Shenzhen EMAR Precision Technology is a professional manufacturer dedicated to high-precision flange precision parts processing, providing customized and batch manufacturing of flange parts. It is one of the strong precision mechanical processing manufacturers in Shenzhen, commonly known as French flanges, also known as flange flanges or flanges. Flange est komponens qui connectat lapides ad invicem et connectat terminos pipes; Ut etiam flanges ad inportationes et eksportationes apparatus, ut duos apparatus connectantur, sicut flanges de pedibus. Flange connection or flange joint refert to a detachable connection in which a flange, gasket and bolt are connected to each other as a combined sealing structure. Flange Pipeline refert ad flange usam pro piping in installationibus pipeline, et cum in equipationibus utilis, referit ad flange inlettes et exteriores equipentium. In flange cavae sunt et duas flammas coniuncta sunt calves Seallate flanges gasolinibus. Flanges divisae sunt in connexiones triturae (connexiones triturae), flanges ferentes et flanges clampentes. Many flange manufacturers overlook the three important factors of flange solution treatment. Next, EMAR Precision Technology will elaborate on the three elements of flange solution treatment, namely temperature, insulation time, and cooling speed. Let's look together.

1. Elimina laborem difficiliorem ut faciendum faciendum frigidum continuat.

Per sollemnitate solido restituetur lattice twisted, grana elongata et fracta reprimentur, stresso interno eliminetur, fortitudo flange diminuit, et longitudo crescet.

2. Making the flange structure and composition uniform is particularly important for raw materials, as the rolling temperature and cooling rate of each section of hot-rolled wire rod are different, resulting in inconsistent organizational structure.

At high temperature, atomic activity intensifies and dissolves each other, resulting in a more uniform chemical composition. After rapid cooling, a uniform single-phase structure is obtained.

3. Restituere inherentem corrosionem resistentiam flange.

A causa precipitationis carbideorum et latticerum defectum causam frigidae processionis corrosio resistentia steelis stainless diminuit. Post solutionem trationem, corrosio resistentia flange restituetur in optimum state.

Temperatura solution is solida prima per compositionem chemicam determinata est.

Generally speaking, for grades with a wide variety and high content of alloying elements, the solution temperature should be correspondingly increased. Especially for steels with high manganese, molybdenum, nickel and silicon content, the softening effect can only be achieved by increasing the solid solution temperature to fully dissolve them.

But for stabilized steels such as 1Cr18Ni9Ti, when the solution temperature is high, the carbides of the stabilizing elements are fully dissolved in the austenite, and during subsequent cooling, they will precipitate in the form of Cr23C6 at the grain boundaries, causing intergranular corrosion. In order to prevent the decomposition and solid solution of carbides (TiC and Nbc) of stabilizing elements, a lower limit solid solution temperature is generally used.

As the saying goes, flanges are steel that is not easily rusted. In fact, some flanges contain both rust resistance and acid resistance (corrosion resistance). The rust resistance and corrosion resistance of flanges are due to the formation of a chromium rich oxide film (passivation film) on their surface. Resistentia et corrosio resistentia relativa sunt.

Resultas Experimental ostenderunt quod corrosio resistentia steelae proportionalis incrementatur cum incremento saturis chromiae in infirmis mediis, sicut atmosfera, aqua, et medios oxidising, sicut nitric acid Cum contignatus chromium ad quaecum procentum attingerit, corrosio resistentia steeli subito variatur, a facile rustione ad minus rustionem, et a non corrosio resistentia ad corrosionem resistentiam.

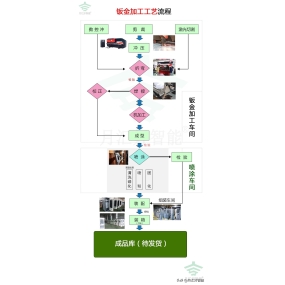

Procedus production is in quattuor typos divisus est: fabricatione, castigo, cuto, et rursum. Some special industries have higher requirements for flange parts, so forging, casting, cutting, and rolling processes cannot meet the needs of users. Therefore, CNC is needed to achieve precision machining. EMAR Precision Technology is a manufacturer of flange precision parts, mainly for precision secondary machining of rough machined flange parts. Our CNC Machining center can process flange parts with a diameter of less than 850. Welcome to inquire.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque