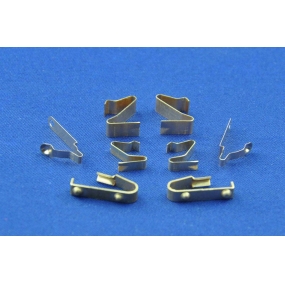

Precision aviation parts machining refers to a machining technology that achieves precision requirements in terms of dimensions, shape, surface roughness, and contour accuracy of the machined parts. Haec technologia processionis graduam develovit et crevit cum developpe supertecnologiae modernae, prima includit diversos modos technicos, sicut milling, turning, polishing, electrochemical machining etc. The commonly used heat treatment methods in the procession of precision aviation parts include the following: Quenching and tempering: This is a preparatory heat treatment process, usually arranged before or after rough machining. Adjusting the hardness and difficulty of the material, the cutting performance of the material can be improved. Fractae extinguerunt et temperatura non facile deformuntur in secessione, quae accuracionem machinae meliora potest Annealing: Annealing is also a preparatory heat treatment process that reduces the hardness of materials, improves cutting performance, reduces cutting force and cutting heat, and thus extends tool life. Praecepta Annealing normale paratur ante machina difficile Normalizatio: Normalizatio est processus aestum tractionis in qua opera ad punctum critical AC3 aut super 30 °C °50 °C calefacetur, et tunc uniforme coolidetur in aere fluentem liberum. Normalizatio potest improvine machinabilitatem materiarum, fortitudinem et gravitatem parterum Carburiatio et extinguitio: Haec processus aestum tractionis cum significantia deformatione, normale ante machinas precision arantur. Carburiatio et extinguitio potest crescere saturem carbon super faciem partium, meliora faciem difficile et resistentiam portare, cum gravitatem et fortitudinem cordis servare Nitriding: Nitriding est processus calefactionis cum minima deformatione, saepe post machinas precision ordinata. In infiltratione atomum nitrogenae in superficiem parterum difficile et resistentia superficie meliora sunt et vita servitutis parterum extenditur Time treatment: The purpose of time treatment is to remove internal stress and reduce workpiece deformation. Tempus trakta in tres categorias divisa potest: natura tempora trakta, artificia tempora trakta, et frigida trakta. Temporabilitate processura generale post maquinas difficiles et ante maquinas precisiis ordinetur; For parts with high precision requirements, another aging treatment can be arranged after semi precision machining.

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole