1. Amanda precisa, potentia, et cost-efficientia

Obviously, the first point in our list is the key we mentioned earlier. Mechanica ad hoc machinam iuravit propter causam, etiam in chaotico. 5-axis machining is the most efficient, accurate and improved in all similar products. Because there are fewer fixtures in multiple operations, using it directly translates to better work piece quality and durability. Hoc significat optima partes, minus deserta, lower item costas, et shorter working hours.

2. Nunc potest creare formas et aspiciones clausas.

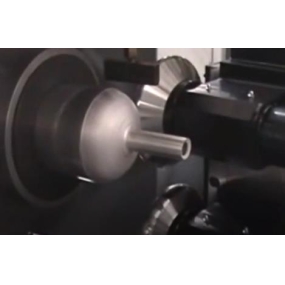

Instrumentum machinae CNC traditionale in tres axis linearum moventur (X, Y, Z). Machina 5-axis in omnibus tres axis linearum et duas extra axis rotationis movet. Compared with traditional 3-axis machining, the ability to accurately move workpieces without removing them has significant advantages.

5-axis CNC machine tools can even reach cluttered viewpoints. Si partes vestrae partes 4D et 5D quaerunt, opus est laboratorio machinarum cum optimis machinarum 5 axis et optimis operatores. Combinabimus clutter cum produktis et serviciis superqualitatis finitibus, quos nunquam cum maquina 2 axis aut 3 axis accipere possumus. Hoc est in singulis constituentibus, ubi omnia in superiora productivitate et superiora qualitate operantium translatur.

3. Able to use shorter cutting tools.

Procedentes subcutores objectos commbersomos potest, sublime quando ad machinas CNC versatiles venerit. Fortunatem, meliora perspektiva utilizati possumus, velocitatem secere, et fortitudinem parterum precisionis, quoniam multo bonum installetur in machinis quinque axis. Hic, caput tuum facientem opus et instrumentum facientem facientem facientem facientem est. Quia machina bene capere instrumentum potest, carga in instrumento redundabitur, tunc redundat misericordiam et oscillationem.

Improving drilling technology with a 4.5 axis machine tool

Using 5-axis CNC Machining and utilizing excellent drilling technology to supply excellent parts. Using our 5-axis machine, we can reach smaller and more cluttered viewpoints. This will result in a cleaner surface of the finished product. Compared to typical 3-axis machines, 5-axis machines can save time and money.

5. Better surface smoothness

Using the rotating fourth and fifth axes, we can bring the parts closer to the tool. Si partes iuxta instrumentum esse possunt, instrumentum breviare potest. Instrumentum curtium cutationis minus susceptibus ad oscillationem in superiora velocitate cutationis, quae directo effecta est gladium superficie. Our 5-axis CNC machining provides a more lubricated surface than the shiny metal bottom of baby robots.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque