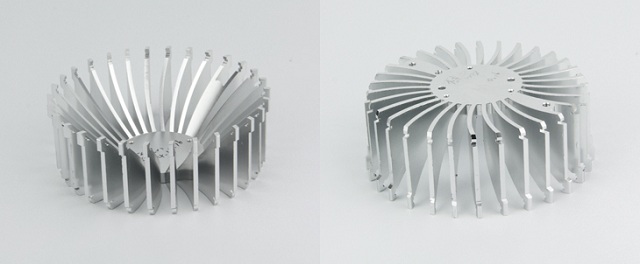

In the CNC Machining industry, everyone will encounter a situation where large quantities of products are produced. To save costs and reduce user expenses, aluminum alloy products are molded and then precision processed. After precision processing, many profiles made of aluminum alloy require further processing, such as wire drawing, anodizing, etc. During processing, it is also easy to cause damage, such as top injuries and scratches. How can we effectively avoid such situations from happening? Shenzhen EMAR Precision Technology, with years of experience in precision machining of aluminum profiles, has compiled and summarized some relevant methods for your reference. Let's take a look together.

1 , Sequentes punctus in productione et processione accipient:

To ensure the quality of aluminum parts and reduce the defect rate, the first step is to implement 5S, especially cleaning. This includes ensuring that molds, workbenches, assembly lines, and packaging materials are free of sharp debris and dirt. Regular and clear cleaning is required, and molds must be cleaned and free of debris;

2. Partibus aluminium calefacti sunt et accumulati simul ut difficiles fierent, ita ut cum succiderit, necesse est aliquid oleum pressionem cruscere super materialem (quod calore dissipat et diligenter materialem) antequam processatur;

3. Si fuerint inventi ardentia significantia in produkto, festina mittere ad molam ad reparationem et sequendum est donec perficiantur resultatio.

4. Putting the flat mold will produce aluminum shavings, so the aluminum shavings under the block must be cleansed every day after production.

5. Produktionibus cum multa numero holarum, necesse est mundare superficiem instrumenti succini aut moli, assecurare quod mold a, succini instrumenti, et produktus semper mundi et liberi debris, redundant superiora damnationem. Si invenerit superiora damnatio, probatio punctus molda aut succindi instrumenti superiora damnationis identificata est et resolveretur ante continuare in productione;

2,Special attention should be paid to the following points in mold or tool manufacturing:

1. Produktionibus cum multo holarum processuri, priorissimus est processi holarum in retro maxime possibilis, etiam si non influent numerum projectorum;

2. Cum profilis aluminium processerint et feramint, cipes aluminium facile generati sunt in fermento, quæ potest causare punctum defectum et indentationem. Materialis aluminium crudelibus PE coactus est. In case of rollers and electroplating, it is better to polish and coat the formed block with hard chromium;

3. Aluminium relativamente soft est et mollus pronus est a material blockage or tool entanglement. Therefore, when designing the gap between the mold and the tool, it is advisable to place a gap of 10% thickness on both sides of the material. A straight depth of 2MM is more suitable for the cutting edge, and a taper of 0.8-1 is appropriate;

4. Pro breviatem materialum aluminium et tendentiam eorum ad fracturam, sublime in reverso colligatione, consilium est non facire trabem pressionem. Etiam si necesse est, trabem amplius et amplius fieri.

5. For precision machined aluminum profiles that require anodizing, if there is a flattening or pushing process of 180 degrees, the product cannot be completely pressed together. Complete pressing will result in acid discharge, and a gap of 0.2-0.3mm should be left to allow the acid solution to flow out smoothly and in a timely manner. Therefore, a limit block must be made in this process and the mold must be calibrated to be higher than the mold;

6. All aluminum cutting edges are required to be cut with slow wire to prevent burrs and uneven material dropping. Aluminum parts are prone to high temperatures, so the hardness of the cutting tools or molds should be above 60, at least SKD11 material should be used, and there should be no inferior materials such as D2;

A nenequaquam, a nequaquam tantum, a nequaquam tantum, nenequaquam tantum, a nequaquam tantum, a nequam tantum, a nequam tantum, a nequaquam tantum, a nequam tantum, a nequam tantum, a nequam tantum, a nequam tantum, a nequam tantum, a nequam tantum, a nequam tantum, nequam tantum, nequaquam tantum, nequam tantum, nequaquam tantum, nequaquam tantum, a nequam tantum, nequaquam tantum, nequaquam tantum, nequam tantum, nequaquam tantum, nequam tantum, anianim tantum anium, nequam tantum, anim tantum opus processi.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque