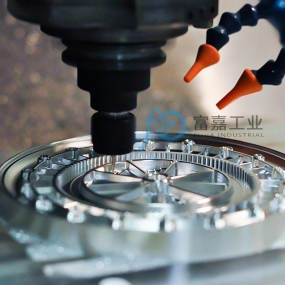

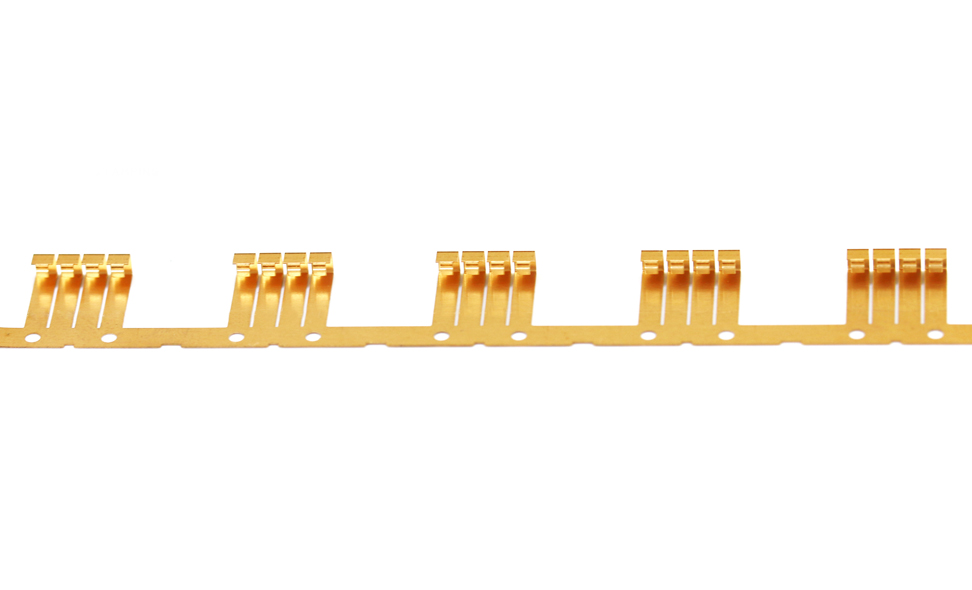

In stamping metallis, punching technology is an important process. Productivitatem et produktum qualitatem effectivam improvere potest. But how to ensure the quality and dimensional accuracy of the parts?

First, we need to perform precise calculations for the cutting process. Haec constituit determinatores, quasi mollus, acutissimum blandem, et densitatem materiae. Nunc per accuratem computationem hoc factorum potest quaestionem qualitatis et dimensionalis precision parterum garantia esse.

Secunda, etiam nobis oportet eligere adequata arma et molda. Equatoria et molda diversa caracteristica et varia varia sunt. Pro hoc, cum opus faceremus, cogitare debemus cogitare cogitare super opus realis productionis.

Finally, we need to pay attention to the operational standards during the production process. Haec operatores sapientiam praecipientiam, equipamentum maintenantiam et uptenantiam, et alios aspectos.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque