In general, the Sheet Metal Processing we usually refer to the technology of processing uniformly thick plates without the need for mold forming. The production speed is slow, including cutting, bending, stretching, welding, spraying, assembly, etc., mainly including cutting, punching, folding, welding and bonding processing steps. Procedentia metallorum est ergo tecnologia clara, quam artifices metallorum adprehendere opus est, et est etiam procedus importans ad fabricationem fabricationis metallorum. Scisne quale processus metallis folii est? Below, the editor of Aima Technology Co., Ltd. will introduce you:

Process fabricationis metallis fabricationis est sicut:

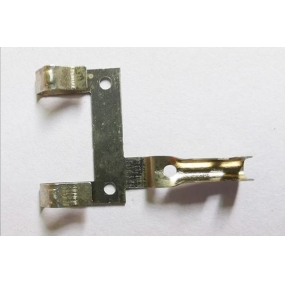

1. Cutting:

Mainly numerical punching and laser cutting. Numerica punching refert to the use of CNC punching machines for processing, with a thickness range of 3mm for cold rolled and hot rolled plates, 4mm for aluminum plates, and 2mm for stainless steel plates. Punching has small size requirements, which are related to the shape of the hole, material properties, and thickness. Laser cutting is a laser flight cutting process, with a processing range of 20mm for cold rolled and hot rolled plates, and 10mm for stainless steel. Avantia eius magna densitate metallis processitus est, velocitas operantis formae velocitatis, et processionis flexibilis.

2. Bending:

Lingua partibus minima radius bending habet. Quando materia bendita, layer exterior extentur et layer interior in area rotunda compressa est. Quando densitudo materiae constantia est, minimus radius interioris inclinabitur, magis gravius extentum et compressionem materiae; Quando fortitudo exterioris in layer superabit limitum materiae, fractura et fractura occurrit.

3. Stretching:

Radius impletae inter fundum partes extensionis et parietem rectum maior est quam densitudo plateae. Profunditudo materiae extentionis in aliquam extensionem mutabit. Profunditudo original is in medio fundi custoditur, materia in fundo impleta tener, materia iuxta flange superiori debilior est, et materia in fillo circum partem rectangularum extentionis in superiora debilior est.

4. Welding:

Mainly for arca welding and gas welding, in which arca welding is flexible, mobile, widely applicable, and can perform all positiones welding; Instrumentum utilitum simplex est, durabile, et humiles constituit. But the labor intensity is high and the quality is not sufficiently stable, depending on the operator's level. Metallum fabricatione lapides est suitabile ad ferendum steelam carbonium, altum ferrum et non ferrous alloys, sicut coper et aluminium cum densitate 3mm aut plus. Temperatura et proprietates flammae fermenti gasolinae poterunt adjusti, et comparati ad arcam ferrum ferrum, aluminum, coper et its alloys, difficiles alloys etc.

5. Spray coating:

Using ovens and other machines to automatically spray oil, powder and other treatments on the surface of hardware components, the product's appearance is made beautiful and attractive, meeting the requirements for packaging and shipping.

6. Inspectio:

The production process of sheet metal processing products is controlled in real-time by the quality inspection department to reduce production losses and defect rates, ensuring production quality.

7. Storage:

Procedentia quae supra proceduras in fabricatione metallorum fecerunt occurrunt requiribus depositae et preparationis ad navigationem, et possunt implaci et depositi.

In summario, it is the manufacturing process of sheet metal processing. Tabulae metalla processione solum simplices fixturas et nulla molda requirit, qui potest effectuale substituere modum processionis molda complex pro punching and cutting, multo breviare ciculum produktionis et reducere produktiones costas. Pro hoc, processione metalla folia in vita nostra cotidiana amplius utilizat.

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole