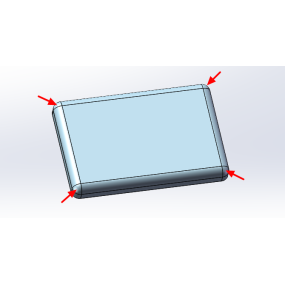

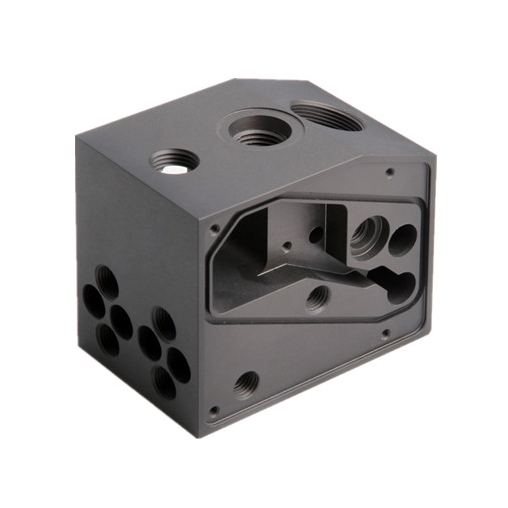

CNC quinque axis machinatio multitudinem significantiam habet in productione, ut non placeat in agro industriae parterum complexorum. The following are the main advantages of CNC five axis machining: Strong ability to machine complex surfaces: Five axis machining machines can move in five directions simultaneously, including three linear axes (X, Y, Z) and two rotational axes (A, B or A, C). Hic flexibilitate quinque instrumenta maquinae axis ut faciem complexam et partem irregularam procederet, sicut aeroplanes blades, molds, etc., quas instrumenta tres axis maquinae tradicionale non potest correspondere. Improvens machinaturae accuracionem: dum quinque machinatura axis, instrumentum optimum angulum cum superficie operantium semper manere potest, ut reducat fortitudinem et vibrationem, et optimum machinatur accuracionem et qualitatem superficie. In addition, five axis machine tools are usually equipped with high-precision control systems and detection devices, which can monitor and adjust the machining process in real time to ensure machining accuracy Reduce frequencatem clampionis: In quinque axis machinatura opera in multis superficies in una clampionis potest, reddere errores causas multiclampionis et positionis. This can not only improve production efficiency, but also reduce production costs and processing cycles Improving material utilization: Five axis machining can achieve processing of complex shapes, allowing previously difficult to process waste materials to be used and increasing material utilization. Meanwhile, five axis machining can also reduce the amount of waste and cutting fluid used during the machining process, and lower environmental pollution In processo novorum produktorum disveloppationis quinque machinae axis celeriter exemplos aut prototipus designorum et inženieribus ut evaluerent et meliorem, ut breviaret cycle disveloppationis Reduce productiones: Quando primum investimentum in quinque axis machinae machinae relative altae est, in longo tempore quinque axis machinae productionem constituent. In unam partem quinque machinae axis effectivitatem productionis et utilizationem materiae meliora potest; On the other hand, five axis machining can reduce errors and scrap rates caused by multiple clamping and positioning, thereby lowering production costs Strong adaptability: Five axis machining machines have strong adaptability and can process works pieces of various materials, shapes and sizes. Utrum metallis, plasticis, aut materiales compositi sunt, quinque axis machinatio facile eos manere potest. Hoc facit quinque partes machinae in aerospace, automotiva, molda, medicina et ceteris regionibus.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque