Precision Sheet Metal Processing is a professional processing technology mainly used for manufacturing high-precision metal products. Flumen processionis generis sequentes gradus includet:

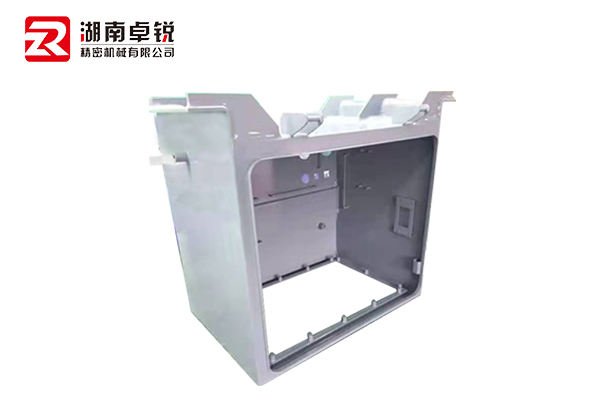

1. Design and Drawing: Before starting processing, design and drawing are necessary first. Develop a product design plan based on customer needs and requirements, and draw detailed manufacturing drawings according to the design plan.

2. Material preparation: Before processing, it is necessary to prepare the required sheet metal materials. secundum opus diagrammarum designorum, elige materia adequata et secere et organiza eas pro subsequente processione et uso.

3. Cutting and Forming: Place the prepared sheet metal material in a CNC cutting machine or CNC bending machine for cutting and forming. secundum propositiones diagrammatis, accurately cut and bend to ensure the accuracy and quality of the product.

4. Gravitatio et ecclesia: Gravitatio et ecclesiae quae secessi sunt et formati sunt. Use welding equipment to weld sheet metal parts together and perform necessary assembly work to complete the manufacturing of the product.

5. Trepta superficie: trakta superficie produktorum processorum, sicut spraying, sandblasting, plating chromae, etc. Surfacie tratatio optima videntiam et durabilitatem produktorum potest.

6. Inspectio qualitatis: Inspectio qualitatis post processionem completum conducite. Examinantes dimensiones, apparentias, structuras et alias aspectos produkti, assecurate ut conformetur propositiones design et habet bonam qualitatem.

7. Packaging and Transportation: Packaging and arranging transportation for products that have passed quality inspection. Assecurate quod productum in transporto non detrahitum est et manet intactum quando emptor manus attinget.

Superior est principium processionis metallorum lapidum precisii, et unusquisque gradus operationem prudentiam et controlum strictum opus est ut qualitatem et precisitatem produkti assegurat. Precision sheet metal processing technology has a wide range of applications in fields such as automotive, aerospace, and electronics, and is of great importance for improving product quality and performance.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque