To understand the working principle of a small machining center, it is necessary to clarify first the components of the small machining center. The small machining center is mainly composed of five parts: numerical control system, detection device, drive device, machine transmission chain, and servo motor. Each part has special functions. Below, we will introduce their respective working principles from these five parts, so that everyone can have a certain understanding of the small machining center.

Part 1: Numerical Control System: Equivalent to the brain of a small machining center, it needs to process electrical signals from detection devices, drive devices, and servo motors, clarify the overall status of the machine tool, and make instructions for the next step of work. Exemplo, parvus machinatorium centrus imperium mutationis instrumentorum executus est. The detection devices involved include servo motors, spindle clamping tool sensors, and tool magazine number sensors. The system determines the spatial position of the spindle movement through the servo motor, determines whether the tool is installed on the spindle through the spindle clamping tool sensor, and confirms the tool number on the tool magazine at this time through the tool magazine number sensor. The final control system uses signals transmitted by different detection devices at different times as reference data to make the next action. The numerical control system directly determines the stability of small machining centers, so careful selection of the system is necessary.

Part 2: Drive device: equivalent to the cerebellum and brainstem of a small machining center, it can process some low-level signals such as speed and position signals transmitted by servo motors. He helped the system handle a large number of tedious tasks while directly controlling the operation of the servo motor. Utrum et carmen eius gravissima est.

Part Three: Detection Device: Equivalent to skin, eyes, and ears, it needs to collect the status of the machine tool through sensors to provide motion data reference to the system. Sensore defecit, ut instrumentum machinae non acciperet correspondentem signum, multo magnificabit tempus accidenti.

Part is quattuor: Servo Motor: Equivalent corde, est principium fontem potentiae parvulorum centrorum machinarum. A causa aedificationis positionis et sensorum velocitatis, ut apparatum detectionis partialis servit, et idcirco servo motor directo determinat precision instrumenti machinae.

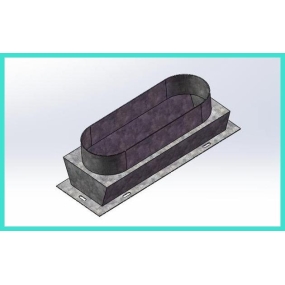

Part 5: Machine Tool Transmission Chain: It is equivalent to the muscles and limbs of a small machining center, which can transmit the power of servo motors and achieve the purpose of power transmission. Componente mecanica est, qui prima precision instrumenti machinae determinat.

Cum intellegeremus quinque componentes importantes centri minimi machinae, melius intellegere poterimus principium eius. Parvus centrus machinae transmit signos ad systemam per apparatum detection is, et system a dat instructiones actionis. chainus driver et transmissionis actionem executur, et finem apparatus detectionis respondit signum actionis. Sistema iudicat quod mandatum executionis completum est. Hoc est principum operantis parvuli machinae centri, et credo intellegere principem parvuli machinae centri habere vitam guidantem in elegitione unum.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque