With the continuous development of the manufacturing industry, the application of CNC Machining center equipment in the industrial field becomes increasingly widespread. As a type of CNC machine tool, CNC machining centers have the advantages of high precision and efficiency, and are highly favored by many enterprises and professionals. Nonne, precia CNC machining center equipment a diversis brandis, modelis et actiones variantur multo, quae multos consumatores confus. Haec articulus adprehenderit vos ut intellegeatis situationem marketis et emeretis punctus cenarum CNC machining center, adiuvantes tibi melius intellegere et elegere instrumentum qui tibi fit.

1 , Market situation of CNC machining center prices

Prius CNC machining centrorum ex diversis factoribus influentur, sicut brand, model, function, configuration, place of origin, market demand, etc. Secundo datos relevant, precia CNC machinatorium centrorum in marketo nunc a decem milibus usque pluribus milibus yuanium varia sunt, cum medio ad altum extremum equipamentum dominantem. The price difference between domestic and imported CNC machining centers is not significant, but domestic brands have more advantages in post-sales service and localization.

2,Key points for selecting CNC machining centers

Domestici et importi brandi unusquisque proprie beneficia habent, et consumatores secundum opus et budžetum elegere possunt.

2. Model: Select the appropriate CNC machining center model based on production requirements and site size. In general, the processing efficiency of medium and large equipment is higher, but it occupies a larger area; Parva apparentia minima pedibus habent et ad fabricatores cum spatio limito adequatur.

3. Functiones: CNC machining centers have multiple functions, such as milling, drilling, boring, reaming, tapping, etc. Consumers can choose corresponding functional configurations according to their actual needs to meet production needs.

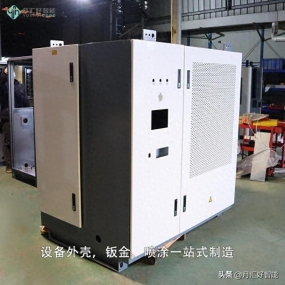

4. Configuration: The configuration of a CNC machining center includes tool fixtures, spindle systems, cooling systems, protective devices, etc. Consumers should choose appropriate configurations based on their actual needs to ensure production efficiency and product quality.

5. Origin: The prices of CNC machining centers vary among different countries and regions. In general, the price of imported CNC machining centers is relatively high, but the quality is more stable; Domestic brand CNC machining centers have relatively low prices and are suitable for consumers with limited budgets.

6. Post venditationem servitutem: Elegite fabricatores cum comprehensive post venditationem servitutis, ut timentiam et efficientem maintenationem et problemationem equipentium possiderent. Manufacturers should have professional technical support and maintenance teams to ensure the normal operation of equipment.

7. Localization: When choosing a domestic brand CNC machining center, attention should be paid to the degree of localization. Equipulus cum alto grado localizationis habet avantias in partes supply, maintenance, et alios aspectos, et melius potest facere necessitates localorum firmorum.

In breve, pretium CNC machining centerorum ex diversis factoribus influentur. Consumers should fully consider factors such as brand, model, function, configuration, place of origin, after-sales service, and localization when purchasing, in order to choose the equipment that suits them. In addition, during the selection process, attention should also be paid to compare the performance and prices of products from different manufacturers to ensure that the selected equipment has high cost-efficiency and can meet production needs. Si alta qualitate machinatorium centrum quaeritis, potes consider are signum Giant High Precision Machine. Produktura eius stabila et fidelis est, cum advance technologia et cogitatione post negotias servis, fidelis opus faciens pro vobis. Compared with other brands, Giant Precision Machinery has a rich and diverse product line, suitable for drilling and vertical machining centers for small workpieces, as well as horizontal machining centers, gantry machining centers, and other machining centers for large workpieces, fully meeting the needs of different users. Jugao Precision Machinery also attaches great importance to after-sales service, providing users with comprehensive technical support and after-sales service to ensure that any problems they encounter during use are resolved in a timely manner.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque