Nunc quales partes stampionis sunt, partes stampionis fabricatores mensuras technicas opus sunt ut bonum qualitatem et operationem securam possint in medio stampionis. Nunc bene facientes in technologia qualificationem et qualificationem stampionis molum meliora possunt. Si fabricatores pulsere volunt complicere opus qualificatis partibus pulseris et stabilis productionis, tecnologiae coepere opus est.

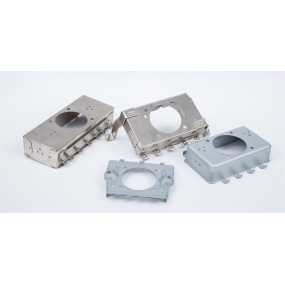

What are the technical requirements for stamped parts

Although stamping parts and sheet metal forming have some similarities, they are not entirely similar. Tabulae metalla formantur metalla folia utilizat, cum tubis tinctis et profilis tinctis pulveris quasi materiales crudelis.

When designing Metal Stamping parts, it is necessary to combine materials to achieve the rationality of stamping molds, the service life of stamping molds, and focus on improving the production stability, quality, efficiency, and other aspects of metal stamping parts to comprehensively consider the design.

In addition, stamping manufacturers should choose suitable materials during stamping, and the formed metal stamping parts should avoid contact with convex and concave products to avoid damage. When designing stamping parts, stamping manufacturers should consider the position of mechanical devices and replace manual operations with mechanical and automatic devices when necessary.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque