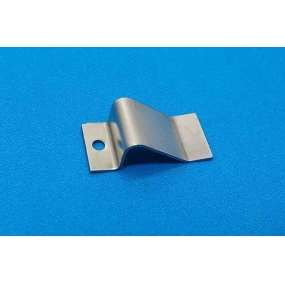

After the installation of the stamping die, a comprehensive inspection and examination of the quality of the stamping part and the performance of the die should be carried out. Regarding the problems that occur during the trial stamping stage, a comprehensive analysis should be conducted to identify the causes of the problems, and appropriate adjustments and corrections should be made to the stamping die to ultimately achieve qualified stamping products.

So what is the intention of trial punching and adjustment of stamping parts molds?

1. Determine qualitatem partium et fuscinum pulsavorum Confirmate conditiones formationis parterum clausum

3. Confirm the blank form, dimensions and material specifications of the formed parts and products;

In productione stampionis morientur, difficile est accurately calculati granditudinem et formam vacuum antequam deformationem dum planatur aliquid partibus stampionis cum formis complex is aut precisiis altis necessitatibus, such as bending, deep drawing, forming, cold extrusion, etc. In order to obtain more accurate form, scale and material specifications, it is only necessary to repeatedly adjust the mold to produce qualified parts before confirmation.

4. Regarding some process scales that are difficult to confirm using calculation methods in mold planning and process planning, such as the complex convex and concave die corners of deep drawing dies, or the geometric shapes and scales of certain parts of the mold, it is necessary to conduct trial punching and adjustment at the same time until qualified parts are punched out, and the shapes and scales of these parts can finally be confirmed.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque