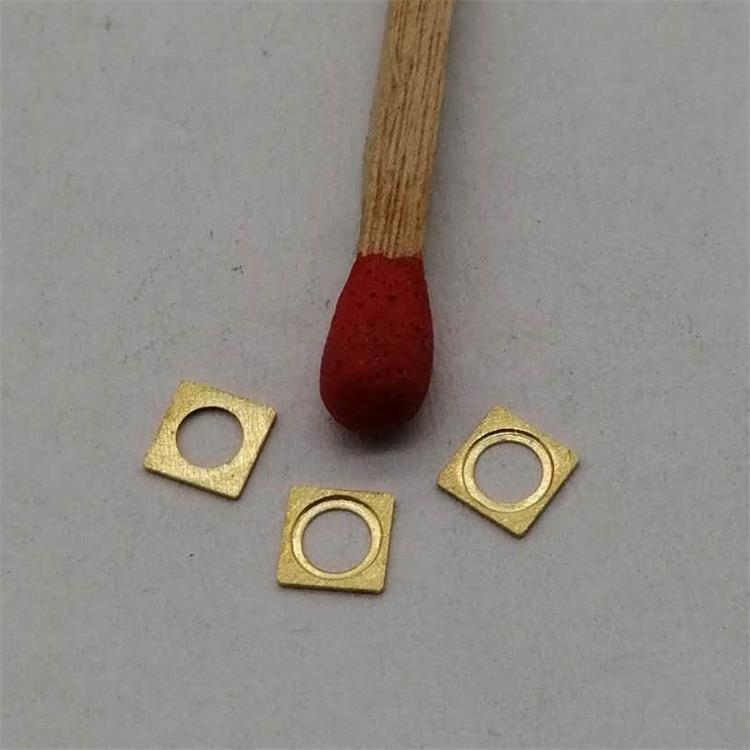

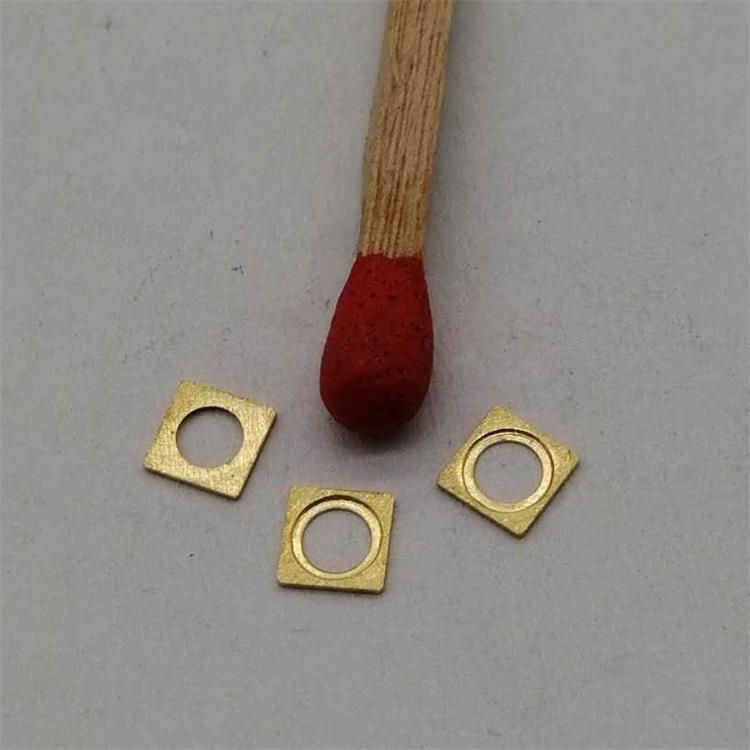

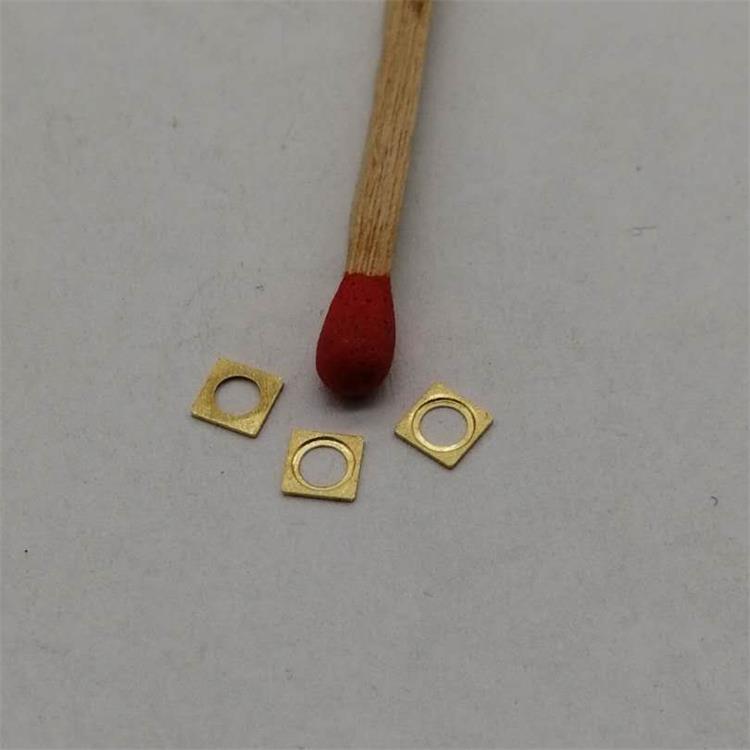

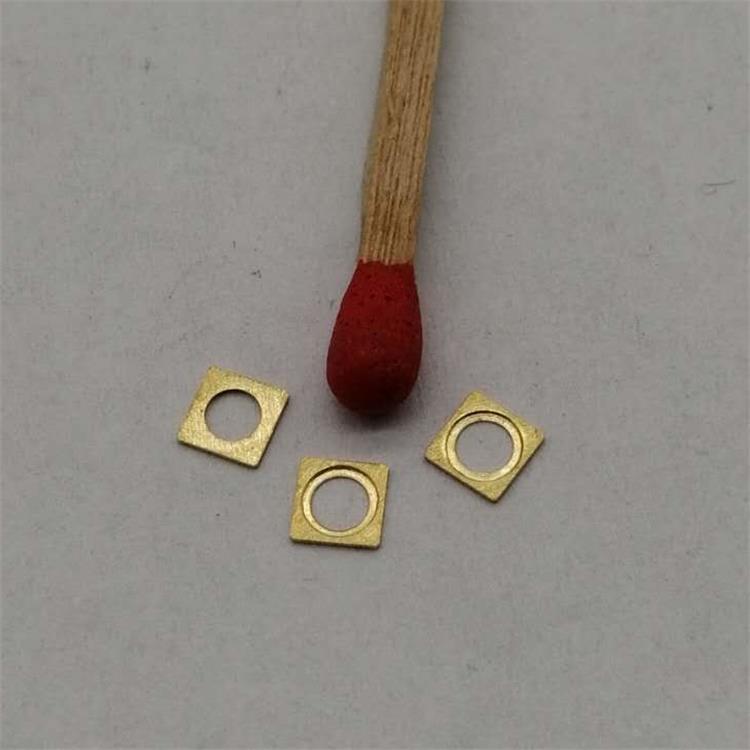

How to create a high-precision IC bracket with a resolution of  ? EMAR Hardware narrat tortuous story of the development of IC bracket production. Cum miniaturatione produktorum electronicorum, crescit interrogatio brachiorum IC, prima a alto precision characterizata (generis tolerans plus aut minus 0,02mm requirant), alta verticalitas, alta planctus et parva ardentia. Initialmente, brachios IC utilizantes machinaturas CNC, sed cum marketum crescebat maior, machinaturas CNC non potuerunt ultra aderire deliverationem et precibus. EMAR Hardware continuously used cold extrusion to produce IC brackets, which fully met the various characteristics of IC brackets, greatly reducing production costs and improving production efficiency, making it possible to mass produce IC brackets on a large scale. Under normal conditions, the daily production of IC brackets can reach more than 150000, almost 100 times faster than CNC Machining speed. The hardest aspect of producing IC brackets through continuous die cold extrusion is the verticality and smooth of the brackets. If the verticality is not handled properly, the lifespan of the punch will be very short, which will also affect production efficiency. The smoothness requires the polishing technology of the fitter. We have hired a Japanese die fitter with 30 years of experience to specialize in polishing volsten steel punches, which has effectively solved this problem. Interested friends are welcome to call me to discuss technology!

? EMAR Hardware narrat tortuous story of the development of IC bracket production. Cum miniaturatione produktorum electronicorum, crescit interrogatio brachiorum IC, prima a alto precision characterizata (generis tolerans plus aut minus 0,02mm requirant), alta verticalitas, alta planctus et parva ardentia. Initialmente, brachios IC utilizantes machinaturas CNC, sed cum marketum crescebat maior, machinaturas CNC non potuerunt ultra aderire deliverationem et precibus. EMAR Hardware continuously used cold extrusion to produce IC brackets, which fully met the various characteristics of IC brackets, greatly reducing production costs and improving production efficiency, making it possible to mass produce IC brackets on a large scale. Under normal conditions, the daily production of IC brackets can reach more than 150000, almost 100 times faster than CNC Machining speed. The hardest aspect of producing IC brackets through continuous die cold extrusion is the verticality and smooth of the brackets. If the verticality is not handled properly, the lifespan of the punch will be very short, which will also affect production efficiency. The smoothness requires the polishing technology of the fitter. We have hired a Japanese die fitter with 30 years of experience to specialize in polishing volsten steel punches, which has effectively solved this problem. Interested friends are welcome to call me to discuss technology!

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque