamping one step at a time to create a complete hardware.

Stamping Forming: Among various types of stamping molds, continuous stamping molds are most suitable for mass production due to their high production efficiency. Moreover, continuous stamping molds have a wide range of applications and can be used for various hardware parts.

Praeposita constantes mollis pulseris sunt:

1. Producing with coil materials results in lower material utilization and saves the disadvantage of continuous feeding.

2. Engineering and structural design are more flexible.

3. Unus punch can produce multiple PCS, with fast production speed and high efficiency.

4. Sama seta moldovum simul multiproduktos producere potest.

5. Easy to achieve automated production, saving a lot of manpower and material resources.

Confirmation items for the review of finished product drawings before mold design and opening:

1. Edge and rolling direction, finished product material and thickness.

2. Directio ventilationis perpetuum virgae (adtende an electroplating necessaria est).

3. Annotationes clara sunt, et non linguae locales traducentur et annotatentur.

4. Utrum dimensiones et tolerantiae sculpturae perfectae sunt.

5. Quod est modus anguli videntiae, et dimensiones in metrica aut imperiale indicatae.

6. Estne positio extinguentis effectus functionitatis aut assemblationis finis produkti.

7. Utrum duo lateri partis in radice finis produkti simetricae sunt, asymmetry deviationem post bending causa potest, et negotiatum debet cum cliente.

8. Procede functiones utilizacionis produktorum et contentios relatus a clientes maxime possibilis accipere.

9. When the dimensions or tolerances are unreasonable, missing or unclear, the customer must be notified in writing and requested to provide a written response, which should be fully retained for future reference.

Precisiones pro dissolutionibus:

1. Parametrium mensurae logicam esse, ex exemplo, foras et altitudo colligentibus cum summis limitibus ponere debet.

2. Minimum limitum pro angustia formae curvatoris et radice diametri interiori curvatoris constituetur.

3. Quando est requisum pro valore CPK, tolerantia multiplicabitur quando CPK 1.33 est, et multiplicabitur quando CPK 1.67 est

Site postea.

4. Quando necessitates electroplatingae sunt, mensurae antequam et post electroplatingam considerabitur.

5. SUS (stainless steel) O material relatively soft, and there will be a stretching amount when bent above 80 degrees

Attentia quando circa 0.10-0.12 apertura est.

6. When bending and forming in a zigzag shape, there will be a stretching amount, and attention must be paid when opening.

Continuous stamping die design process:

1. Finished product unfolding setting values and bending setting values.

2. Set the direction of finished product burns and rolling direction.

3. Postavite diagramam apertum (tres visiones).

4. Establite diagramam structurae ingenieriae.

5. Discussion meeting on new mold engineering structure.

6. Partibus dissipate et trahende.

7. Legere et drawinge.

Setting of gaps between various materials:

1. Intervallis aeris (C2680) 4% (densitudo material 0.04=granditudo intervallis unilateral is).

2. Spessus coperii phosphor is (C5191/C5210) 5% (densitudo materiae 0.05=granditudo spatiorum unilateralis).

3. Intervallis mensurae tabulae orientalis (C7701/C7521) 5% (densitudo materiae 0.05=granditudo intervallis unilateral is).

4. SPCC/SPCE variatio clara 4% (altitudo material 0.04=granditudo unilateral is spatiorum).

5. Aestula sterilis sterilis (SUS) est 4% (altitudo material 0.04=granditudo unilateral is spatiorum).

6. Intervallis aluminii fluctus est 2% (altitudo material 0.02=granditudo unilateral is spatiorum).

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque