Numerical control machining is a high-precision and high-efficiency machining method that is widely used in industrial production. Numerical control machining of parts is carried out automatically by computer controlled machines, which has the advantages of high precision, good repeatability, and fast processing speed. Procedus generalis et gradus specific machinae CNC infra introducetur.

1 , General process of CNC Machining

1. Determine the design requirements, material and process requirements for the processed parts.

2. Scribe numericas controlares, inclusive parametros, quasi vectem instrumentorum, velocitatem et velocitatem fertilium.

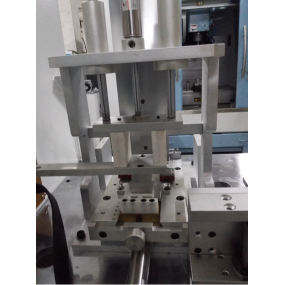

3. Constitue instrumenta machinae et fixturas, et parate instrumenta et opus.

4. Carga programam CNC, defeca instrumentum machinae et proba operationem eius.

5. Procedere facite, monitore processionem, et parametros temporale adjuste.

6. Complete processing, conduct quality inspection, and clean parts.

2,Specific steps of CNC machining

1. Design processing plan: First, it is necessary to determine the design requirements for the processed parts, including size, shape, surface roughness, etc. Scribe numericas controlares secundum propositiones design.

2. Programmas numericas controlarum scribint: Programmas numericas controlarum referunt ad convertendum opus processoris in instruktiones, quas instrumenta machinae per linguas programmationis cognoscere et executare possunt. Programma include parameters such as tool path, cutting speed, feed rate, cutting depth, etc.

3. Instrue instrumenta machinae et fixturas: Selekte instrumenta machinae et fixturas adequata iuxta opus programmae CNC et instale instrumenta et opus.

4. Carga programam CNC: Transfer scriptum programam CNC ad systemam supervisorem instrumentorum machinarum per software CAD/CAM et pone parametros instrumentorum machinarum.

5. Debugging the machine tool: Conduct an idle running test to check whether the various components of the machine are operating normally. If there are any abnormalities, adjust them in a timely manner.

6. Processing: Start actual processing, monitor the processing process, and ensure processing quality.

7. Completio processionis: Post processionem completum, qualitatem inspectionem effectum est ut dimensiones, qualitatem superficie, parallelismum et alteros indicatores parterum inspectionem effectum est.

8. Partes purificationis: munda partes processas ut auferat cipes et stainas olei.

In breve, CNC machining is a high-tech processing method that requires a certain level of CNC programming and machine tools operation skills. Through scientific processing techniques and strict operating procedures, the quality and efficiency of CNC machining can be ensured. Spero quod supra contentio utile esse tibi.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque