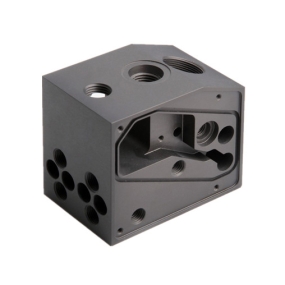

Processing of optical communication components requires very strict dimensional accuracy to ensure that the components can be assembled correctly and meet the high-performance requirements of optical communication systems. Specifically, these requirements can be summarized as follows: 1. Processing accuracy at the micrometer or even nanometer level. The dimensional accuracy of optical communication components usually needs to reach the micrometer or even nanometer level. This high-precision requirement is to ensure that the components can be accurately aligned, connected, and transmit optical signals in the optical communication system. Exemplo, apertura connectorum opticae fibrerum tantum paucos micrometros potest esse, et praecepta ad precision processionis eorum maiores sunt ut transmigrationem opticae opticae efficientem et perditum esse. In order to achieve such high processing accuracy, high-precision measuring equipment is required for inspection during the processing of optical communication parts. Haec apparentia potest precise mensurare parametros, sicut granditudo, forma, et positio parterum, assecurare ut confiteantur requies design. Common high-precision measuring equipment includes coordinate measuring machines, laser interferometers, etc. 3 , Numerical control programming and precise control of numerical control machines are key to achieving high-precision machining in the processing of optical communication parts. Numerical control programming requires determining the optimal machining path, cutting parameters, etc. based on the shape, size, material and other characteristics of the parts to ensure machining accuracy. Numerical control machine tools achieve precise control of the machining process through high-precision servo and control systems, ensuring that the dimensional accuracy of the parts meets the design requirements. 4,The selection and evaluation of cutting tools directly affect the machining accuracy in terms of their quality and performance. In processione componentium communication is opticae, opus est eligere instrumentos succidentes et integro considerare factores, quales materia, forma et granditudo componentium. At the same time, it is necessary to carefully evaluate the tool life to prevent a decrease in machining accuracy caused by rapid tool wear. 5, / Strict control during the machining process requires strict control of various factors such as cutting force, cutting temperature, machine tool vibration, etc., to avoid their impact on machining accuracy. In addition, it is necessary to strictly monitor and inspect each link in the machining process to ensure that the dimensional accuracy of the parts meets the design requirements. 6, Casus opticae connectorum opticae in exemplum adprehendit, quæ effusionem micro holarum per diameter 0,12mm solum et requirementem tolerantiae 0,005mm requirit. Haec machina precision alta necessita est utilizae machinae altae precision, sicut militiae altae frequentiae, et per precisum programationem CNC et controlum instrumentorum machinae.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque