Fixture processing refers to the manufacturing of clamping, positioning, supporting and testing devices necessary for the production of various machines, machinery, electrical equipment, instruments, light industrial products, and other means of production. Dicetur quod fixturae industria industria non placendam acturi sunt. Processus fixturae est step essential in productione, et qualitate eius crucial ad qualitatem produkti est.

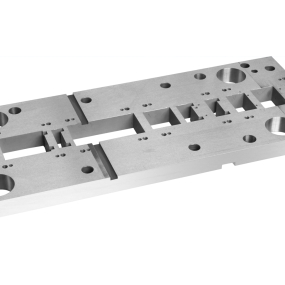

Fixtures are extremely important tools in the mechanical manufacturing industry. They are essential and important equipment in the production line, whose function is to ensure product processing accuracy, process requirements, and mass production efficiency, and provide strong support for subsequent product quality inspection and repair. Contentus processionis fixturis divites est valde, requiring mastery of various processing and forming technologies, and the need to manufacture different fixtures according to different processing and design requirements.

Technologia processionis fixturis est tecnologia cruciale quae directo ad qualitatem et efficientiam produktorum affectat. Facultatio fixturae quaedam technicam processationis requirit, quasi fabricationem, frigidam et caligationem, fabricationem metallorum, processionem precisionem et cetera. The selection of processing technology also requires in-depth thinking and analysis based on various factors such as the material, structure, and operational requirements of the fixture. At the same time, fixture processing also relies on a series of processing equipment, such as machining centres, CNC lathes, grinders, drilling machines, milling machines, etc.

Detailed and precise machining design is also required during the fixture processing. Usually, the design of fixtures needs to be combined with the process flow and requirements of product processing, develop necessary processing techniques, and design corresponding fixture structures and shapes based on specific requirements and parameter requirements. Processing design also needs to pay attention to the reliability, stability and accuracy of fixtures to ensure their service life and reasonable cost-efficiency.

Qualitate processionis fixturis valde important is est, quia directo ad qualitatem et effectivitatem produkti influent. At the same time, to ensure the quality of the fixture, a series of detection methods such as coordinate measurement, optical measurement, white light interference detection, etc. need to be adopted.

The purpose of fixture processing is to meet production needs, improve processing efficiency and product quality, while gradually optimizing processing costs. The manufacturing of fixtures is a very comprehensive process that requires full consideration of various factors. Therefore, for fixture processors, they need to have a wide range of knowledge and skills, such as mechanical processing, metal processing, design, production management, etc., to ensure short fixture processing cycles, stable quality, and controllable costs. At the same time, fixture processing technology also needs to be constantly updated to meet the different needs and applications of different industries.

English

English Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque