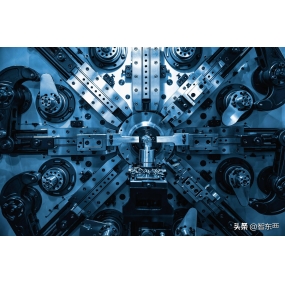

In order to prevent cracking in CNC processed parts, the following measures can be taken to ensure the smooth progress of the processing process and the quality of the processed parts: 1. Raw material selection and inspection. Select high-quality raw materials: Ensure that the raw materials used, such as acrylic sheets, aluminum shells, etc., have sufficient hardness, purity, and thickness to meet the processing requirements· Check the quality of raw materials: Conduct quality checks on raw materials before processing, including measurements of hardness, purity, thickness, and other parameters, to ensure that the raw materials are defect free and crack free. Adjustion of CNC Machining parameters and cutting speed: Set the cutting speed reasonably according to the hardness and thickness of the material. Normally speaking, cutting speeds that are too high or too low can lead to the formation of cracks· Flumen rate: Set the feed rate reasonably based on the cutting speed and tool selection. Excessive feed rate can result in excessive cutting force, leading to cracks Eleccio instrumentorum: Elegite instrumenta adequa pro processione materiae ut assecurat difficile et resistentiam instrumentorum resistentiam confortare. For materials with high difficulty, tools with good wear resistance should be selected Metodo frigidae: Assecura quod modo frigidae sufficit et adequat ut non efficiat fracturam thermalam aut fracturam frigidam causam ab supercaliente aut superfrigido. Use appropriate cutting fluid and cooling system to reduce cutting temperature. 3, Optimizatio procedentibus et clampionis opus: assecura ut opus in modum machinatorium clampitur, ut non efficiat fractas causas per vibrationem. Use appropriate fixtures and clamping methods to ensure the stability of the workpiece· Optimizatio gressus instrumenti: Reasonabile design the tool path to avoid excessive cutting force during the machining process. Uter software CAM professional pro optimizatione designa ut optimizare machinae efficabilitatem et qualitatem meliorem Processing sequence: Reasonably arrange the processing sequence to avoid excessive stress concentration during the processing. For complex machined parts, step-by-step or pre-machining methods can be used to reduce the occurrence of cracks. 4,Equipment maintenance and upkeep · Machine tool maintenance: Regularly maintain and upkeep the machine tool to ensure its accuracy and stability. Check if the transmission system, lubrication system, cooling system, etc. of the machine tool are working properly· Tool maintenance: Regularly maintain and replace tools to ensure their sharpness and wear resistance. Utrum vasa gravis operibus utilizat in machina ut occurrentiam fragmentorum redderet. 5 · Training and Skill Enhancement · Training: provide professional training to operators to enhance their operational skills and safety awareness. Assecurate operatores cognovere operationem et precautionem machinationis CNC Skill enhancement: Encourage operators to continuously learn new knowledge and technologies, improve their processing skills and quality awareness. Operatorum enthusiasmum et creativitatem inter scientias competitiones et mercedes mecanismos stimulare.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque