The commonly used process for automated equipment parts processing is CAD/CAM technology for automated machining. Procedus principis est sicut:

1. Part design and model establishment

Prima gradus in processione partes cum automata equipationibus est design and model establishment. Haec est opus et programatio software CAD, quod propositur bonam basem pro subsequente design et processione routes.

2. Generate machining paths

Diagrammas software CAD semper tresdimensionales modellae sunt, quas eas in diagramas duodedimensionales convertere debent ut semitas machinatorium pro software CAM generat. Software CAM utilizat programmationem computatorium ad unificandum viam machinarum instrumenti machinarum et typum machinarum, codicem G pro instrumentis machinarum CNC generabitur.

3. Scribe codicem NC

Postquam vectem in software CAM generare potest codis G manum scribere per editorem PC. Codice NC est executor execution is viae machinae, qui convertit prosessos, quales grinding et milling ab computatorio in instruktiones machinae. Post codicem G scribere potes processere.

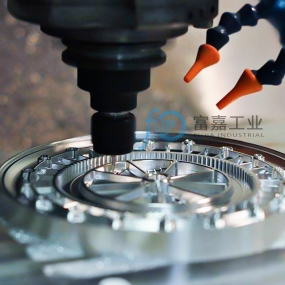

4. Processing components

Using CNC machine tools to execute G-code, the machine is controlled to complete part machining according to a predeterminated path and speed during the machining process. Si errora tolerantia programmae considerata est in hoc processo, potest evadere occurrentiam aliorum unexpectorum situationum.

5. Inspection and Testing

Post impletionem procedentis machinae, part is inspectionis et testis requiuntur. Hoc per ecclesiam et repetitiones mensuras implebitur. Secundo, necesse est probare partes per factores such as temperature and part stiffness, and promptly address any problems found.

3,Application fields of automated equipment parts processing

The application fields of automated equipment parts processing are very extensive, covering various fields of manufacturing. Among them, mechanical manufacturing, aerospace, automotive industry, electronic technology, and medical device industry are the most important areas of application.

1. Mechanical manufacturing

Mechanical manufacturing is the most important application field of automated equipment parts processing. In mechanical manufacturing, automated equipment for parts processing can significantly reduce labor costs and improve processing efficiency, while ensuring high precision and consistency of products.

2. Aerospace

In aerospace agro precisio partibus altissima sunt. In this case, automated equipment parts processing can perfectly meet this requirement, while also improving the operational efficiency of the aircraft and reducing costs.

3. Automotive industry

In the automotive industry, automated equipment parts processing also plays a huge role. The machining accuracy of automotive parts directly affects the performance and safety of the car, while automated equipment parts machining can ensure high-quality and high standard manufacturing of automotive parts.

4. Technology Electronic

In the electronic technology industry, automated equipment parts processing can improve processing accuracy and production efficiency through innovative mechanisms such as continuous processing, rapid flipping, and multi station one-stop, further achieving product specialization, optimization, and batch production.

5. Medical devices

Precisio, qualitate, et salutem componentium in industria medicorum habent signum influentiam super vitam suam. Instrumentos automaticos processionis optima fabricationis et consistentiam componentium possunt, ut securitatem et reliabilitatem dispositivorum medicorum assecurantur.

English

English Spanish

Spanish Arabic

Arabic Spanish Basque

Spanish Basque Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese 简体中文

简体中文 Haitian Creole

Haitian Creole