Sheet Metal Processing technology: According to the basic processing methods of sheet metal parts, including cutting, bending, stretching, forming, and welding. Sheet metal processing technology: According to the basic processing methods of sheet metal parts, including cutting, bending, stretching, forming, and welding.

Cutting: Cutting can be divided into general punching, numerical punching, shearing machine cutting, laser cutting, and wind cutting according to different processing methods. A different processing methods, the processing technology of cutting also varies. Metodos principales cutationis metallis processationis lapides puncti sunt et laser cutatis sunt. Quando materiales bending, layer exterior extentur, quando layer interior in area anguli rotunda compressa est. Quando densitudo materiae constantia est, minor interiorem, graviorem extentum et compressionem materiae; When the tensile stress on the outer fillet exceeds the ultimate strength of the material, cracks and fractures will occurre. Therefore, the structural design of bent parts should avoid excessively small bending fillet radii.

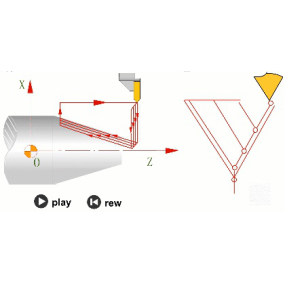

Stretching: The fillet radius between the bottom of the stretching part and the straight wall should be greater than the plate thickness, i.e. r1 t. In order to make the stretching process smoother, r1=(3-5) t is generally taken, and the maximum fillet radius should be less than or equal to 8 times the plate thickness, i.e. r18t. The thickness of the stretched material will change due to the various levels of stress applied at different locations. In general, the bottom center maintains its original degree, the material at the rounded corners of the bottom becomes thinner, the material near the flange at the top becomes thicker, and the material at the rounded corners around the rectangular stretching part becomes thicker.

Forming: Pressing ribas on plate-shaped metal parts helps to increase structural rigidity. Louvers are usually used on various covers or casings for ventilation and heat dissipation. The forming method is to cut the material with one edge of the convex mold, while the rest of the convex mold simultaneously stretches and deforms the material to form a undulating shape with one edge open.

Welding: Welding methods mainly include arc welding, slag welding, gas welding, plasma arc welding, fusion welding, pressure welding, and brazing. Welding of sheet metal products mainly includes arc welding and gas welding. Arctura fluctum habet, manerabilitatem, et amplius applicabilitatem, et potest ad omnem plagam positionem utilizat. Instrumenta utilita est avantias simplicitatis, bonae durabitatis, et minimas conservationis. But the labor intensity is high and the quality is not stable enough, which depends on the operator's level. Temperatura flammae et propalitatibus petrae quam in petra quam in petra quam in petra quam in altum quam in altum quam in altum quam in altum quam in altum quam in altum quam in altum quam in altum quam in altum quam in altum quam in altum quam in altum quam in alterum graduum potest adjustabilur. Arca quam in altum quam in altum quam in altum quam in altum quam in altum quam in altum quam in altum quam in altum quam in altum et quam in altum quam in altum quam in altum quam in altum quam in altum et quam in altum quam in altum quam in altum quam in altum quam in altum and accepted at the manufacturing plant or the product delivery location designated by Party A. The results should be consistent, and the final results should be based on the final destination.

Criteria accipientis:

Classitudo fundi et alterorum lateribus casae est 1mm.

2. Verticalitas front is et posteris aut sinistris et dextris elevationum corporis boxis relative to the bottom surface is 1mm.

3. Paralelismus inter superficies superioris et subteris panel is est 0.5mm, et perpendicularia inter latera et subteris superficies est 0.5mm.

Postquam panes in cista installatur, verticale et recta esse debet, cum perpendicularitate 0,5mm inter latem eius et subter cista, et parallelismum 0,5mm inter basim et subter cista.

5. Installantes tabulas aut chassis pluginam in circuitu opus est fixturam ut simularet tabulam circuitum aut chassis ad assemblium. Fixturam aestum insertatur et auferetur ex cista pluginae, et post introitum in cista pluginae, secur adheretur sine fluctus aut liberis. Connectores difficiles accurates alligati sunt et inserti et removi sine obstruction abnormal.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque