Characteristics and application analysis of laser cutting in Shenyang.

The concept of stimulated light radiation proposed by Einstein in the 1920s foresaw the emergence of lasers. In 1960, American scientist Meiman successfully developed a ruby laser, marking the official birth of lasers. Subsequently, laser technology developed rapidly. After solid-state lasers, gas lasers, chemical lasers, dye lasers, atomic lasers, ion lasers, semiconductor lasers, X-ray lasers, and fiber lasers have successively emerged, and their application fields have also expanded to electronics, light industry, packaging, gifts, small hardware industry, medical equipment, automobiles, machinery manufacturing, steel, metallurgy, petroleum, etc., providing technical equipment for the technological transformation of traditional industries and the modernization of manufacturing.

Laser quattuor characteres habet comparata ad lucem ordinarem: monochromatitudinem (longitudo waverum unius), coherentiam, directionalitatem et altam intensitatem. Laser trabes facile transmissi sunt, et tempus et characteres spatiales eorum separatis controlli poterunt. Post focussimum, parva puncta lucusta accipere potest. Trabes laser cum densitate potentiae conflavere et vaporizat omnes materiae, et inter regiones locales materiae cito procedere potest. Introductio caloris ad opus in processione parva est, et terram caloris et deformationem caloris parva sunt; Excelsa processionis effectivitate; Easy to implement automation. Tecnologia Laser a campus maximus tecnologiae est qui disciplinas quales opticas, mechanicas et electronicas involvet. Similarly, laser processing equipment also involves many disciplines, which determines its high-tech nature and high profitability. Through years of research and development, as well as improvement in the domestic laser application situation, contemporary lasers and laser processing technologies and equipment have become quite mature, forming a series of laser processing processes.

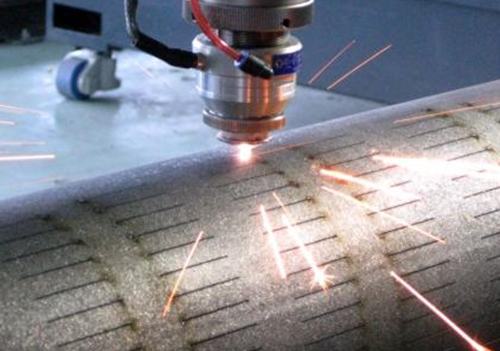

Now, the editor of Shenyang Laser Cutting will introduce the application of laser processing technology in metal cutting.

1. Characteristics and Applications of Laser Cutting

Laser cutting is currently a widely used laser processing technology in various countries. In many fields abroad, such as automobile manufacturing and machine tool manufacturing, laser cutting is used for the processing of sheet metal parts. Con continuum meliorem qualitatem lignorum laserorum altissimi potentiae, varium processionis objecti laserorum cutationis extensivius erunt, inclusive quasi omnes metallos et non metallos materiales. Exemplo, laser cutatio potest utilizat ut tribudimentiam partes materialis cum alto duritate, angustia, et puncto conflationis, quod est etiam avantia laser cutationis.

Shenyang laser cutting

Hodie, industria, quas elegerit sistemas de laser cutatione, in duas categorias divisa sunt: unus est grandis et medius industria, qui producunt multum lapides, quas secere et secere oportet, et fortis potentias ekonomica et technologica. The other type, collectively known as processing stations, specializes in undertaking laser processing business externally. Its existence can meet the processing needs of some small and medium-sized enterprises on the one hand, and on the other hand, it plays a role in promoting and demonstrating the application of laser cutting technology in the early stage.

Claves technologies laser cutationis sunt tecnologia integra lux, machinae et electriciae. Parametri ligni laseris, et exercitus et precisio machinae et systemae CNC, directe effectivitatem et qualitatem laseris cutationis influent. Precisio, efficientia, et qualitate laserorum cuttionis variantur cum diversis parametros, sicut cutting power, speed, frequency, material thickness, et material, ita dives experience of operators is particularly important.

1.1 Main advantages of laser cutting

(1) Good cutting quality: narrow incision width (generally 0.1-0.5mm), high precision (generally hole spacing error 0.1-0.4mm, contour size error 0.1-0.5mm), good surface roughness of the incision (generally Ra 12.5-25 μ m), and the incision generally does not require secondary processing for welding.

(2) Velocitate velocitatis sectionis, ex exemplo, energia 2kW laser is, velocitas octo mm caloris carbonis fertilis est 1.6m/min; Velocitate caloris sterilis caloris cum densitate 2mm est 3,5m/min, cum parva caloris zona et minima deformatio.

(3) Clean and pollution free, greatly improved the working environment for operators.

Laser cutting belongs to non-contact thermal processing and is known as a "wear-resistant tool". Laboratores constantly packatur aut in omni forma secere potest ut materiales raw utilizat. A causa non-contact processionis, distortio parterum processionis reducitur ad inferiorem nivellum et quanta portarum minima est.

In fact, laser cutting has also its shortcomings. In terms of accuracy and cutting surface roughness, laser cutting has not surpassed electrical machining, and in terms of cutting thickness, it is difficult to reach the level of flame and plasma cutting. In addition, it cannot perform molding, tapping, and folding like a turret punch press.

1.2 Comparison between laser cutting and punch press

Previously, the Sheet Metal Processing industry used traditional punching machines for stamping, but later developed into CNC turret punching machines and composite machine tools. With the progress of society, laser cutting technology has also been introduced in the metal processing industry, and has become a rapidly developing and widely used processing method for sheet metal cutting in industry. According to informal statistics, China has accumulated over 500 laser cutting systems used in industrial production, accounting for approximately 2% of the world's total operating systems.

In the metal processing industry, laser cutting is widely used for low carbon steel with a thickness of no more than 20mm and stainless steel with a thickness of 8mm. Most of the sheet metal parts have complex contour shapes and small batch sizes, such as automatic elevator structural parts, elevator panels, machine tool and grain machinery covers, various electrical cabinets, switch cabinets, textile machinery parts, engineering machinery structural parts, large motor silicon steel sheets, etc. In addition, some metal patterns, logos and fonts used in decoration, advertising and service industries can also be manufactured using laser cutting.

CNC turris punching machine suitable for mass production of products with simple shapes. Produkti electricali cabineti, communication system exchange cabinets, elevator door panels and handrail panels, steel furniture, etc. Compared with CNC bricks tower punching machines under the same cutting and stamping conditions, laser cutting machines are generally more expensive, but due to their flexibility and other advantages (such as laser cutting only needs to cut according to the drawing shape, and there is no need to manufacture molds, which shortens the production cycle). In recent years, some manufacturers have gradually realized the high benefits it brings. In order to enhance market competitiveness, companies have purchased laser cutting machines to adapt to various types of products while owning multiple CNC brick tower punching machines. Utrum non dicens machinas laseros concidiant ad machinas punching turris CNC, magis oportet dicere inter se complementare.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque