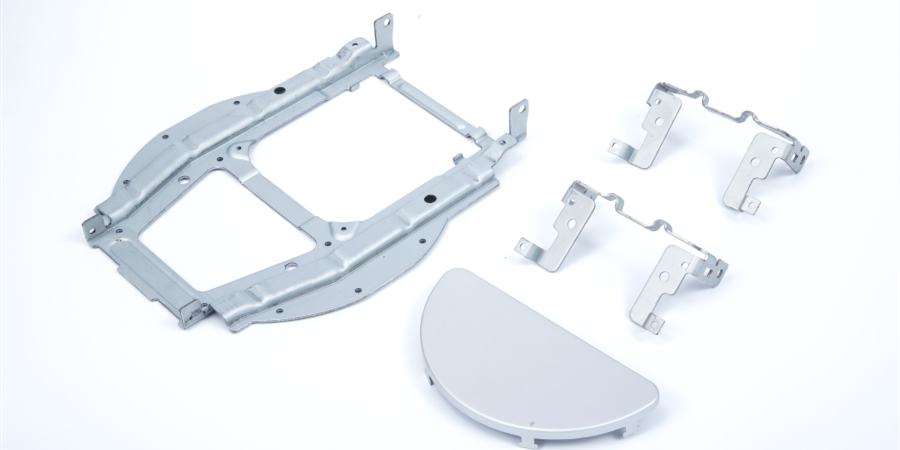

Partibus sculptilibus profundis partibus sunt sculptilibus qui fabricantur metallos lapides in formas cylindricas aut cisternas per sculptilibus, anulos traxerunt aut moldas metallos. A facie deformationis metallorum, fabrica metallorum stampionis saepe calore formatur pro productione partibus profundis attributionis. Haec est calefactum billetum usque ad tenendum, placuit illum in mold a pro molda, et constituere strukturam frigidam intra molda ut certem quod temperatura inferiora est. Hoc facit billetum frigidam temporali ut certem quod formam profundis attributionis part is fixerit.

Haec methodo stampionis amplius utilizata est in multis regionibus, et principum opus eius similis est ei in processione stampionis general is. Sed, procedus stampionis profunda est melior quam procedus stampionis generalis et habet quattuor avantias maximas.

1. Qualitate maxima finis

The product quality of deep drawn stamping parts is well known in most hardware stamping factories, because there is mold production and assistance during processing, so the processed products are very precise in shape and size. Moreover, in the production process of molds, their service life is also very long, so the quality of deep drawn stamping parts produced in the market is high-end. @ 000@ 000 2. Scope of application

Scala singulorum partem amplius traxitae part is varia est, et partes producentes habent scalas precisas valde. Est utile in vita nostra cotidiana et productione industria, sicut instrumenta electronica domus, fabricatione raedarum, et horologia quae indumur. Stoga, hoc typus equipamenti in multis locis utilitur. ●

3. Simple and efficient

In terms of overall process control, each step in the production of deep drawing stamping parts is controlled like a production line, so the complexity of personnel operation is much simpler than that of general stamping methods. Maintenantia armantium consolatoris est, et effectus profundis pulserum pulserum meliora est, sublime in signatione et interiora fortitudine.

4. Energy conservation and environmental protection

Energy conservation and environmental protection are the advantages of deep drawing stamping parts, mainly due to their special manufacturing process. During the processing, many materials are used reasonably and do not require too much energy consumption. This not only saves energy but also reduces production costs. Therefore, it can improve the efficiency of many hardware stamping factories and pursue energy conservation and environmental protection in modern society.

This article is from EMAR Mold Co., Ltd. For more EMAR related information, please click on www.sjt-ic.com,

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque