Partibus metalis adflictiones levae ponderis, tenes densitatis, et bonas rigiditates habent. Tolerationes dimensionalis eorum a mollis secutae sunt, et generale non requirant secere mecanicum ante usum. The process and equipment of stamping parts are constantly developing. In addition to the traditional use of press machines and steel molds to manufacture stamping parts, various special stamping forming processes such as hydraulic forming, spinning forming, superplastic forming, explosive forming, electrohydrodynamic forming, and electromagnetic forming are also rapidly developing, raising the level of stamping technology to a new height.

In productione partium stamping metallorum est aliquid detalior scientia et contentio, it a nos debemus discere, intellegere et magistrare illud ut habemus comprehensivum et detaliorem intellectum stamping partes produktionis, et possimus operationes praeceptas bene facire, ut produceremus partes stamping alta qualitate cum excelsis application is exercitus. Nunc produktio partium metallorum in quattuor partes dividere potest:

1. Reasonably and correctly confirm the deformation compensation amount of stamped parts based on the material used and the product structure.

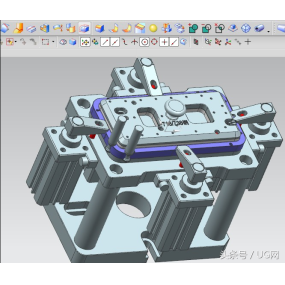

2. Based on the confirmed compensation amount, plan the relevant molds, and then punch out semi-finished or finished products. According to the process requirements, process the semi-finished products into finished products.

4. Further processing of stamped semi-finished or finished products mainly involves checking for any defects or adverse phenomena such as wrinkling, pulling and cracking. Et si densitudo produkti uniforme est, et si effectus fusionis eius superest. Si aliquid problema fuerit, ipsi in tempore sollicitur.

In addition, regarding the tapping and threading processing in the production process of Metal Stamping parts, it mainly involves two aspects: internal threads and external threads. Concernentes virgas internas, est generale necesse diametrum foraminis fundae et machinas exercere super eam. Concerne magnitudinem foraminis fundae, prima determinatum est based on the thread specifications. et ad ligna exteriora ligatur ligno et ligatur morte In addition, during this process, attention should be paid to some detailed issues, such as inconsistent scales and unqualified thread gauge inspections.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque