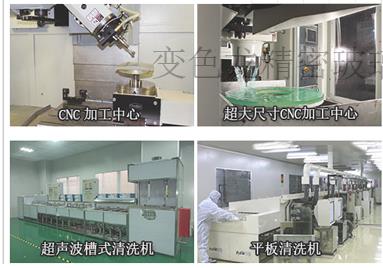

CNC Machining and ultrasonic machining of quartz glass

Our cutting-edge capabilities include precision glass CNC machining services and ultrasonic machining.

Quando similes computatorium technologies utilizant, vitra CNC machinatura et ultrasonica machinatura habent diversas characteres, facientes ea optiones ideales diversis aplicationibus. Below, we will discuss the subtle differences between glass CNC machining and ultrasonic machining to help you choose the process that suits your needs.

Quid poculum CNC machina est?

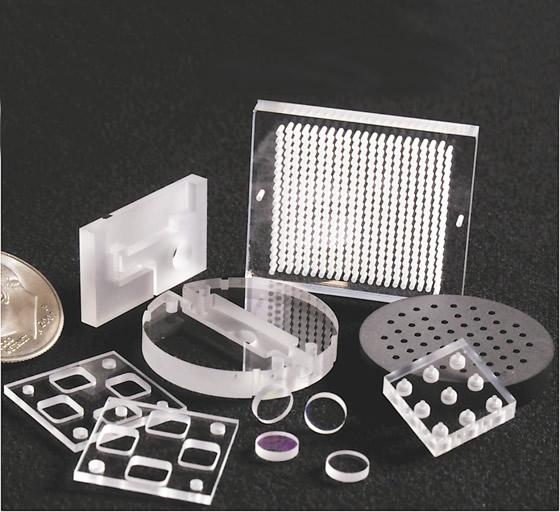

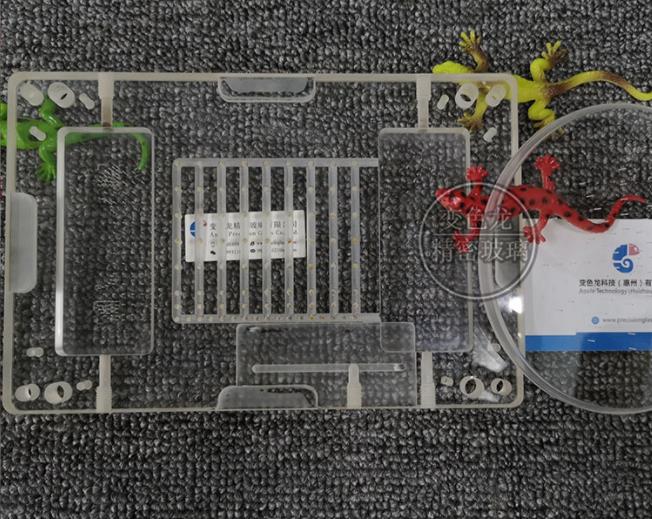

Glass CNC machining, also known as glass milling, uses computer-controlled tools to accurately remove materials from glass workspieces. CNC machining allows operators to cut and shape workpieces on multiple axes, and can be used to create various sizes, shapes, and features such as grooves, grooves, and holes.

Precisio et versatibilitate machinae CNC vitreorum optime facit illud pluribus aplicationibus et industriis, includit:

Aerospace/Defense: CNC machining is used to manufacture instruments, instruments, and other components with complex shapes.

Biotechnology: Biotechnology companies use CNC processing components such as flow pools to promote material flow through precision channels and cavities.

Semiconductor: The semiconductor industry uses precision CNC processed glass for wafer stages, reference frames, windows, and lenses.

Telescopes: Telescopes et microscopes speculatores et lenses multo precisa et stabilia requirunt, quod tantum per machinam precision CNC prodicere potest.

Quid machina ultrasonica est?

Ultrasonic machining, sometimes referred to as ultrasonic drilling, uses abrasive slurry and ultrasonic vibration to remove material from glass pieces. Unlike cutting and grinding, the slurry removes traces at once and finely grinds the desired shape in glass. Lex porta eliminat possibilitatem accumulationis stressi in opus, id est nulla structura crystali et fortitudo vitrae.

Ultrasonic machining has a wide range of applications and can be used to create cavities and holes of different shapes, sizes, and depths, including height specific external diameter (OD) and internal diameter (ID) features. industria quae beneficiant ex ultrasonico processione vitrorum componentum includent:

Aerospace: Ultrasonic processing is used to manufacture pressure sensors, flight instruments, and other sensitive glass components in aircraft and aerospace equipment.

Automotivus: Ultrasonic processed glass forms advanced sensors for proximity detectors, backup applications and other safety functions.

Medical: Various medical devices include glass components processed using ultrasonic methods.

Semiconductor: Semicoconductor industria saepe vitrum ultrasonici processum pro chips, electrodes, tabulis distributionis, lenses et speluncis utilit.

CNC machining and ultrasonic machining

Although both glass CNC machining and ultrasonic machining are used to manufacture precision glass components, each method provides unique advantages for specific applications.

Glass CNC machining has a wide range of applications and can be used to manufacture complex components with extremely small tolerances. Altera beneficia CNC quartz glass processionis est potestas producere componentes precisas cum minima manu supervisione.

Ultrasonic machining can produce precise shapes, holes, and cavities on extremely hard glass that is difficult to mill. Procedentia ultrasonica minus stressum super vitro materiales, componentes fortiores promontes, ut illud multo adequatur ad aplicationes criticas et alta pressione operationes.

Procedentia ultrasonica non deform it neque concipit vitrum, perfecta est opus componentibus qui multiplicas holas et speluncas requirant. Extulere graduale minimae substantiae superficii ultrasonicae machinae in profunditates pretiosas fluent. Unlike CNC milling, ultrasonic machining can drill multiple holes at high speed and accuracy without affecting the integrity of the workpiece. For complex glass components with many holes, this may be a very effective and cost-effective large-scale production method.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque