Plus et plures partes metallis hodie in diversis aspectis vitae nostrae utili sunt. So what is the general manufacturing process of sheet metal parts? Quomodo id in opus nostro applicamus? Haec articulus haec contentos explorabit.

Multae partes metallis in culina sunt

Generalis loquentibus, fabricatores metallici usus sequuntur sequentes gradus post recipientem formale fabricationes de clientes.

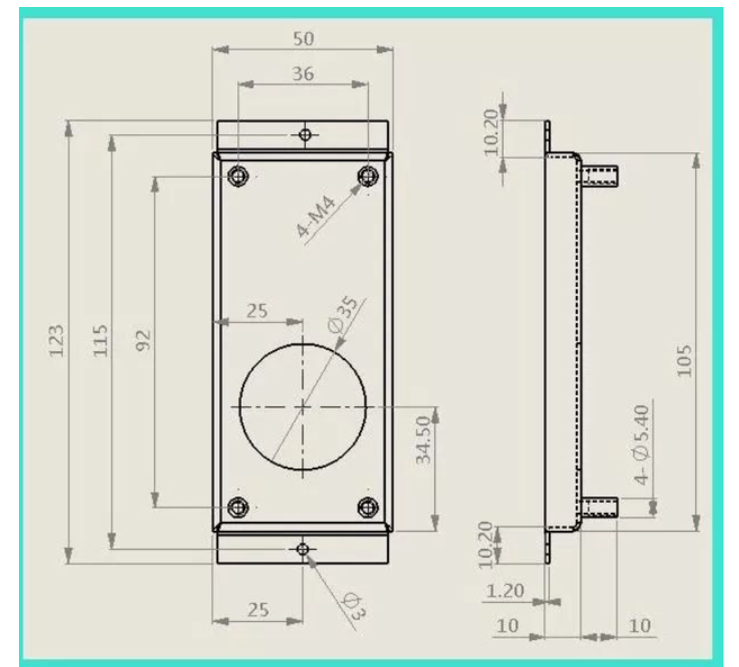

1. Examina diagrammas

Cur fabricatores metallorum lapides similiter duobulum diagrammas quam primum gradus probare debent? This is because many engineers in the customer have not been exposed to the production process of sheet metal parts, and may not be proficient in the production process of sheet metal parts, so there are often details in the drawings drawn. And sheet metal manufacturers are professional and proficient in these, so sheet metal manufacturers will first check the drawings and confirm the finished product dimensions and related requirements with customers. Nunc post clarificationem novissimis necessitatibus clientes poterimus cum scriptura procedentis productionis procedentis.

Sheet Metal Parts Drawing

Sheet Metal Parts Drawing

2. Definite modelum tabulae et confirma datum emissionis

Hoc principium est substantiam confirmare secundum necessitates drawing is artificis, et confirmare quantitatem ordinis tabulae based on the order quantity. Nequaquam si tabula correspondent in stock in fabrica est, necesse est informare clientem temporale. Quia haec directo influent tempore transferentis substantiarum, sublime ad clientes cum urgentibus temporibus transferentibus. Si tempore transferentis non prior communicatum est, multo passiva erit in posteriora scena, et etiam ad infringendum contractum propter propria causam. Hic negativum effectum est ad reputacionem et credibilitatem fabricae. Pro hoc parabolam tabulae et tempus liberationis primus gradus est accipere.

Common cold-rolled sheets, available in coil and flat plate shapes

Common cold-rolled sheets, available in coil and flat plate shapes

3. Manufacturing and processing technology and production process

Haec est locus maximus pro fabricatione metallorum folii. Generally speaking, the production process of sheet metal parts is as follows: 9312Calculatethe unfolded length and confirm the cutting size. 931313; Bending Samsung;Mechanical processing along 931515th;Surface treatment along 931616th;Packaging and shipping.

Calculating the unfolding length is an important aspect, and we need to consider the unfolding coefficients of different materials comprehensively when calculating the unfolding length. Generally speaking, each factory has experience with the unfolding coefficients of commonly used materials, and we can apply them. Si laser cutting est, generale non relinquemus aliquid allowationem. Si cum machina shearing succiderit, debemus reservare processationem allowationem et determinare optimum methodo cutationis, quoniam hoc directe efficit utilizacionem materiae. Metodo bona cutationis totam tabulam quanto possibilis operire cum requiribus tecnologiae processationis component is.

laser cutting material cutting

laser cutting material cutting

Quot 931313;Bending, maquinam bending ad hanc gradum utilimus. Potimus elegere appropriate bending mold secundum opus drawingis. Si universa fermenta fermenta nostra non valebit, oportet nobis facire fermenta fermenta specializata.

Robot operated bending machine

Robot operated bending machine

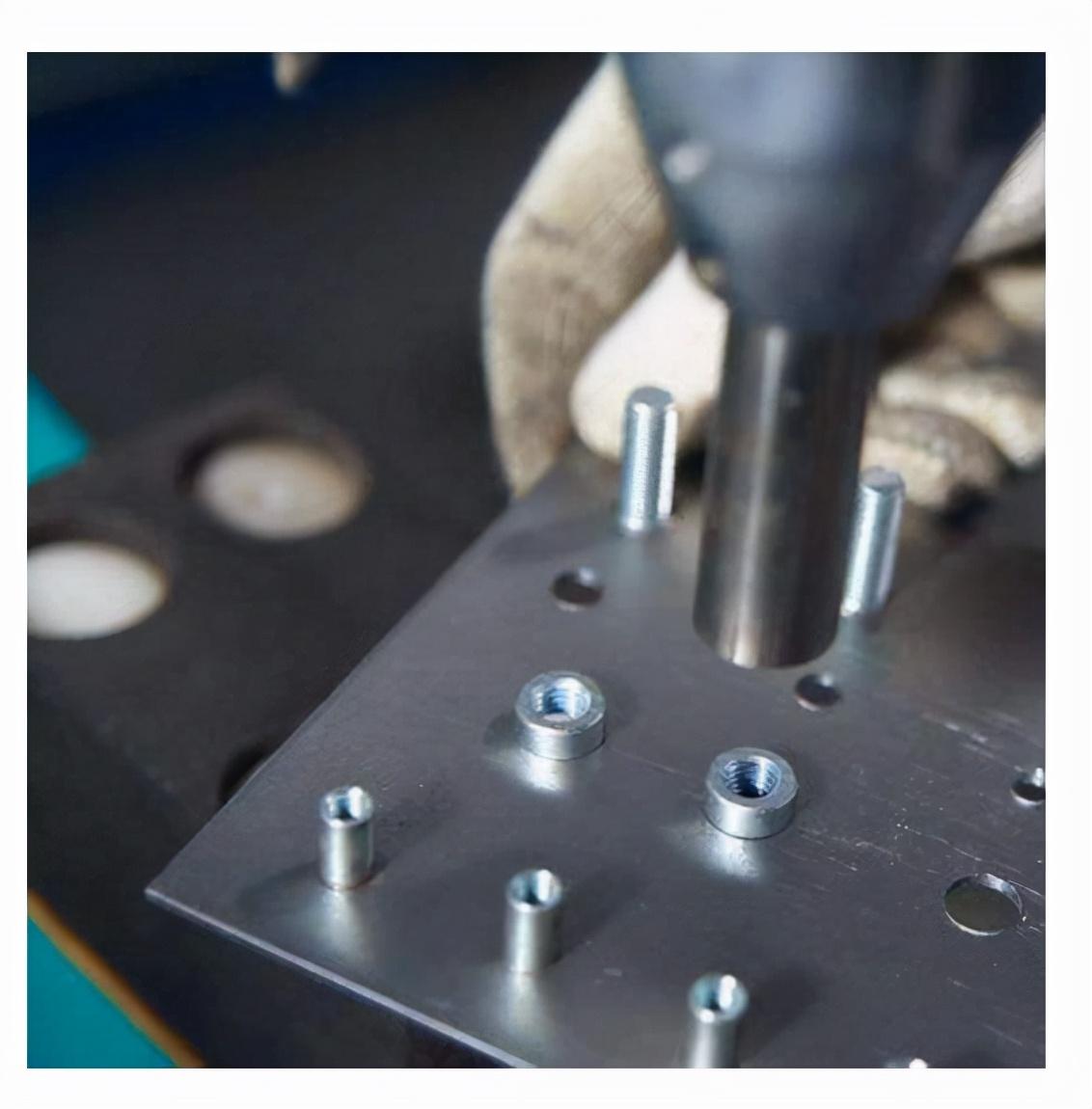

:: 9314; Mechanical processing, the main purpose of which is to process features that cannot be produced by cutting and bending processes. Common processes such as tapping and riveting can only be completed after bending because if these processes are performed before bending, deformation may occur during bending.

riveting process

riveting process

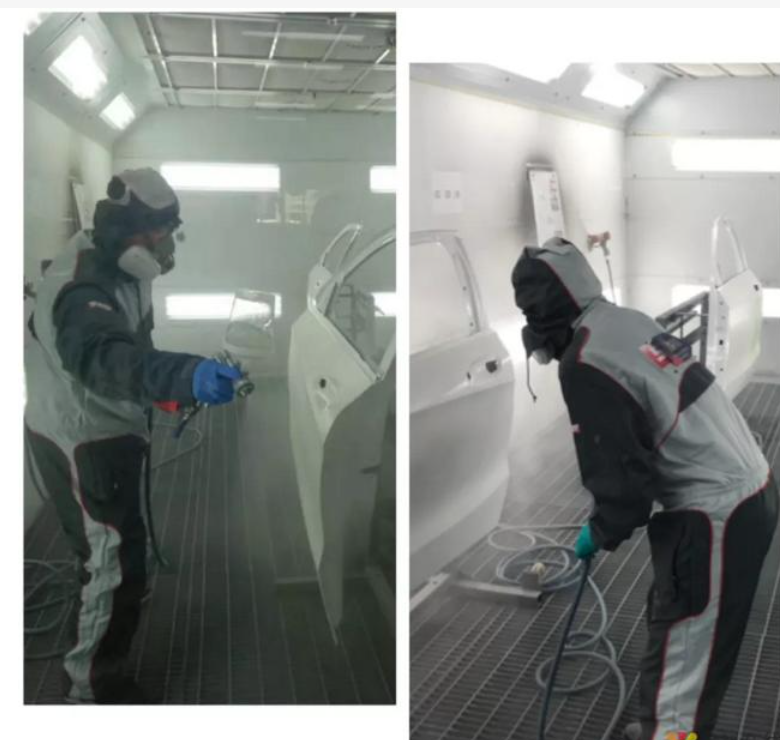

Guid9315; Surface treatment, which is the last set of processes before shipment, mainly involves surface treatment of components according to customer drawing requirements. Common surface treatments include wire drawing, painting, oxidation, etc.

@ 000 Spray Painting Process

:: 9316; After packaging and shipping, we will conduct final measurements and inspections on all finished parts. Hic principium est ad inspectionem qualitatem apparentis. Utrum defectus pinguis sunt, problemas qualitatis superficie etc. Dimensional measurement is also the final verification and inspection. Generally speaking, the previous process is sufficient to ensure the accuracy of the finished product dimensions, and dimensional control is carried out during the process. Si emissio magnitudinis solum ante consilium finem revertitur, error inproperabile est fabricatori metallis lapides, et perditio potest a fabricatore metallis lapides portare.

Post confirmationem non esse problema, possumus procedere packaging et navigare. Haec est processus fabricationis metallis completus folios.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque