in vita quotidian multi pulchritudinis pretium et delicatum et pretium requirunt Quid sunt criteria processionis partibus precisiis?

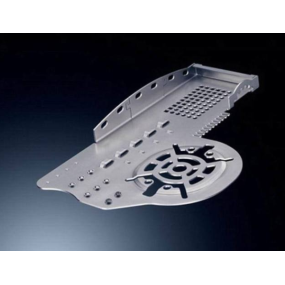

1. Criteria precision: The number of processes involved in deep drawing and stamping parts processing is related to material properties, deep drawing height, number of deep drawing steps, as well as deep drawing diameter, material thickness, and other conditions. It needs to be calculated through the deep drawing process before adjustment can be made;

2. Criteria precision: Numero procedentium involvit in processione partium stampionis curvatorum prima dependit de grado disorderis in forma structural, et necesse est determinare based on the number, relative direction, and direction of the curvatoris;  3. Exquisite principe: When precision stamping parts have high requirements for cross-sectional quality and standard accuracy, it is possible to consider adding a trimming process or selecting a precision punching process for diameter after the punching process;

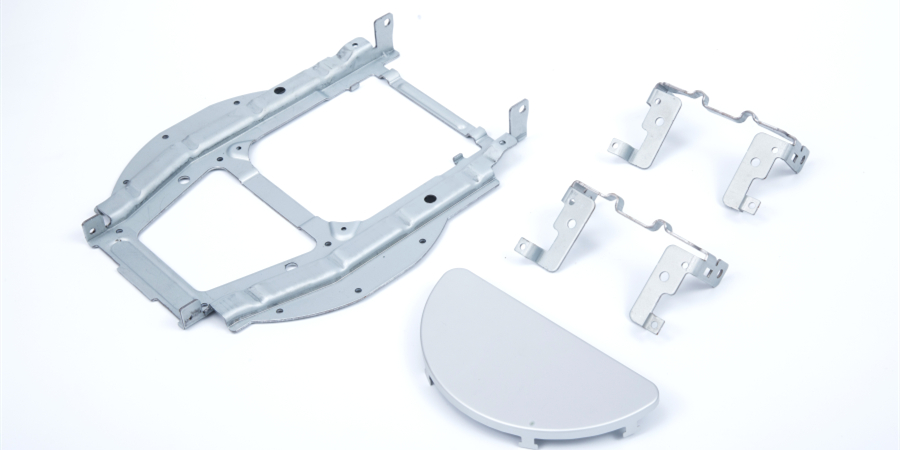

3. Exquisite principe: When precision stamping parts have high requirements for cross-sectional quality and standard accuracy, it is possible to consider adding a trimming process or selecting a precision punching process for diameter after the punching process;

4. Criteria precision: When punching workpieces with simple shapes, a single process mold can be used to complete the process. However, when punching workpieces with messy shapes, the structure and strength of the mold are limited, and the table should be divided in several parts for punching. Multiple stamping processes should be selected, and continuous molds can be used if necessary.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque