Numerical control milling is a precision machining method controlled by computers, mainly used for processing materials such as metals, plastics, and wood. The process and technology of CNC milling involve multiple aspects of knowledge, including CNC programming, operation and maintenance of CNC milling machines, tool selection, and cutting parameters. Sequentes introducet detaljam procedenti et tecnologiae militiae CNC.

1. Programmatio numerica Control

Programma CNC est corda militiae CNC, quae ex serie instruktionum utilis ad controllum machinae CNC militiae machinae ad operationes machinae. Programmas CNC scriptionis magistra linguarum CNC quasi Codice G, Codice M, etc., et scientiam formae, dimensionis, et necessitatibus superficiis operantis. Cum numericas controlares scribent, necesse est considerare parametros, quasi vectem instrumentorum, profunditatem secendi, et fertilitatem ad efficientem et accuratem machinam.

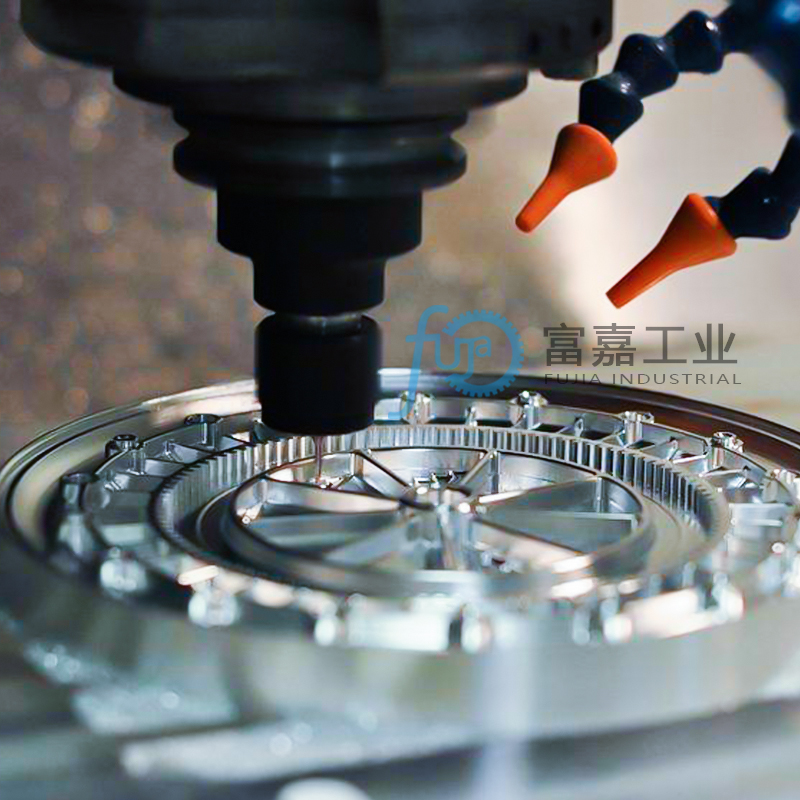

2. Operation and maintenance of CNC milling machines

Maquina CNC milling est instrumentum ad processionem CNC milling utilizatum. Operatores structuram et principibus militiarum CNC intellegere debent et modos operantium suorum magistrare debent. When operating a CNC milling machine, it is necessary to set the machining parameters to ensure machining quality and efficiency. In addition, regular maintenance and upkeep of CNC milling machines are also very important, which can extend the service life of the equipment and ensure normal production.

3. Tool selection and cutting parameters

Instrumentum secendi sunt unum de factoribus claris in milling CNC, et seleccio instrumentorum secendi directo effectivitatem machinae et qualitatem influent. Elegite appropriate tool type and material based on the hardness, viscosity, and surface requirements of the processing material. At the same time, the cutting parameters of the tool, such as feed rate, rotational speed, cutting depth, etc., also need to be adjusted according to specific situations to ensure the service life and machining quality of the tool during the machining process.

4. Optimization of processing technology

For the processing of complex components, it is necessary to optimize the processing technology to improve processing efficiency and reduce costs. Optimizing the machining path, selecting appropriate cutting tools and cutting parameters, machining time and tool wear can be reduced, and machining accuracy and surface quality can be improved. At the same time, the processing technology can be optimized through methods such as process simulation and experimental verification to ensure the stability and consistency of the processing process.

5. Qualitates control and testing

In processo CNC milling, necesse est conducere et inspicere qualitatem parterum machinarum ut certem quod accuractia dimensionala et qualitatem superficiis parterum qualitatem requirentur. Processing parts can be inspected using equipment such as coordinate measuring machines and optical microscopes to promptly detect and correct problems during processing, thereby improving the reliability and stability of the parts. In addition, a comprehensive quality management system can be established to monitor various indicators during the processing and achieve an increase in the qualified product rate.

In summary, the process and technology of CNC milling involve aspects such as CNC programming, operation and maintenance of CNC milling machines, tool selection and cutting parameters, optimization of machining processes, and quality control and testing. Only by considering these factors comprehensively can efficient and precise CNC milling be achieved to meet the processing needs of different fields. Spero quod supra contentio utile sit tibi.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque