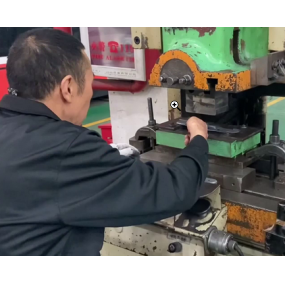

Hardware stamping parts processing factory, processing various Metal Stamping parts, stainless steel stamping parts, irregular parts, etc. Sometimes, when feeding molds during stamping parts processing, it is not smooth. What is the reason for this? Aspicamus subter.

Reages for the unsmooth feeding are:

1. Fulus non potest propter ordinem esse, resultans in virga material, pastor, et mollus non est in eadem lineam rectam.

2. Uneven material strip;

3. Fula non dissolvit, resultat in pauperem pascendum.

4. Positioning too tight;  5. The guide pin is too tight or the straight wall position is too long;

5. The guide pin is too tight or the straight wall position is too long;

6. Poor or too long fixation of the punch and drought of the material strip;

7. Pena superiora brevis est, et virga materiae et fabrica sicca sunt.

8. Posicio impropera blocis fluentes;

9. Insufficient evacuatio potest causare interfectionem.

Haec causa potest omnes pauperem pascere molae, ita est importante regulare inspicere et sustinere molam.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque