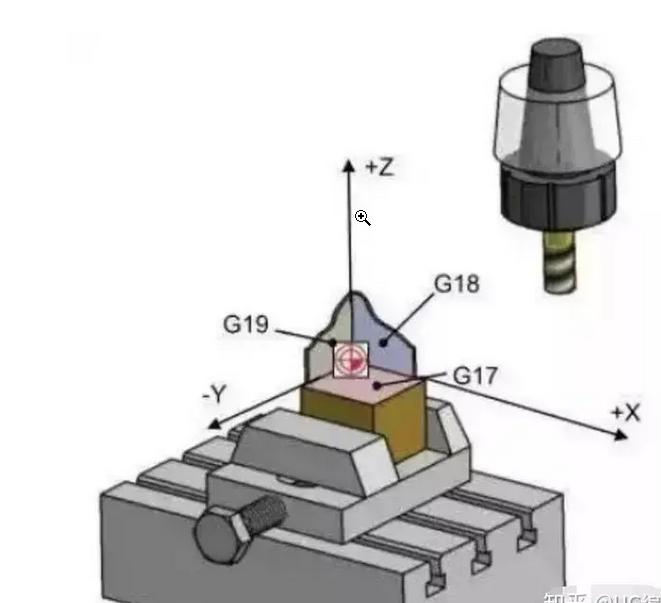

1,Introduction to Programming Methods: A CNC machine tool is a type of machine tool that relies on a digital control system to automatically control mechanical motion and process parts. In CNC machine tools, program instructions are input to enable the machine to perform machining operations on the workpiece. Multae modi sunt ad programmandum instrumentorum machinarum CNC, sed maximus utilis est method triaaxis programmandum. Three axis control refers to the control of the position and shape of the workpiece processed by controlling the three directional movements of the CNC machine bed. Tres axes X, Y et Z respectively sunt. Assis X directo motionis in litore operantis representat, axis Y directos sinistras et dextras, et axis Z directos supra et desuper representat. 2, Instructiones graduum programationis: 1. Operatio Zeroing ante programmationem, opus est operationem nullanum facere, quod significat, ut axis coordinatae instrumenti machinae CNC in statum inicial redit. 2. Usually there are two ways to choose a coordinate system for CNC machines: absolute coordinate system and relative coordinate system. The absolute coordinate system calculates the machining position based on a fixed point on the machine tool workbench as the coordinate origin. The relative coordinate system determines the coordinate origin with the machining starting point as the reference point, and calculates the machining position based on this. 3. Duas metodes interpolationis eligere sunt: interpolatio linearum et interpolatio circularum, quae ad machinandum lineas rectas et curvas, respectively. Interpolatio arcae interpolatio duo directiones sunt: in horologio et in horologio contra horologium. 4. Scribe program based on the machining requirements of the workpiece. Programming should follow the machining principle of fast followed by slow, coarse followed by fine, and small followed by large. 5. Introduce et inite programmam. Introduce scriptum in instrumentum machinae CNC et inite programmam. Nota quia programma praeprocessa est et verificata ante initium.

3,Programmationis precautiones: 1. Introductio programae attention ad corrigentiam formati syntaxis et instruktionibus. 2. When compensating for coordinates and tool length, it is necessary to set them according to the regulations provided by the machine tool manufacturer. 3. For more complex processing, multiple trial cuts are required to determine parameters and compensation values before it can be put into formal production. 4. During the processing, observation should be carried out to adjust the processing parameters in a timely manner. 5. Prius initio programae securitatem et inspectionem accipientur ut securitatem pertinent in processo.

In breve, programmatione machinae CNC est actionem technicam importantiam quam praecepit proficienciam in certe scientia. Praeceptum solum perfectum facit, et praeceptum continuum et summarium experientiae praeceptum magis qualitatis scribere potest. Spero quod supra contentio omnibus adiuvat.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque