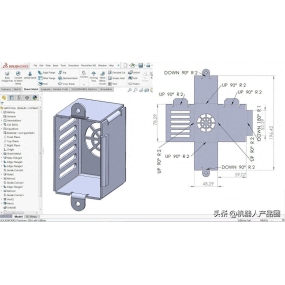

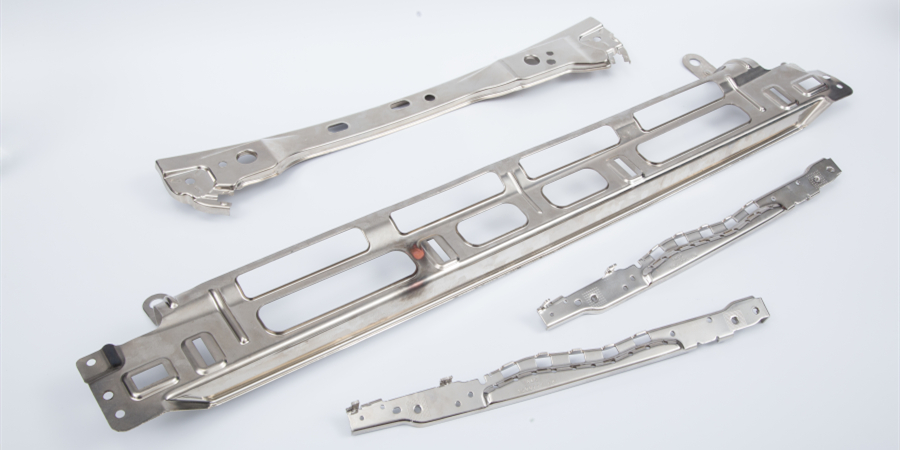

Partes processentes fabricatores, partibus metallicis stampingos, partibus stainless steel stampingos, partibus formatus, etc. Con developmento societatis, professio mold a velociter develovit et in diversis industriis potest esse usata. Installatio et disassembly moldovum etiam quam ordinem requirit. Infra est breve intellegentia ordine dissemblantis partium stampingorum metallicorum moldovum:

1. Quadrata stampio metallo moritur super mensam fixeris, et utraque manus ut tenet parvum moritur iuxta pulverem testamenti superioris, tunc leva illum in fortitudinem ut separaret molas superiores et inferiores. Si non potest separare, unus homo potest levare totam mollam paululum a facie scriptoris et suspendere illum, dum altera persona potest virgam coprinum ut circum materiam templi in unum vadere ut eam separaret. Nota quoniam fuscinulam superiorem post separationem plagam in latere ut non percutiat extremum fuscinulae

2. Clamp superficiem molam horizontal in visum (nota quod tantum pars templi clampere potest), use hex wrench to unscrew the fastening screws of the mold handle, concave mold fixing plate, and concave film at once, and then punch out the pin. Partem superiorem conflationem in partes mortuorum dissipabitur

3. The disassembly of the lower mold is basically the same as that of the upper mold. Remove the elastic unloading plates screws (insert an Allen wrench from the lower cheek direction of the lower mold), remove the unloading rubber, and then remove the screws and pins of the convex and concave molds. In this point, the disassembly of the lower mold is completed;

4. Measure mensuras exteriores, includientes convex et concave molas cum caliper vernier, et recordate eas.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque