Quid causae minimae productivitates in laser cutatione sunt?

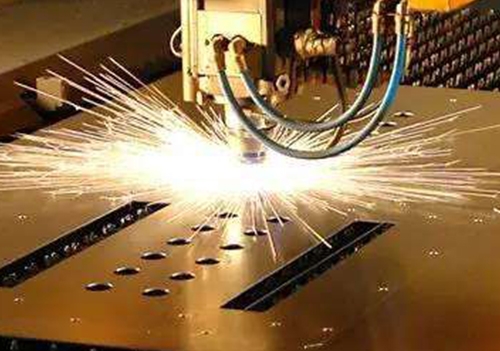

One of the reasons why laser cutting is widely praised in the metal processing industry is its high production efficiency and low processing cost, which has significant advantages compared to other cutting methods. However, many customers have found that their production efficiency has not improved significantly after using it for a period of time. What is the reason for this? Below we will explain the reasons for the low production efficiency of laser cutting.

1. No automatic cutting process

Laser cutting does not have an automatic cutting process and cutting parameter database on the system. Cuting operators can only manually draw and cut based on their experience, and automatic perforation and cutting cannot be achieved during cutting, requiring manual adjustment. Over time, the efficiency of laser cutting will naturally be very low.

2. Inappropriate cutting method used

Cum lapides metallis secissent, extremis extremis, extremis protulissent, pondus et alias metodes cutationis non sunt utili. In hoc modum, cessa longa est et tempus concussionis longa est, resultat in low productivity efficientia. In ipso tempore, multa consumptionis etiam crescet, et ad excelsa costa expenditur.

3. Software nestationis non utilizat

Programma nestationis non est usata ad testationem et secendum sed manum scriptationem in systema executa est, partes secundum ordinem secessi sunt. This will result in a large amount of scraps being generated after cutting the board, low utilization rate of the board, and the cutting path not being optimized, leading to long cutting time and low production efficiency.

4. The cutting power does not match the actual cutting thickness

Not selecting the corresponding laser cutting according to the actual cutting situation. Exemplo, si magna quantitata 16mm plateae caloris caloris in praecepto succidere debet, et 3000W apparatus electus est, apparatus vere 16mm plateae caloris carbon, sed velocitas succidere est solum 0.7m/min, et long a tempora succidendus est calumniam lentibus consumablis, et etiam influent lentibus concentrationis. Potentiam 6000W ad succidendum et processendum recommenditur.

Contenium artificis ab internet est. Si quaestiones habes, contacta me ut deleam illum!

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque