Brief introduction and industry overview of sheet metal:

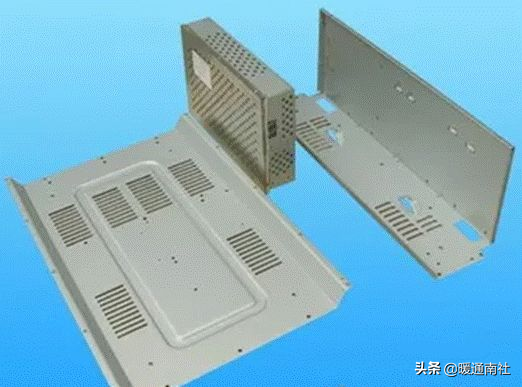

With the development of the automotive, communication, IT and daily hardware manufacturing industries, sheet metal processing has become increasingly popular, and understanding sheet metal processing has become more necessary.

2. Operatio manus aut mechanicalis fabricationis lapides, profiles, et pipes in partes quaecumque formam, granditudinem, et accuractionem calicetur metallis. In ventilatione, conditione ductibus et componentes eorum amplius utilitur.

3. Sheet metal parts are mostly made of metal sheets and pipe fittings. Due to their light weight, high strength and stiffness, shape can be arbitrarily complex, low material consumption, no need for mechanical processing, and smooth surface, they are widely used in daily life and industrial production, such as barrels, basins, ventilation ducts, material conveying pipelines, automotive cover processing, etc. In addition, they can also be applied to external repair work of automobiles.

4. Tabulae metallorum processione normale referunt ad modos, quales tondere, bending, rolling, and flipping formation. Generally speaking, the process of using molds to complete various deformation processes is called sheet Metal Stamping, while the process of manually or mechanically forming sheet metal is called sheet metal processing.

Sheet metal material:

1. Platae electroliticas: SECC (N) (platea resistenta digitorum), SECC (P), DX1, DX2, SECD (platea extensionis). Material hardness: HRB50+-5, tensile plate: HRB32~37

2. Platae frigidae: SPCC, SPCD (platea extensionis), 08F, 20, 25, Q235-A, CRS. Material hardness: HRB50+-5, tensile plate: HRB32~37.

3. Plata Aluminium; AL, AL (1035), AL (6063), AL (5052), etc.

4. Stainless steel plates: SUS, SUS301 (302303304), 2Cr13, 1Cr18Ni9Ti, etc.

5. Other commonly used materials include: pure copper plates (T1, T2), hot-rolled plates, spring steel plates, aluminum zinc plates, aluminum profiles etc.

Sheet metal processing technology:

Teknolojia fabricatione metallorum lapides in basically divisa potest: marking, cutting, folding, rolling (bending), bending, biting or welding, flange making, and flange installation processes. Haec section prima facit proceduras, quales markus, rollus, folding, biting, et bending.

(1) Draw a line

1. Most sheet metal parts are made of flat metal plates, so it is necessary to draw the actual surface dimensions of the sheet metal parts in a flat shape on the metal plate, which is called unfolding drawing.

2. secundum proprietatem dispersionis superficie partium constituentium duae sunt: superficies expandabilis et superficies non expandabilis.

3. Komponentin yüzü tam bir şekilde flat olabilir, çünkü kırıklığına veya kırıklığına uğramadan ve bu tip yüzeyi hareket edebilen bir yüze denir. Aviae, cylindri, et cones superficium deployabilibus sunt. Si superficie partee naturally flatae et expandere non potest super faciem flatae vocatur superficie undetectable, sicut superficie spheris, anulus circularum et superficie helicali, quod solum proximo apertura potest.

(2) - Metodo processi metallis lapides

1. Cut: Cut is the process of cutting materials in the desired shape according to opening. Est multae metodes ad succidendum materiae, quae dividentur in succidendum, punching, et laser succidendum secundum typum et principem operantium instrumenti machinae.

1.1 Cutting - Use a cutting machine to cut the desired shape. Precisio 0,2mm aut supra attingere potest, mainly used for cutting strips or cutting clean materials.

1.2 Punching and cutting - Use a CNC punching machine (NC) or a regular punching machine for cutting. Both cutting methods can achieve an accuracy of more than 0.1mm, but the former has cutting marks and relatively low efficiency during cutting, while the latter has high efficiency but high single cost, making it suitable for large-scale production.

1.2.1 CNC punching machines use upper and lower molds to fix the material during cutting, and the worktable to move to punch and cut the sheet metal, producing the desired shape of the workpiece. In principio duae typi CNC punching machinae sunt: Tailifu et AMADA.

1.2.2 Punch regular press uses the movement of upper and lower molds to punch out the required shape of the material using a dropping die. Ordinary punching machines generally need to be matched with a shearing machine to punch out the required shape, that is, after cutting the strip material with the shearing machine, the punching machine can punch out the required material shape.

1.3 Laser cutting - using laser cutting equipment to continuously cut the sheet metal to obtain the desired shape of the material. Caracterium eius altum precision est et capacitatem partibus cum formis multis complex is procedere, sed pretium processionis relative altus est.

2. Formulatio:

Sheet metal forming is a major processing method in sheet metal processing. Formation can be divided into two types: manual forming and machine forming. Manus formatio saepe utilitur quasi supplementaria processatio aut finitum opus et saepe laboratur. However, when processing some materials with complex shapes or prone to deformation, manual forming is still indispensable. Manus formatio conpleta est per simplices fixturas et jigas. Sequentes metodes prima utiliuntur: bending, eduction, trimming, arching, curling, and shaping.

We discuss mainly machine forming here: bending forming, stamping forming.

2.1 Bending Forming - Fix moldes superiores et inferiores separatis in superioribus et inferioribus lapidibus, utilis servo motores ad transmigrationem et conducendum motum relativum tabularum, et congregate figuras moldis superioris et inferioris ut formatur lapidis metallis. Precisio formantur bending potest 0.1mm attingere.

2.2 Stamping Forming - Using the power generated by the motor driven flywheel to drive the upper mold, combined with the relative shape of the upper and lower molds, the sheet metal is deformed to achieve the processing and forming of the parts. Precisio formationis pulchritudinis superest 0.1mm. Punching machines can be divided into ordinary punching machines and high-speed punching machines.

3. Connection of metal sheets

Ventilationis ducti et componentes ex foliis metallis connectabuntur cum modis, quasi connexio connexio, connexio fluctus, connexio etc. Haec section prima connexiones mordam introducet.

Colligite et mordite extremia duorum partibus metallis (aut utraque lateribus partis materiae) simul et pulsate illos contra invicem stricto. Haec modo connexionis dicitur biting (silva). Sheet metal connection is the process of connecting different parts together in a certain way to obtain the desired product. Connexiones metalla folia divisae sunt in fermentum, fluctum, connexiones ferentes etc.

(1)Bite connection

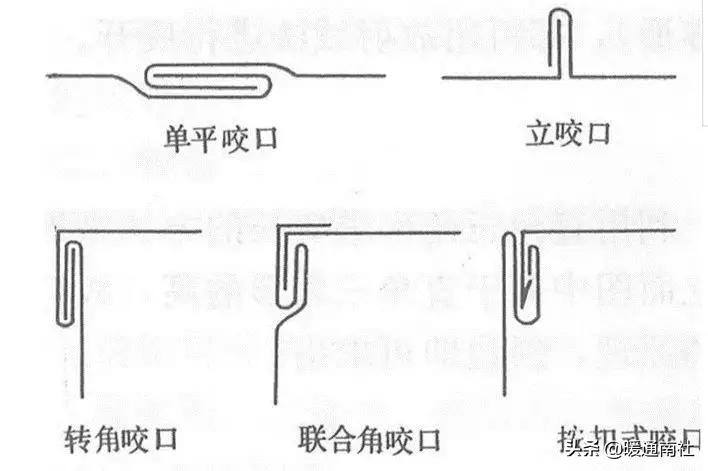

1. Types morum

Cornerum mordum et stilum buckle

2. Application Bite

Variae typi morum in sequentibus regionibus utili sunt:

(1) Singulus mors tabularum tabularum splicientibus, longitudinibus lateribus aut componentibus clausorum utilitur.

(2) Monetas singulae in circularibus, retro et exterior, et horizontale planta ductis aeris utilitur.

(3) Biting cornerum, biting angulos coniunctos, and snapping on biting are used for longitudinal closure joints and rectangular elbows of rectangular ducts or components, as well as corner joints of dentes.

(2) Bite width and allowance

Amplicatio mordis dependit de densitate fittingum piperum, sicut in tabula 8-1 monstrata est.

Dimensio mordis est relatio ad latitudinem mordis, lapides superlapantes, et machinas utilitas.

2. For single flat bite, single vertical bite, and corner bite, the amount left on one board is equal to the bite width, while the amount left on the other board is twice the width of the bite. Therefore, the bite retention is equal to three times the bite width.

3. For joint corner bite, leave the amount equal to the bite width on one board and three times the bite width on the other board, resulting in a total retention of four times the bite width.

4. Utrum lateribus tabulae libere debet.

Bites manum aut mechanicam facere possunt.

1. Manual biting

Processus manus bitationis est sicut:

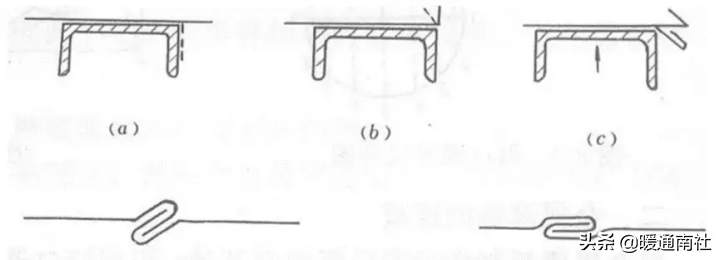

(1) Processus unius mors flati (sicut in figura inferiora monstratus est) involvet plagam cum lineis ante traxeris sinus bending in steelo canali, lineis sinus bending in lateribus steeli canali

(1) Maquinae Bite includent maquinas de mordo linearum et maquinas de mordo elbow, quæ potest morem formare quadraticos, rectangularum, circularum pipes, elbows, dentes et varias diametrarum. Forma mordis accusa est, superficie flata est, granditudo consistente, et productivitate alta est. In processione condicionis aeris et ventilation is ductum amplius utilitur.

(2) Processus mordis formans morsum mechanicam est transire metallum lapidem per plurimas paribus rotatorum cum diversis formis grovae, graduale convertere curvaturam oris folii a parvo usque ad magnum, et graduale formare illum.

(3) When making circular air ducts from sheet metal, it is necessary to roll and bend the sheet metal. Cum ductas rectangulares facientes, quadratum metallicum calciare est.

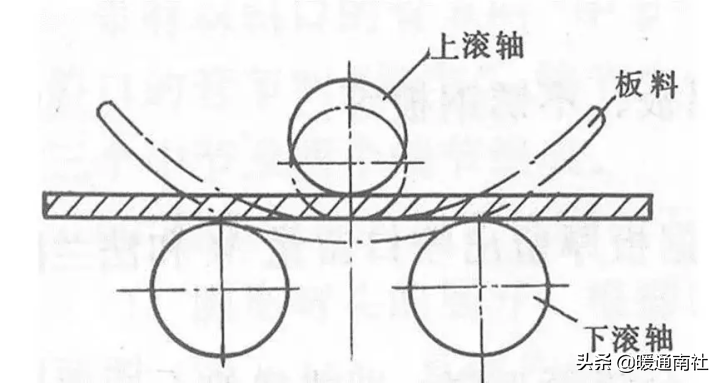

Metodo metalla fermenti per rotantrum rotantrum vocatur rotantur, et cognoscitur quasi rotantur.

1. Principulus basis: Principulus rotationis et bending in figura monstratus est. Metallum lapidem in calculo inferioro positum est, et distancia inter calculos superiores et inferiores adjusta potest. Quando distancia minor est quam densitate metallis lapidis, metallus lapides crescet, quod appellatur compression bending. If continuously rolled, the sheet metal forms a smooth curvature within the range it is rolled to (but the two ends of the sheet metal are still straight due to the inability to roll, and must be eliminated when forming the part). So the essence of rolling is continuous bending.

3.1 Ventura divisa est in: CO2 welding, Ar welding, resistance welding, etc.

3.1.1 Principulo CO2 ferentis: Use protective gas (CO2) to mechanically isolate air and molten metal, preventing oxidation and nitriding of molten metal. It is mainly used for welding iron materials. Characteristics: firm connection and good sealing performance. Disadvantages: easy deformation during welding CO2 welding equipment is mainly divided into robot CO2 welding machines and manual CO2 welding machines.

3.1.

3.1.3 Principle resistentiae benedictionis: Using the resistance heat generated by the current passing through the welding piece, the welding piece is melted and heated to connect the welding pieces The equipment mainly includes the Songxing series, Qilong series, etc.

3.2 Riveting in: pressure riveting connection and rivet connection etc. Equatoria fluentea communa machinas fluentes, arma fluentes, et arma fluentes POP.

3.2.1 Riveting connection is the process of pressing screws and nuts in the workpiece so that they can be connected to other parts through threads.

3

Surface treatment:

The decorative and protective effects of surface treatment on product surfaces are recognized by many industries. In folia metalla industria, superficial treatment methods commonly used include electroplating, spraying, and other surface treatment methods.

1. Electroplatio divisa est in: galvanizing (color zinc, white zinc, blue zinc, black zinc), nickel plating, chrome plating, etc.

Focus principium est protecti layer in superficie materiae formare, quæ actus est protectis et decorativa;

2. Pintura Spray in duas typos divisa est: spray painting and powder spraying. After pre-treatment of the material, the coat is sprayed on the surface of the workpiece with a spray gun and gas, forming a coating on the surface of the workpiece. After dry, it plays a protective role;

Manus fabricata tuba ferata

In non-bending equipment aut in singulis partibus productione minoris partibus numerus bends parvus est, faciens illum non-conomicam fabricare molas bending. In hoc casu, manu bending utilitur. Procedores principes manus bending includent plenum harena, markum, calefactum et bending.

(1) Quando manum pinnas ferentes cum pleno harena, sequentes metodes principales ad prohibere deformationem sectionis pipes steeli sunt: implentem pipem cum fillatoribus (sicut harena quartz, rosinum, et malos punctos conflentem). For larger diameter steel pipes, the sand is generally used. Prius impletionem harena, adhuc unum finem pipe steeli cum conical ligno stoppa. Est foras aeris exterior in ligno stoppa ut permittat aerem intra pipem liber dimittere cum calefactum et expanderet. Post impletionem harena, etiam alteram finem pipei ligno conplere. harena inponeta in tuba steeli munda et arida et firma erit

For steel pipes with larger diameters, when it is inconvenient to use wooden plugs, steel plugs can be used.

(2) Draw a line to determine the heating length of the steel pipe

(3) Calefactio carbo, coke, carbo benzo aut oleo gravis quasi petro. Temperatura calefactionis lenta et uniforme est, et temperatura calefactionis calefactionis fertilis carbon is est generale circa 1050 °C. Ventura frigida in steela sterilis et fuscinis fertilis utilitur.

(4) Pipa calefacta et calefacta in instrumento manu bending potest.

Core bended pipe

Core bent pipe is type of pipe that is bent back along the mold using a core shaft on a pipe bending machine. Functio punctis cordis est proficiscere deformationem intersectionis quando pipa fertur. Formae core shafts include round head, pointed head, spoon shaped, one-way joint, universal joint, and flexible shaft.

Qualitate tubae fusae cordis dependit de forma, dimension, et positio lapidis cordis extendentis in pipem.

Coreless bended pipe

Coreless bending pipe is a method of controlling the deformation of the pipe section of steel using the reverse deformation method on a bending machine. It causes a certain amount of reverse deformation to be applied to the pipe steel before entering the bending deformation zone, so that the outer side of the pipe steel moves outside to offset or reduce the deformation of the pipe section during bending, thereby ensuring the quality of the bent pipe.

Coreless tubas ferentes amplius usatae sunt. When the bending radius of the steel pipe is greater than 1,5 times the diameter of the pipe, coreles bends are generally used. Core bent pipes are only used for steel pipes with larger diameters and thiner wall thicknesses.

In addition, there are methods of bending pipes such as top pressure bending, medium frequency bending, flame bending, and extrusion bending.

Pipa Stella

Duos typos tubarum steelae sunt: tubae steelae et tubae fusae.

(1) Seamless steel pipe

Pipes aeneae sine signa divisae sunt in pipes calide, pipes frigidas trahendas, pipes extruentes etc. Secundo formam intersectionis, duae typi sunt: circulare et irregulari. Pipes sterilis inregulae sunt quadrates, ovali, triangulare, stella formata, etc. Secundo diversis cogitationibus, tenera et tinta cauda sunt, et tinta cauda in partes metallis usus est.

(2) pipe steel welded

Pipa ferrea calefacta et scita quasi pipa ferrea calefacta est in fuscino ferrea et venit in duobus specibus calefacta et non calefacta prior vocatur pipa ferrea alba et novissima appellatur pipa ferrea nigra

The specifications of steel pipes are expressed in metric system as external diameter and wall thickness, and in imperial system as inner diameter (inches).

Metodo magnitudinis markentis pipes steel is est: diameter exterior, murum densitudo, et longitudo, sicut pipe D60106000

Methodus connexionis partibus metallis folii:

Sheet metal parts are composed of many components that must be connected in a certain way to form a complete product. The commonly used connection methods include welding, riveting, threaded connection, and expansion joint. Connexio inter pipes steelis etiam methodos supra referentes adopt. Concerni aquaculum, fluctum et connexiones

Lingua expansionis est metodo connexionis quae deformationem tubarum et tubarum piperum utilizat ad signaculum et fixationem attingere. It can use mechanical, explosive and hydraulic methods to expand the diameter of the steel pipe causing plastic deformation of the steel pipe and elastic deformation of the tube hole wall. Using the rebound of the tube plate hole wall to apply radial pressure to the steel pipe, the joint between the steel pipe and the tube plate has sufficient expansion strength (pulling force), ensuring that the steel pipe will not be pulled out of the tube hole when the joint is working (under force). At the same time, it should also have good sealing strength (pressure resistance) to ensure that the medium inside the equipment will not escape from the joint under working pressure.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque