Aluminum alloy parts processing and hardware parts processing are generally carried out through CNC Machining and other methods. However, due to the low entry threshold of CNC machining, there are many small CNC machining workshops in the market, which also cause uncertainty in price and quality. Today, let's take a look at how to grasp the price of hardware parts processing, so that you can find CNC machining manufacturers with quality assurance but not excessively expensive hardware parts

Finding a suitable CNC processing plant

Small factories are suitable for sampling, while large factories are suitable for large quantities. We need to find a suitable CNC machining factory according to our own needs, usual calculated based on the length of the product processing time, and also calculated based on machine tools. For example, if your product can be made using a lathe, but you have to find a machining center to do it, it will definitely be much more expensive. The quotes in the industry are also very different, and they are very mixed. If you want to find a guaranteed one, it is best not to look for a store, but in a store, but in tantum, it is best not to look for a store, but in a store, but in a store, it is in optimum.Quam scio, fabrica quae specializantur in externo processione carissima sunt. Melius est invenire eos qui pro te ipso procedunt sed etiam externo processione, et pretia eorum altissima sunt.

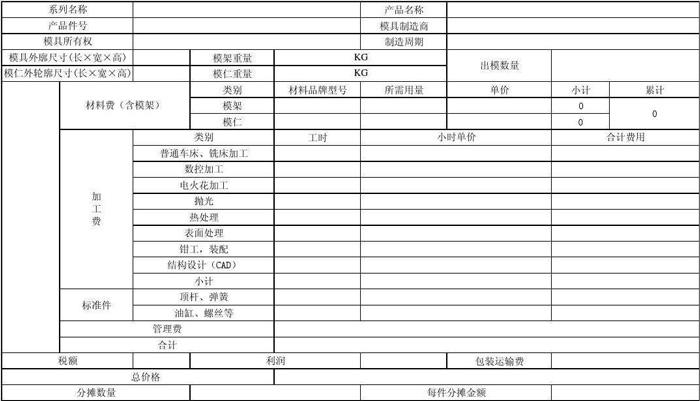

CNC machining quotation

Quomodo pretium parterum hardware procedentium computare

1. Primo, debemus aspicere tibi diagrammas et necessitates technicas

2. Materiales et labores in diversis regionibus variantur, et in aliis locis, differentia pretio significantia est

3. Generally, parts are calculated based on material cost, processing cost, and profit. The processing cost depends on the process, and the price varies depending on the different processing equipment used. Some are calculated based on working hours (such as turning time, grinding time, etc.), while others are calculated based on the process (such as how much it costs to fold a plate into a knife, how much it costs to drill a regular hole, etc.)

4. Est quoque emissio quantitatis. Certe si magna est quantitatis, malitiae erit. Si unus pars est, malitiae erit. Etiam si parvus pars est et materia non vendunt, pretium universae tabuli tui computabitur. For example, you mentioned 0.3, which is not commonly used by manufacturers. If you have only one or two pieces and only one board at a time (such as 1220 * 2440), then your material costs will be wasted.

5. Si problema cum planta processionis solvere potest ex partes planta processionis suis, non est problema. Si planta processionis ipsa habet aliquid proceduras, quae oportet extraducere, pretium quoque consequente crescet. Si iam outsourced estis, significat vos transiere duas outsourcing proceduras! So when looking for a processing factory, you also need to find the right one, find what they can do and what they are good at.

Specific CNC machining price calculation:

CNC lathe processing cost: The standard algorithm is working hours * wages per working hour+fixed expenses that should be shared, such as depreciation expenses. Praesentia generala pro instrumentis machinae CNC 60 yuan per horam est. Instrumenta machinae est circa 1 metro long a et machina vertica regula est. In areas with fewer machines, the price has slightly increased by more than 10 yuan. Certe pretium variat dependent de manu machinae.

Ordinarium anodizationis quasi 10-12 yuan per kg constat. Assemblatio de produkto specific dependit. Normally a quantitate computatur, et quanto per unitatem costat.

Reference quotation for ordinare anodization: 10 yuan per kilogram pro nigro, 8 yuan per kilogram pro albo (argentum), 12 yuan per kilogram pro colore. Vero pro pretio referentiae, subject to the company's quotation.

Emma Technology Co., Ltd. is one of the leading professional manufacturers of precision metal parts in China, established in 2006. It mainly undertakes business such as CNC machining parts, metal stamping parts, and sheet metal processing.

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole