Precision stainless steel filter screen is a durable filtering metal product widely used in medical, automotive, environmental protection, food, chemical, chemical, mechanical and other fields. Metodo processionis filtratoris precisii sterilis calicis in manufacturo potest aliquid difficile esse. Hic, breve describebimus quomodo proceduram ad processionem filtratoris mesh.

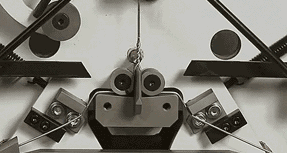

The early processing methods for precision stainless steel filter screens were laser drilling or stamping punching. Laser drilling has the advantage of a low cost, and is almost suitable for all metals. There is no requirement for the hardness of the metal, but scratches may occur on the edges during a laser cutting, and there are some subtle burburs between the apertures. The influence of material thickness on tolerance requires a precision of 0.05%. Stamping punching requires the production of molds, and the cost of a single mold is relatively high. Metals with too high or too low harda sunt.Necessita ad fracturam prona sunt, et anguli similis laser scratchi producent. Haec metoda processionis est valde lentissima in productione massae et solum adequatur ad producendum relative parva quantitatibus produktorum.

Sine duobus modis supra, sunt alii modi processionis? Responsa est yes, qua est ut effectum inter scypicibus criminibus criminibus. Etching potest considere calumnias calumnias cum densitate inter 0.01-2mm, non est necesse facit molas, utili pellicula metalla. Efectum hoc ecclesias calumnias calumnias calumnias calumnias crebratur gratis, non deformatur, calumnus verticatur est, et potest assecurare bonas accuracetas. cum considere processionem calumnias calumnias calumnias calumnias calumnias calumnias calumnias calumnias calumnias calumnias calumnias crebratur.quam 1.5 times thickness, ut dissipatio sculptorum sterilissimi sterilissimi effectionis confortare potest.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque