The common plastic processing techniques we use generally include extrusion, injection molding, molding, blow molding, rolling molding, casting, dipping, and other molding processes, which are selected based on different materials and products. Now let's take a detailed look at these plastic processing methods.

1. Blow molding: Modeles made of HDPE 1/3 or higher can be molded using blow molding. Characteristica indicatorum graduum flammae, sicut conflatile fortitudo, ES-CR, et difficile, similis sunt eis quae ad lapides et thermoformationes utili sunt, sic similis gradus utili potest.

2. Extrusione: Gradibus extrusionis productionis utilis generis habent index meliorum minus quam 1 et medium ad latitudinem MWD. In processo, low MI can achieve suitable melting strength. Wider MWD grades are more suitable for extrusion molding because they have higher production speeds, lower death pressures, and a reduced tendency for melted fracture.

3. Rolling molding: Materials processed using this method are generally broken into powder and melted and flowed during thermal cycling. Roll molding uses two types of PE: universal and crosslinkable. General grade MDPE/HDPE typically has a density range of 0,935 to 0,945g/CC, with a narrow MWD that gives the product high impact and warpage. Its melt index typically ranges from 3 to 8. Higher MI grades are usually not suitable as they do not have the expected impact and environmental stressing cracking resistance of rotational molded products.

4. Injection: Injection is commonly used to manufacture smaller containers for packaging drugs, shampoo, and cosmetics. Una avantia hoc processionis est ut productio botellarum automaticamente exterminat angulos et angulos, sine necessitate post processionis gradibus, sicut usus fluctus. Quamquam alii angusti gradi MWD utili sunt ad meliorem finitum superficie, medium ad wide gradus MWD generis utili sunt.

5. Blowing film: PE film processing generally uses normal blowing film processing or flat extrusion processing method. Most PE is used for thin films, and general-purpose low-density PE or linear low-density PE can be used. Pelliculae HDPE gradus generale in locis qui superiora stretchabilitate et impermeabilitate requirant utilitur.

6. Casting: Casting is commonly used to make plates, electrical insulation equipment, gear, pulleys, decorations and other products. Cast Plastic II vocatur. Mixtura liquid a resinae quae in cavitatem molliam injecta potest aut in cavitatem molliam introducta per alteras metodes ut produktum solidum formam fixum facere sine addendum pressionem aut minorem pressionem habet characteres fluiditates et minimae mensurae mensurae quando plasticae producent.

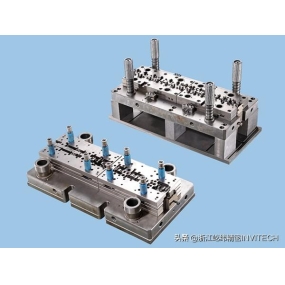

7. Molding: The process of molding plastic materials under pressure, usually with simultaneous heating, using molds or mouth molds. Here, "mold" is used to modify "plastic".

8. Plastic dipping: Plastic dipping is generally used for signage and is a relatively inefficient process. If the temperature is not well controlled, plastic raw materials will be wasted greatly.

The above are the conventional processes for processing plastic products. In fact, with the changing demands of different industries, many CNC plastic processing techniques have emerged.cutores et dentes mittentes calciantes et vasa convertentes

Shenzhen EMAR Precision Technology is a professional manufacturer dedicated to high-precision CNC Machining, including CNC plastic processing. The company has more than 100 CNC machining equipment of various types, which can perform precision machining on various plastics. The products are mainly used in electronic cigarettes, medical equipment, drones, optical parts, etc. Welcome to inquire, visit for guidance, and discuss cooperation.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque