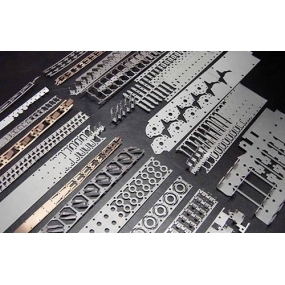

Precision stamping parts, as one of the commonly used components in the field of mechanical manufacturing, have the characteristics of precise structure and high machining accuracy, and are widely used in fields such as automobiles, electronic products, aerospace, etc. However, some problems arise often during use. First, the quality issue of precision stamped parts is the most common problem during use. Unqualified quality can lead to damage to product functionality and even affect the normal operation of the entire production line. Secundo, non sufficient machinae accuracionem parterum precisionis, potest etiam difficiles in ecclesia inducere et vitam servitutis breviatum. In addition, improper use may also cause overall structural damage, thereby affecting the normal operation of the equipment. In addition, improper lubrication of precision stamping parts can easily lead to increased friction, intensified wear, and other problems, affecting the effectiveness of use. Regarding these common issues, we need to pay attention to the following points when using precision stamping parts. First, choose a high-quality supplier of precision stamping parts to ensure reliable product quality; Secondly, attention should be paid to details during use to avoid issues such as insufficient machining accuracy; In addition, lubrication and maintenance work should be done before use to extend the service life of precision stamping parts. Præceptorum est regular inspicere et custodire equipamentum, statim identificare et maniere problemas, et assecurare quia precision stamping partes semper normale operatur in productione. In general, precision stamping parts are indispensable in industrial production, but attention should be paid to solving common problems, ensuring their normal use, and improving product production efficiency and quality.

Salve! Welcome to the EMAR company website!

Latin

Latin » »

» »

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque