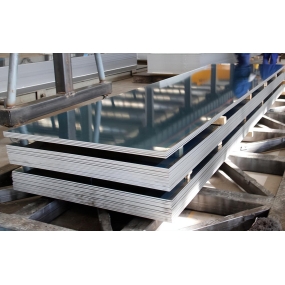

Briefly describe several common surface treatment processes for aluminum stamping parts in hardware stamping factories:

1. Aluminium anodizing

Quando ad meliorem tractionem superficie partium pulserum aluminium est, non est inevitabile mentionare proceduram anodizationis. Anodizatio potest effectuale compensare superficiem duritiam et resistentiam partium pulchritudinis aluminium induere, et multo crescere servationem partium pulchritudinis aluminium, ut produktum pulchrior videtur. Nowadays anodizatio maximus et convenientius methodos superficie tratationis aluminiorum produktorum facta est. Anodizatio refert ad oxidationem electriciae metallorum aut allogum. Aluminum et its alloys form an oxide film on aluminum products (anodes) under the action of external current in corresponding electrolytes and specific process conditions.

In addition, aluminium stamping parts can also be anodized to obtain various colored appearances, further expanding the use of aluminium stamping parts.

2. Sandblasting

Sandblasting est generale procedentia central super faciem tractionis partium stampingorum aluminium in fabricas stampingorum hardware. Sandblasting parts of aluminum stamping can effectively remove burns and oil stains on the surface, improve the cleanness of the aluminum surface, and obtain products with different surface roughness by controlling the sandblasting material. Cum sanda blastit, produktum functionalitatem significantly improvetur. In subsequent surface treatment process, it is also possible to add adhesion between aluminium stamping parts and coatings, making the product more durable and beautiful.

3. Polishing

Aluminium pulsatı parçaları aynı şekilde etkisi olabilir, ürünün kalitesini ve güzelliğini çok uzlaştırabilir. However, a result of the characteristics of aluminum products, polishing of aluminum stamping parts is relatively rare. If no other surface treatment is done after polishing, the durability will be relatively low. Difficile est deponere effectum speculatorum aluminium stampingorum longo post pulsationem. Generalis, productores, qui speculatorum effectum requirant, adnuntiati sunt velle stainless utili.

4

Multa genus sculptilium partibus aluminium est, includit rectum sculptile, randomum sculptile, spirale sculptile, et sculptile. Post drawing, clear and subtle traces can be seen on the surface of the aluminum stamping parts, giving the product a glowing silk like feeling.

Basically, the aluminum stamping parts require surface treatment after processing, but the choice of treatment method depends on the specific requirements of the customer. In absentia negotiorum, fabrica metalla pulsere generale anodizationem eligit.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque