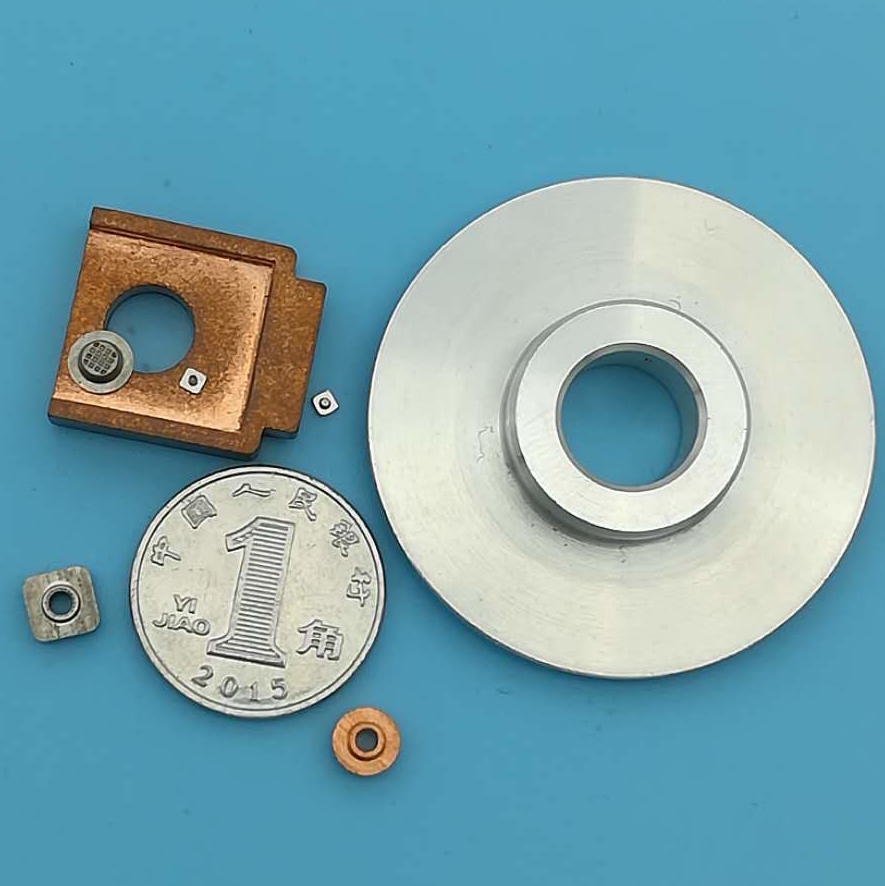

Quid frigidus fraudus est? Termis generis protractionis metallis plasticae. Many customers, when searching online, are unaware of the production process of the product. For example, when looking for parts processed by "cold forging, cold extrusion, cold heading and cold forging" production processes, they search for "stamping parts" online but cannot find their ideal parts. Therefore, I will explain these metal processing processes to everyone here for easy of searching online. Generally, stamped parts are made of metal sheets or strips, and can be molded in various shapes through molds. The molds are relatively simple, and the products can be opened in flat shapes such as computer cases that we usually see. This is the characteristic of stamped parts Audacia frigida, extrusione frigida, capita frigida et frigida fabricatione habent diversa nomines, sed omnes narrant historiam de secendi metallum plasticum in vacuum in temperatura crystallizationis et extruxerunt eas in desideratum formam per moldas, sicut ruinas, sleeves, screws, etc. Est etiam tecnica processionis quae dicitur stretching, est processus elongationis lapides metallos in formam desideratum per molas, sicut fialae calices et ceteris objecti, quæ usus videntur. Metal Stamping, cold forging, and stretching are the three most effective methods for processing metal products, with high production efficiency and large production volume, and play a very important role in the manufacturing industry. EMAR Hardware Co., Ltd. specializes in the processing technology of cold forging, cold extrusion, cold heading and cold forging of micro parts. Through continuous technological progress, the daily output of single mode has reached 200000 pieces, with a precision of 0.02mm. Friends are welcome to communicate!

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque