Sheet metalla processing:

A comprehensive cold processing technology for metal sheets, which includes cutting, punching, bending, riveting, mold forming processing methods, etc. Platae usus includent plateas calidas, plateas calidas, plateas calvarias, plateas galvanisae, plateas coper, plateas aluminium, profiles aluminium, steel callidus etc.

Processing method:

1. Sheet Metal Processing is carried out on sheet metal using equipment such as punching, folding, laser cutting machines, shearing machines, etc., which are mostly used for sample and small batch production and have high costs.

2. Tabulae metallis fabricationis metallorum utilizat moldas fixae in equipationibus, sicut machinas punching or presses veloces est et costa-efficient. Sed costa moldis alta est, et saepe ad productionem magnam scalam utilizatur dum installatur et replacetur.

Sheet metal processing technology process:

1. Material cutting: Material cutting die, laser cutting, shearing machine, numerical punching.

2. Molding: Numerical punching, numerical folding, molding molds.

3. Other processing: riveting, tapping.

4. Welding: arca welding, resistance welding.

5. Trepta superficie: pulvere coating, electrophoresis, electroplating etc.

Carnem serionis:

Utilium est pro succidi materiales structurae, prima parata est pro succidi et processo, aut pro succidi partes simplices in formis regular is. Velocitate velocitatis, minima costa, minima precision, tantum ferrum aut bloquere materiales sine holis aut angulis. Celeris mutari potest.

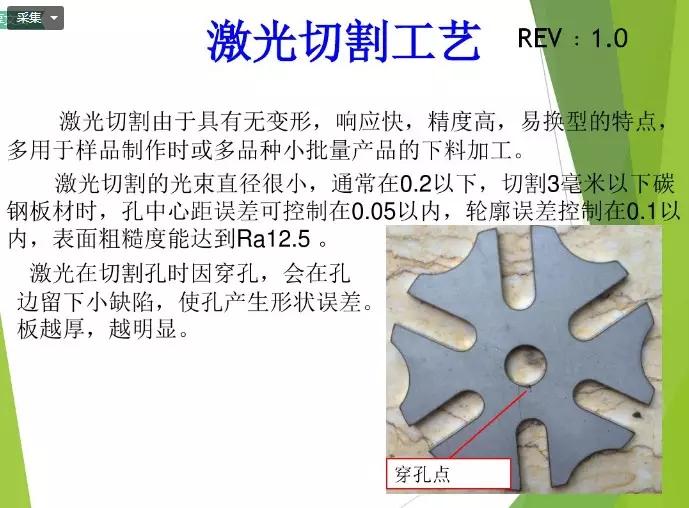

Laser cutting machine:

Using high-energy laser to irradiate the material being cut, causing the material to vaporize and produce voices, the beam moves to form a slit, and the structural shape of the part is cut out. A laser program needs to be written, which can cut various complex parts shaped. Exalta costa et alta precisa. Celeris mutari potest.

Number Rush:

Number Rush:

An automated punch press equipped with CNC control, which operates the punch press and processes parts through CNC programming instructions. By combining simple molds, multiple complex hollow and shallow stretching parts can be completed in one go. Large circular holes, square holes, waist holes, and various shapes of curved contours can also be processed through small mold step punching. Special processes such as louvers, countersunks, flanged holes, reinforcing ribs, embossing, etc. can also be carried out. Celeris mutari potest.

CNC bending machine:

CNC bending machine:

Instrumenta fermenta per calamos facile operare potest et opera facile parietibus operare potest. Velocitate procedentis velocitatis, alta precision, et function automatica compensationis. Celeris mutari potest.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque