Facilitate metallorum lapides, sicut nomen suggestit, est utilium lapides metallorum ut faceret quae necessaria sunt secundum petitionem. Commonly used materials in daily life include computer case cabinets, TV backboards, car casings, air conditioning casings, terminal integrated casings, charging station casings, etc. What are the processing techniques for Sheet Metal Processing? Editor summarizatus est sicut:

Procedores principibus metallorum procedentium includent cutationem et secationem, CNC bending, punching and shearing, stamping, rolling, riveting, welding and other methods and processes. Utrum principes operantium et manibus operationis diversorum cogitationum esse dicitur. All sheet metal processing techniques require sheet metal engineers to carefully design product drawings and annotate specifications before operation. The technical terms mainly include: cutting, riveting, bending, cutting, dropping, punching, expanding riveting, pulling nut, pulling riveting, riveting, cutting corners, forming, punching convex hull, punching tearing, punching printing, expanding holes, punching mesh holes, chamfering, returning teeth, extracting holes, tapping teeth, leveling, drilling, sinking holes, flattening, welding, spraying, assembly, etc.

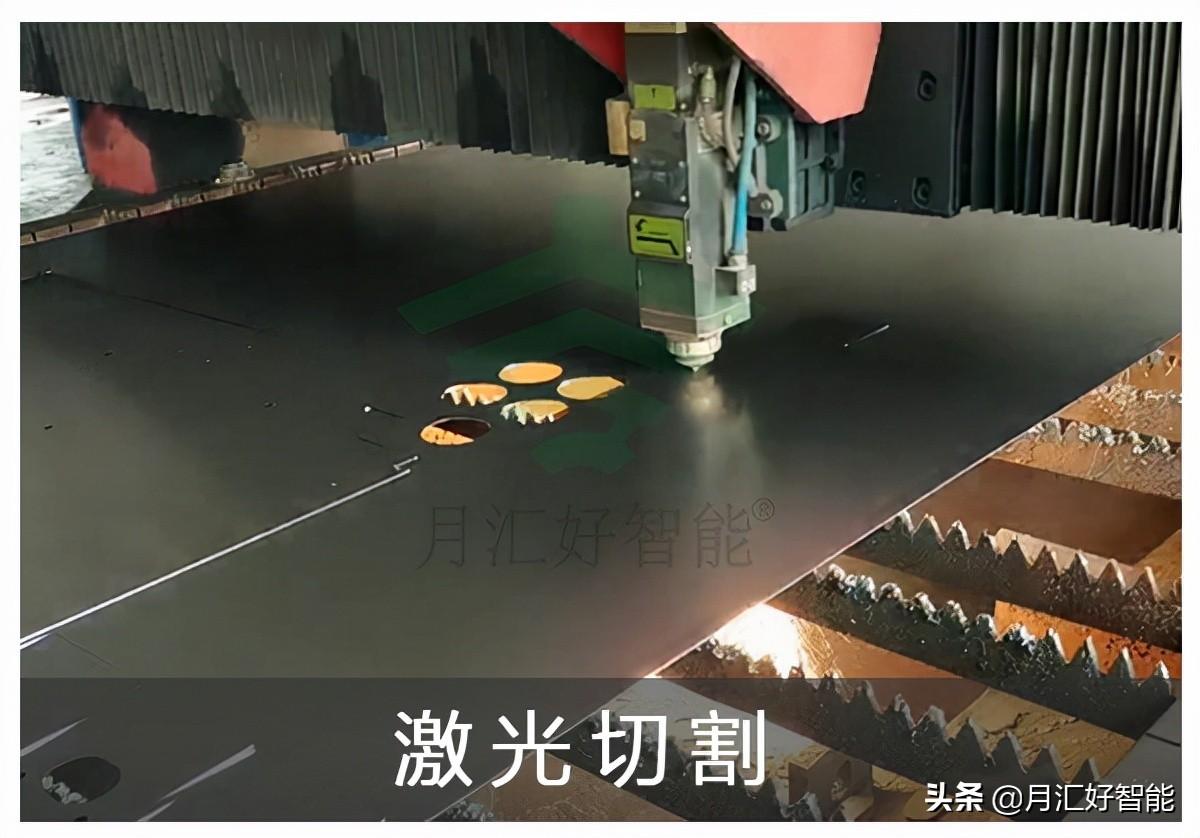

1. Cutting:

There are various cutting methods, which refer to the process of laser cutting, CNC punching, and shearing of workpieces. NC numerical control cutting and laser cutting can be used for processing thick and complex sheet metal parts; Machina succidentia opera cum dimensionibus maioribus secundum longitudinem et latitudinem potest extinguere; Punching machines can be used in batches to process the shape and circular holes of workpieces.

Sheet metal processing laser cutting

2. Reverse in altum

Flanging, also known as hole drawing, refers to the process of forming a circular hole edge on a workpiece using a mold on a regular punch press or other stamping equipment. It is to draw a hole of a specified size on the pre-punched hole, which can make the dents punched by the workpiece stronger. It is generally used on workpieces with a thickness of less than 1.5mm.

Sheet Metal Processing Copper Bar Punching

Sheet Metal Processing Copper Bar Punching

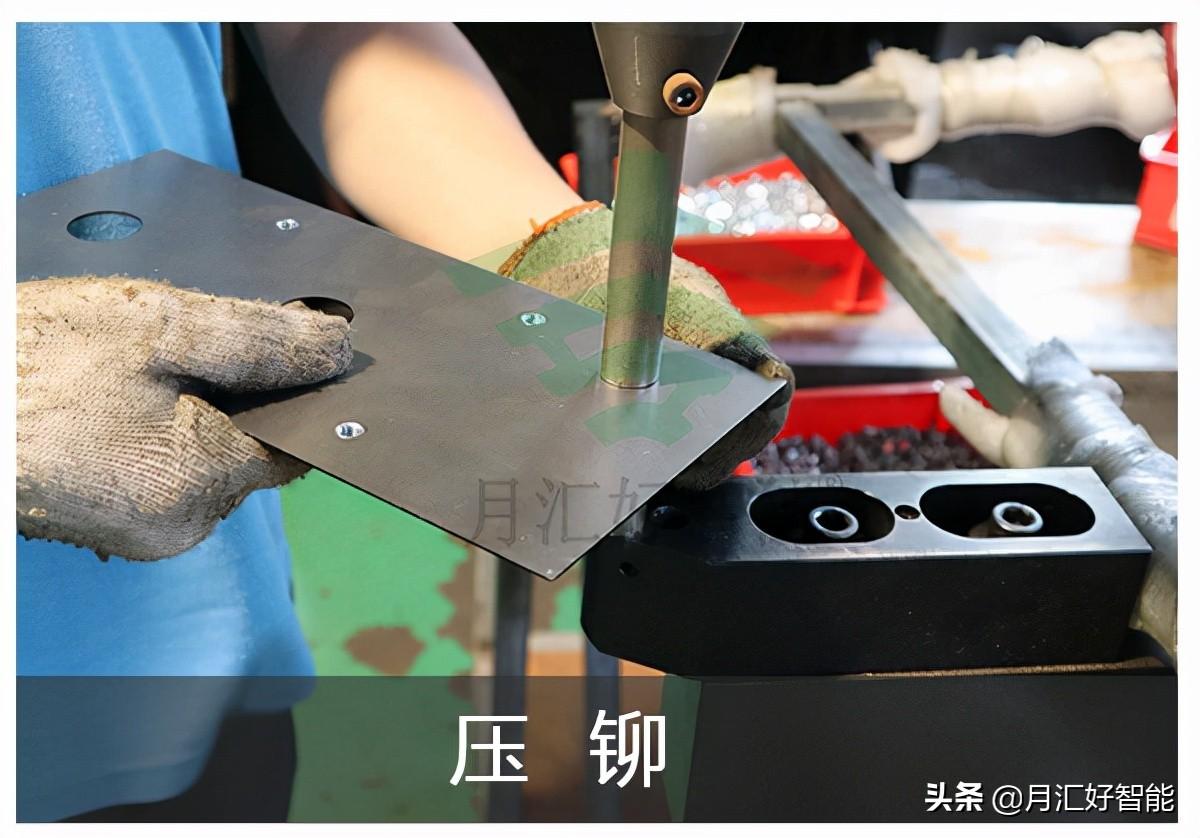

3. Press riveting

Usually refers to the process of firmly riveting and crimping rivet bolts, rivet nuts, rivet screws, etc. on workpieces using punching machines or hydraulic riveting machines.

sheet metal processing riveting

sheet metal processing riveting

4. Bending

Bending is the process of shaping a workpiece from a bending machine using a folding bed and related bending molds, which can enhance the strength of the processed workpiece to a certain extent.

Sheet Metal Processing CNC Bending

Sheet Metal Processing CNC Bending

5. Welding

The common types of welding processing include double shielded welding, argon arc welding, electric welding, robot welding, and butt welding. The process mainly involves welding two or more parts together to achieve the purpose of processing finished products or assembled parts; aut extremi lateribus individuorum opulentur ut extremi anguli pretiosi faciant et multiplicentur fortitudinem colligionis.

Sheet Metal Processing Box Welding

Sheet Metal Processing Box Welding

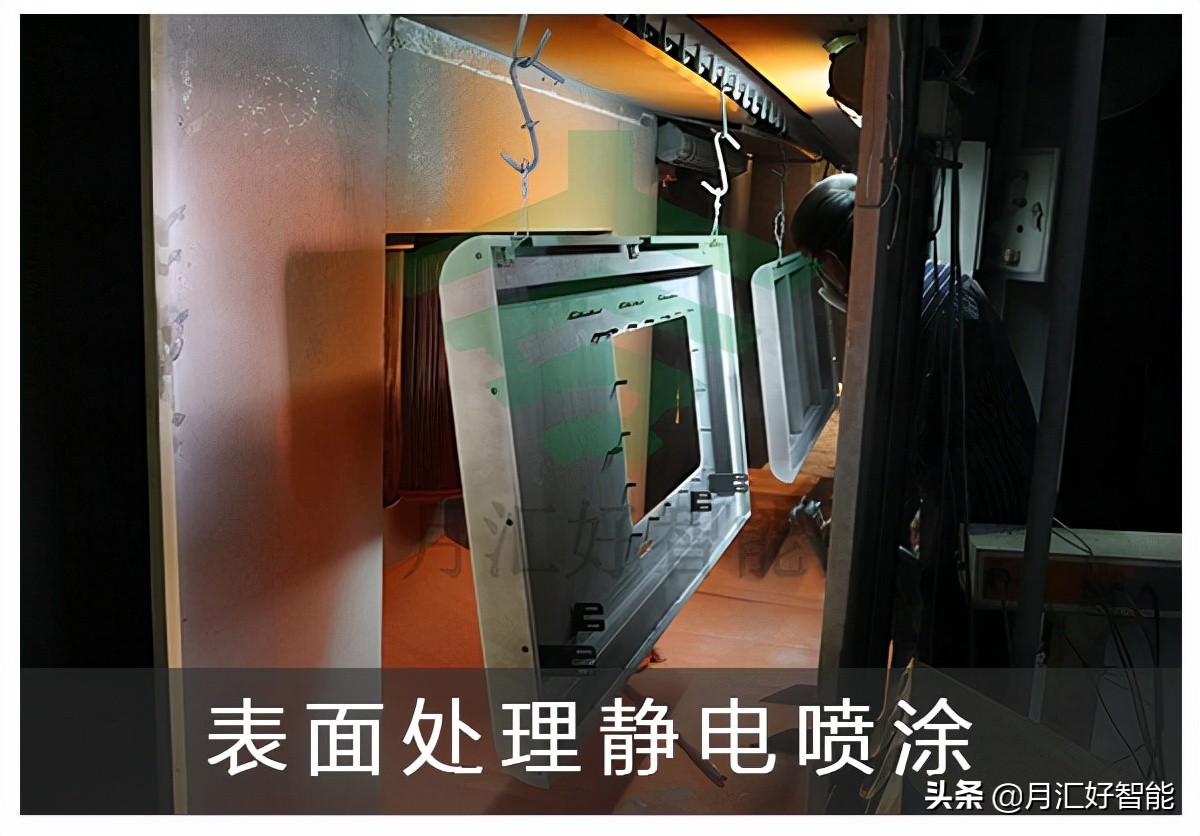

6. Meditate superficie

Medicina superficie includet pulverem phosphationis, cincum multicoloratum, chromatum, pingam baking, oxidationem etc. Post pelliculam phosphationis, pulverem electrostaticam subiectum potest, quod ad folia frigida et galvanizata est adequat. Electroplating zinc multicoloratus generally involves surface treatment of cold rolled sheets and machined parts; Chromatium et oxidationem generale in superficie tratione aluminiorum et aluminiorum profilorum utiliuntur; Surface treatment is to achieve a beautiful appearance and provide protection for sheet metal parts a s a whole. The specific surface treatment method depends on the customer's material requirements

Sheet Metal Processing Cabinet Door Spray Coating

Sheet Metal Processing Cabinet Door Spray Coating

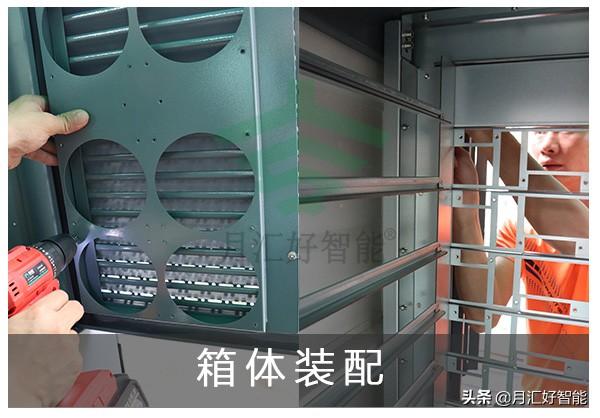

7. Assembly

It is to assemble multiple parts or components according to the requirements of the drawing in a complete workpiece product. The assembled workpiece may be a finished product or a semi-finished product.

Assembly of charging pile corpus for sheet metal processing

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque