Mechanical processing and numerical control processing are two different processing methods, and there are some differences between them.

First, mechanical processing refers to the process of using traditional machines for machining. Haec instrumenta machinae includent machinas militias, machinas drilling, machinas grinding, lathes, etc. In processione mecanica, operatores manum constituent movementum instrumenti machinae et profunditatem machinae instrumentorum secendi secundum tecnologiam processionis et necessitates drawingis. Procedus processionis huius methodos relative simplex est, sed opus facientibus quaecum experientiam technicam et proficientiam habere debet.

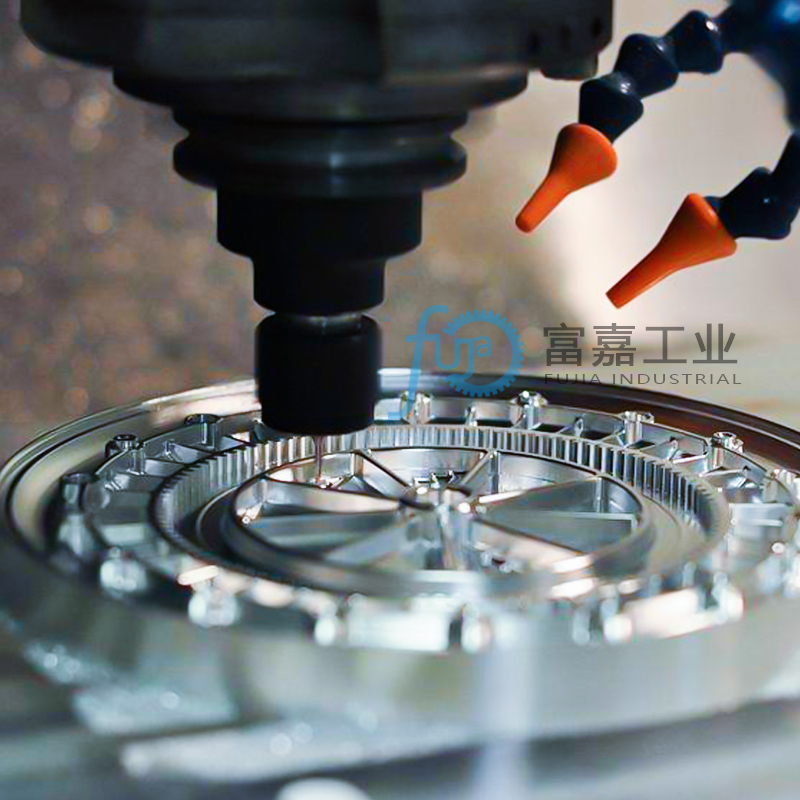

Numerical control machining refers to the process of machining machine tools through a computer control system. Numerical control machining mainly relies on digital programming and automated control systems, which enable the machine tool to process according to specified paths and speeds through pre-set programs. In machinatione CNC, operator solum est responsabile pro scribere programmam machinationis, et tunc programmam in systemam controlli computatorii inponere, et instrumentum machinationis operationem correspondentem secundum programmam executabit. Compared to mechanical processing, CNC Machining has a higher degree of automation and accuracy.

Secundo, precision machinae mechanicae et machinae CNC differt. Due to the fact that mechanical processing is controlled by manual operation, the technical level and experience of the operators have a significant impact on the machining accuracy. Numerical control machining can accurately control the machining process through pre-set programs, thereby improving machining accuracy. In addition, CNC machining can also perform automatic compensation, adjusting the program according to the degree of wear of the machine tool to maintain the stability of machining accuracy.

In addition, the production efficiency of mechanical processing and CNC processing also varies. Due manual operation required for mechanical processing, the processing speed is relatively slow, while CNC machining can automatically perform processing operations according to the settings of the processing program, improving production efficiency. Therefore, in situations where large-scale production is required, CNC machining is more suitable.

In addition, there are certain differences in the scope of application between mechanical processing and numerical control processing. Mechanical processing is suitable for processing some simple parts, such as holes, slots, excavations, etc. CNC machining can perform more complex machining, such as surface machining, combination machining, etc. Numerical control machining can also perform multi axis linkage according to the requirements of the machining task, achieving more precise and complex machining operations.

In addition, CNC machining also has some other advantages. First, CNC machining allows continuous processing without the need for downtime or tool changes, thereby improving production efficiency. Secondly, CNC machining can produce multiple varieties and small batches to adapt to changes in market demand. In addition, CNC machining can also perform simulation machining, reducing the time and cost of experimentation and adjustment through computer simulation of the machining process.

In short, mechanical machining and numerical control machining are two different processing methods. Mechanical processing relies on manual operation, with relatively slow processing speed, low accuracy and stability, and is suitable for simple part processing. Numerical control machining depends on computer control, has a high degree of automation and machining accuracy, and is suitable for complex part machining and large-scale production.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque