Partibus metalis per stampionis mollis processuntur, et sunt multi typi stampionis mollium, inclusive "mollium compositorum". Mollium compositorum sunt mollium multi procedentibus stampionis. Aspicamus characteres processi mollium compositorum:

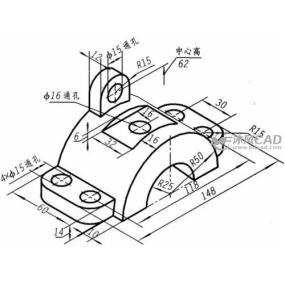

Composita moritur pro partibus stampionis metallorum est multi procedus stampionis moritur qui multi proceduras separatis simul in eadem partem mortis inter unum operationem pressionis. Difficile design pelliculae compositis est quomodo rationale plures convex et concave moritur in eadem direction operation is. Its main structural feature is a convex concave die that serves as a feeding convex die and a punching concave die. According to the different equipment orientations of the composite mold operation parts, it is divided into two types: "positive fitting mold" and "inverted composite mold".

Formal composite mold (also known as sequential composite mold), during the operation of the formal fitting mold, the sheet metal is separated in a compressed state, and the flatness of the Metal Stamping parts punched out is relatively high. However, due to the effectiveness of the ejector and the pressure unloading equipment, the separated metal stamping parts are easily embedded in the edge material, which affects the operation and productivity. The  inverted composite mold usually uses rigid pushing equipment to push down the metal stamping parts stuck in the concave mold. The inverted composite mold with rigid pushing parts is used, and the sheet metal is not punched in a compressed state, so the flatness is not high. Haec structura est adequa ad punctionem metallis caliginis caliginis cum densitate maior quam 0,3mm. If elastic elements are installed in the upper mold, i.e. elastic pushing equipment is selected, it can be used for punching metal stamping parts with soft raw materials or sheet thickness less than 0.3mm and high flatness requirements.

inverted composite mold usually uses rigid pushing equipment to push down the metal stamping parts stuck in the concave mold. The inverted composite mold with rigid pushing parts is used, and the sheet metal is not punched in a compressed state, so the flatness is not high. Haec structura est adequa ad punctionem metallis caliginis caliginis cum densitate maior quam 0,3mm. If elastic elements are installed in the upper mold, i.e. elastic pushing equipment is selected, it can be used for punching metal stamping parts with soft raw materials or sheet thickness less than 0.3mm and high flatness requirements.

Ex analisi structurae pelliculae compositis et formal is et invertis stilis, videre potest ut unusquisque habet proprias avantias et defectus. Formalis stilus est magis suitius pro punching parts with softer raw materials or thinner sheets that require higher flatness, as well as punching parts with smaller hole edge spacing. Fascinae composite inverti non sunt adequa pro puncti partibus punctis cum parvo spatio inter angulos cavorum. Sed, structura conflationis invertis simpla est, et directo utilizat virga arma press ut pulserant partes. Reloasione est fidelis, facile operari, et conditiones favoritas pro mechanizatione partium stampionis metallorum provident. Stoga, amplius utiliuntur.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque