Isolat cannabis extrusion mortuus est. Spero quod veteri operarii ferreorum qui interesantur in hoc agro devenire non errabunt, et simul principes tecnicorum ad discutionem nostram per micro micro participantes ad coniunctionem technologiae extrustionis frigidae micro precision.

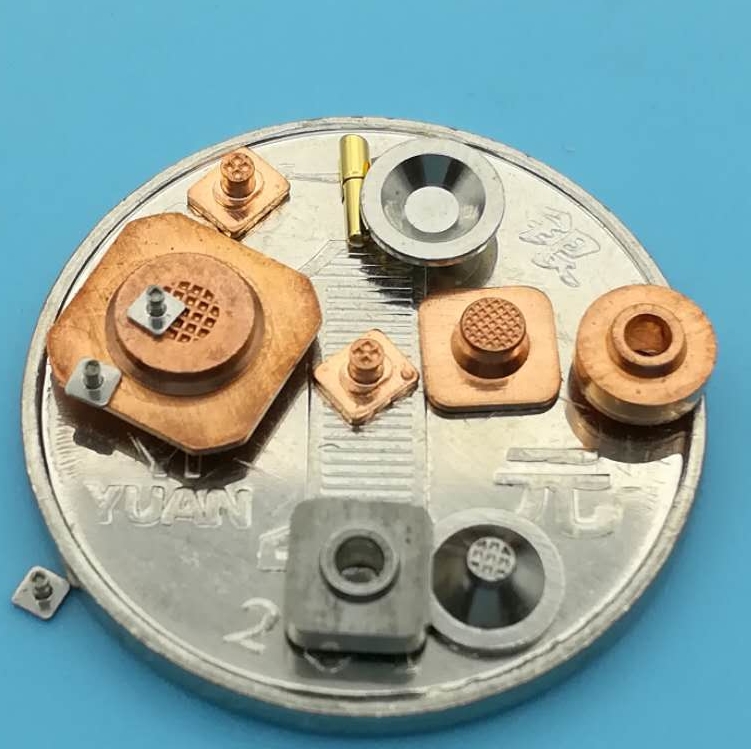

In terms of micro precision cold extrusion technology, extrusion cold extrusion est, nondum est extrusion cold extrusion, sed est a micro et altior precision cold extrusion technologia.et precisa. Extrusiones Microelectronicae precision frigidae partes facile miliones aut etiam decem milionum particularum per ordinem producere potest. Si adhuc modos de manu manus manus extrussione frigidae ad produktionem utilizatis, tempus est classem frustra finire! So the research and production of micro precision cold extrusion technology has become increasingly important, which is why we need to talk about the topic of microprecision cold extrusion technology.

Aedificium electae extrusion is et extrusionis calidissis extrusionis calidibus continebantur ipsum continua productivitate, et arma utilium est etiam velovelo punching machinae. Nur velovelo punching machinae potent confitere magna productione quae sunt in clientes. EMAR's mature mols nunc permanent a punching veloculitate 260 vic in minuta, quae non potest in necessitate pluris clientibus. Speeda non esse multa celes. Si velos est nimis celes, cooling velos punch non potest sustinere, et damdamagin inserti non valet perdam. NumNumNumNumeros clientibus est nimis magnis, ita ut nobis apeendi aliquibus pluris opere facimus fabrorum! Ha-ha!

The design of micro precision cold extrusion mold s should consider their continuous productivity. The embryo needs to be formed in many steps inside the mold, because cold extrusion processing is not like stamping processing, and the pressure is very high, reaching more than 2000MP. Therefore, the guide columns must not be too small or too few. When you encounter product design, you must fully consider this point, otherwise the product production will be unstable for a period of time, and you cannot find the reason. EMAR's years of experience tell you this is very important!

The most important mold structure in the design of micro precision cold extrusion molds is how to accurately feed. If the feeding method is not precise, it will seriously affect the yield rate of the product. EMAR Hardware has taken many detours in this regard. Currently, two sets of feeding methods are used, and a patent certificate has been applied for this production method. Therefore, it is not convenient to disclose more information to avoid touching the line!

The design of micro precision cold extrusion molds still needs to follow the principles of cold extrusion design. Regardless of the convex and concave molds, the flow of metal should be easy, especially the design of metal dead nodes should be smooth. If the effect can not be achieved, it can be divided in multiple designs to gradually achieve the desired shape. Do not design in one step, otherwise the damage speed of the punch will make your repairman even more tired than a dog!

Lubrication est tale factor clave in productione extrusion is frigidis micro precision, qui seriously affectus est vitam moldae. Hardware EMAR multos detours in R&D et productione fecit. Finally, it was the solutions given by professors of the Materials Research Institute of Shanghai Jiaotong University that solved these headache problems, basically replacing the phosphating and saponification lubrication process. Now the production is very smooth. In this regard, old irons need EMAR to provide assistance.

Old irons, I can only mention the matters that should be noticed in the design and production of micro precision cold extrusion die. Welcome to have orders in this regard and use EMAR hardware to help you produce, or pay a patent fee for the technology provided by EMAR hardware!

Existing EMAR precision cold extrusion production videos, welcome to visit!

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque