Quomodo determinare parametros laserorum in Shenyang?

Praepositus laser cutus

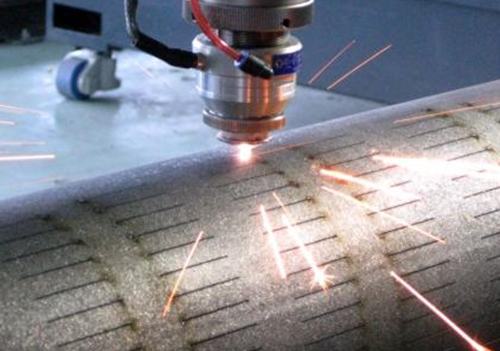

Laser cutting processing replaces traditional mechanical knives with invisible beams, and has the characteristics of high precision, fast cutting, not limited to cutting patterns, automatic typesetting to save materials, smooth cutting, and low processing costs. It will gradually improve or replace traditional metal cutting equipment. Partis mechanics lapidis laseris non habet contactum cum operibus et non inducet lapides super superficiem opus in operibus Laser cutus velocitus est, incisio planctus et flatus est, et generis non requirit ultra processionem. Terra caloris concidit parva est, deformatio tabulae parva est, et summa concidit (0.1mm~0.3mm); incisio non habet stressum mechanicam nec tunicam ardentem excelsa precisa procedentium et repetitionem bonam et nulla malum facie substantiae Numerical control programing, capable of processing any flat plan, can cut large entire boards without the need for molds, saving time and economy.

Composition of laser cutting equipment

Laser cutting equipment mainly consists of laser, light guide system, CNC motion system, automatic height adjustment cutting head, work platform, and high-pressure gas blowing system. Multi parametros poterunt influentiare proceduram laser cutationis, quidam ex eis dependant on the technical performance of the laser and machine tool, while others are variable. Parametri principes laserorum sectionis sunt:

Main parameters of laser cutting

Modus Beam 1

Modus fundamental, etiam Gaussian modus cognoscit, est modus ideal is secendi, prima in laseribus minimis potentiae cum potentia minus quam 1kW.

2 laser power

Laser power required for laser cutting mainly depends on the cutting material, material thickness, and cutting speed requirements. Laser power has a significant impact on cutting thickness, cutting speed and incision width. In general, sicut laser potentia incrementatur, densitudo materiae, quoque succidentur, crescit velocitas, et amplius incisionis crescit.

3 Posiciones Focus

Posicio focal significa implevit in latitudine incisionis. In general, focus is chosen to be located about one third of the thickness below the material surface, with a larger cutting depth and a smaller mouth width.

4 focal moments

Cum praecideret plateas aeneas debiles, trabem longius longitudinis focalis utilizatur ad possidendum faciem succidentem in bona verticalitate. Profunditudo fokusae crescet, diameter lucis quoque crescet, et densitate potentiae consequente diminuit velocitatem. Quidam velocitatem concussionem sustinere necesse est laser potentiam crescere. Consolitabilis est trabem cum minimo longitudine focale ad secendum plateas thinas, quod resultat in minimo diameter punctus, alta densitate potentiae, et velocitate caligare.

5 gases auxiliary

Carbonum altum calorium saepe oxygenum utilizat sicut gasum succidentem ad promotionem procedentis succidentem utilizat calorem reaction is combustionis oxygeni ferri. Plus, velocitas succidentem celeriter est, qualitate succidentem bonum est, et carmen libera succidentem potest accipere. Presio crescet, energia kinetica crescet, et capacitatem discargentem plagam crescet. Presio sequitur constituetur super factores, quales materia, densitate plateae, velocitatem sequitur et qualitatem superficie sequitur.

6 nozzle structure

Struktura et forma nozzle, et granditudo lucis outletum, etiam qualitatem et effectivitatem laserorum cutationis influent. Differentium necessitatibus cutationis inter usum variorum nozzlerum require. Forma nuzzle usus cylindrica, conical, quadrata et cetera forma includent. Laser cutting generally uses coaxial (air flow concentric with the optical axis) blowing method. If the air flow is not aligned with the optical axis, a large amount of splashing is easily generated during cutting. To ensure the stability of the cutting process, it usually necessary to control the distance between the nozzle end face and the workpiece surface, which is generally 0.5-2.0mm, in order to facilitate smooth cutting.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque