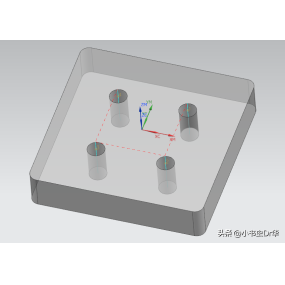

Detection and quality control during the processing of optical communication components are key links to ensure the performance and quality of the components. Secundus est analys detalior huius procedentis: 1. Inspectio Step 1. Importantia mensurae dimensional is: Precisio dimensionalis componentium communicationis opticae crucial est ad assemblandum et actionem eorum. Metodo: Uter instrumenta mensurae alta precision pro mensurae mensurae, sicut caliperi vernier, gauges altitudinis, micrometri etc. Requirementum: Assecura quod dimensiones parterum requiribus design conformentur et quod tolerantiae inter regionem permissibilem constituuntur. 2. The Importance of Geometric Tolerance Detection: Geometric tolerances reflect the shape and positional accuracy of parts. Method: Use optical measuring instruments or coordinate measuring machines to detect geometric tolerances. Requirement: Ensure that the geometric tolerances of the parts meet the design requirements to meet the requirements of assembly and use. 3. Importantia testationis mechanicae exemplationis: Perfectionis Mechanical reflect key properties such as strength and durability of parts. Methoda: Conducte testos functionis mecanica, quasi extensionem, compressionem, et bending ad assemblandum proprietates mecanica parterum. Requirement: Ensure that the mechanical properties of the parts meet the design requirements to meet the usage requirements. 4. Importantia probationis opticae opticae exercitus est unus de proprietatibus opticae communication is componentibus. Methoda: Uter instrumentos mensurae opticos ut probare parametros, sicut index refractive et attenuatio fibris opticos. Requirement: Ensure that the optical performance of the parts meets the design requirements to ensure efficient transmission of optical signals. 2,Quality Control Step 1: The Importance of Raw Material Control: The quality of raw materials directly affects the performance and quality of parts. Measures: Vere scrutare et videre materiae raw, ut certat qualitatem suam requiribus. 2. Importantia procedentis in machinis: Control during the machining process is crucial for ensuring the quality of parts. Measures: Strictly control every step of the machining process, such as evaluating tool life and adjusting machining parameters, to ensure the stability of the machining process and the quality of the parts. 3. Importantia inspection is qualitatis et feedbackis qualitatis inspectionis est modo importantis ut qualitatem parterum asseguratur. Mesura: Multiquales inspectiones qualitatis in partes per processionem facite et facite quicquam causam. At the same time, establish a quality inspection feedback mechanism to promptly provide the inspection results to the processing personnel, so that to adjust the processing parameters and improve the processing technology in a timely manner. 4. Importantia SPC control: SPC control (Statistical Process Control) est method used to monitor and control the production process. Aplicatio: In processione componentium communicationis opticae, control SPC ad dimensiones importantes potest ut impederet posibiles abnormalitates in processione, ut non evaderet reparationem aut scrappationem produktorum.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque