Scisne fluxum processionis maculae?

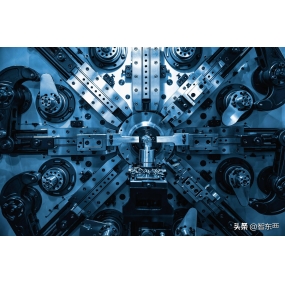

The process flow of rack machining refers to the steps of manufacturing and processing works pieces or parts. During the operation, mechanical processing methods can be used to directly change the shape, size, and surface quality of the blank, making it a machining process for the part. De procedura processionis. Exemplo, machinatio parterum ordinarum machinationem difficilem, machinationem precision, assembly, inspectionem, et packaging, quae est procedus machinationis general. Large scale automatic welding is the process of achieving atomic bonding of the material of the workpiece through heating, pressure, or a combination of both, with or without filler materials. Performing corresponding heat treatment processes on workpieces is beneficial for improving their hardness, wearing resistance, and strength, greatly enhancing their accuracy and service life.

Contenium principium procurationis fundamenti est cambiare formam, granditudinem, positionem relativam et proprietatem objectis manus administracionis industriae, ut perfectos aut semifinitos produktos fiant. Descriptio singulorum graduum et procedentium detaila est. Exemplo, machina difficile mentionata supra potest industriam vacuum, grinding, etc. Precisio machina divisa potest in latus, fitters, miling machinas, etc. Omne passum datum detaliorum requirit, sicut quanta difficile attingere debet et quanta tolerans attingere debet.

In fermento magnorum pallium, personel technic determinabit fluxum accipientem proceduram based on the quantity of products, equipment conditions, and the quality of workers, and write the relevant content in the process documents, called process regulations, which are more targeted. Omnia fabrica forsitan est, quia facta situatio variatur.

Rack processing

Partes metallis lapides sunt componentes metallos tenues qui exterior per punching CNC, bending, stretching, and other processes can be processed. Paramque partis cum densitate constantes in manufacturo procedentibus definitur. Propter hoc, castimenta, fraudulentia, partes mecanica, etc. Processus metallis lapidis processus metallis appellatur. Exemplo tabulas ut faciant chiminum, rubiculum ferrum, tankicum olei et tankicum olei, fluctum ventilationis, arcum et caput, area circularum, funellum etc. Procedores principes include cutting, bending, bending, bending, welding, riveting, etc. Aliquid scientia geometrica. Partes metallis lapides sunt partes metallis thinas quae simul per stampionem, bending, stretching, et alias metodes procedere possunt. Exemplo, exterior pellis ferreorum raedae est parte metalla folia, et aliud culinae calicis calicis calicis calicis calicis similiter partibus metallis calicis sunt. Fabrica fabrica fabrica fabrica faciens credit quia fabrica metalla fabrica est usus tres gradus importantium fabricationis metallorum Dongguan, id est cuta, punching/cutting, et folding. Attributiae fabricationis metallorum fabricationis Dongguan: 1. Fertilitate partium metallorum inferiorum fertilitate multo adjusta est; 2. Interea inter partes metallis original is et instrumentum originalis 0,3mm est. 3. 4. Holes in inferior sheet metal parts. Excellent sheet metal parts require mechanized production, with smooth welding points and no burrs on the edges; 5. Excellent sheet metals parts require a high level of attention to the baking painting process, requiring uniform weight, strong adhesion and good water-proof and antioxidant properties.

English

English Spanish

Spanish Arabic

Arabic Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German French

French Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latvian

Latvian Romanian

Romanian Maltese

Maltese Malay

Malay Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque